Automatic Copper Chips Briquetter Machine

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | SHANGHAI |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | SHANGHAI |

Model No.: Y83-250

Brand: YMSRECYCLING

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Motor, Pressure Vessel, Pump

Warranty Period: 1 Year

Core Selling Point: Automatic

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Manufacturing Plant, Other

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Brazil, Russia, Thailand, Australia, Ukraine

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Application: Metal Chips/Swarf/Turnings Briquetting

Maximum Force: 250ton

Briquetting Efficiency: 3-4 Briquettes/Min

Voltage: 380v/3phase/50hz; Support Customized

Operation: Plc Control Fully Automatic Operation

System Working Pressure: 20~22mpa

Oil Cooling: Water Cooler; Air Cooling Is Optional

Hydraulic Oil: ~1000l

Briquette Diameter Size: 80-110mm

Briquetting Capacity: 320~460kg/H (Copper Chips)

What is the Automatic Copper Chips Briquetter Machine? The Metal Briquetting machine is mainly used to press loose copper chips, shavings and turnings into high-density briquettes without additives or binders.

The Copper Briquetting Press could press the copper chips into briquettes with various sizes for option, high-density compression, compact and strong and resistant to falling.

The Metal Briquetting Press machine plays an important role in metal recycling, especial in re-melting the copper and eliminate pollution from the atmosphere.

-Automatic Copper Chips Briquetter Machine-YMSRECYCLING

Application of Y83 Metal Briquetting Press

Y83 series hydraulic metal briquetting press is used for cold pressing of ductile non-ferrous and ferrous metal scraps into metal briquettes, forming compact cylindrical or cuboid formats.

Metal briquetting press could press a wide range of metal chips/swarf/turnings.

Metal powder, swarf, turnings, chips, such as cast iron, aluminium, copper, steel, brass, zinc, bronze, titanium, magnesium, lead and other machining scraps.

Various sizes for option, high-density compression, compact and strong and resistant to falling.

Convenient for storage and transportation, better melting effect by reheating, reducing melting loss.

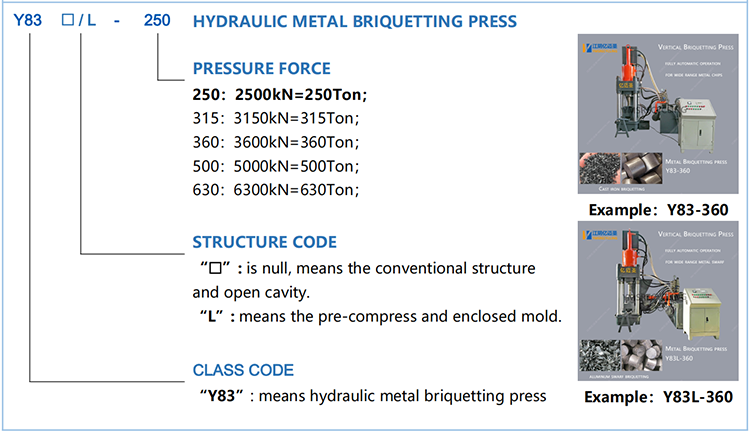

Description of Y83 Metal Briquetting Press

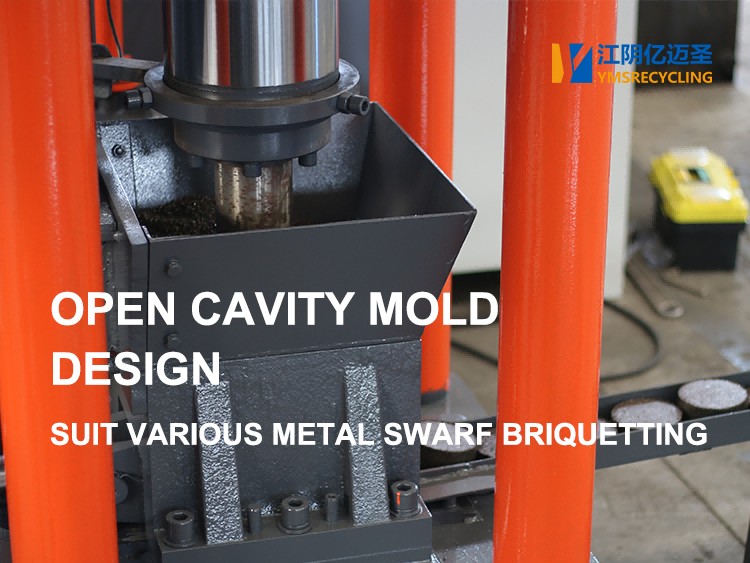

The Y83 metal briquetting press mostly with an open pressing mold cavity structure.

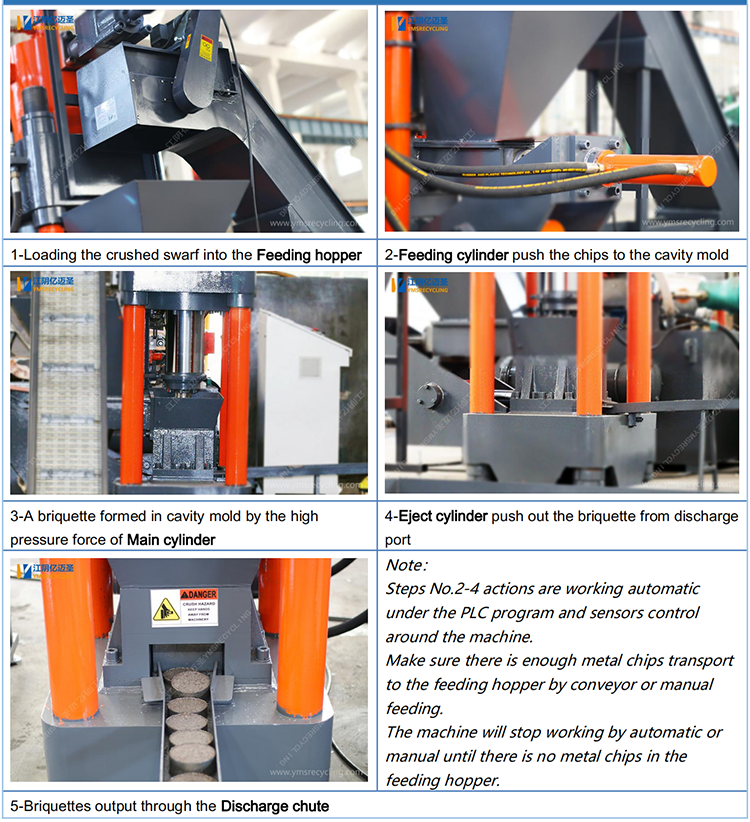

The Feeding cylinder pushes the metal chips into the mold cavity from the Feeding hopper, which is compressed into a briquette in the mold cavity by the Main cylinder, then the Eject cylinder ejects the briquettes.

(Suitable for finely crushed and fluid metal scrap materials)

Working Steps-Y83 METAL BRIQUETTING PRESS

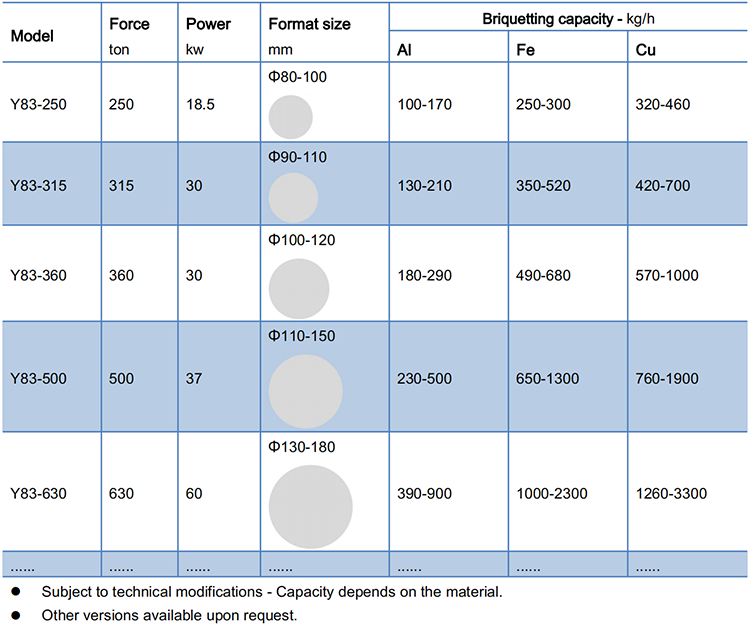

Models -Y83 Metal Briquetting Press

We provide a variety of models of Horizontal Briquetting Press, which support 24 hours fully automatic working environment.

YMSRECYCLING offer economical and effective solutions to help you to process different metal scraps.

The equipment can be customized and extended according to the actual needs of customers on site.

Please provide the required requirements in consultation.

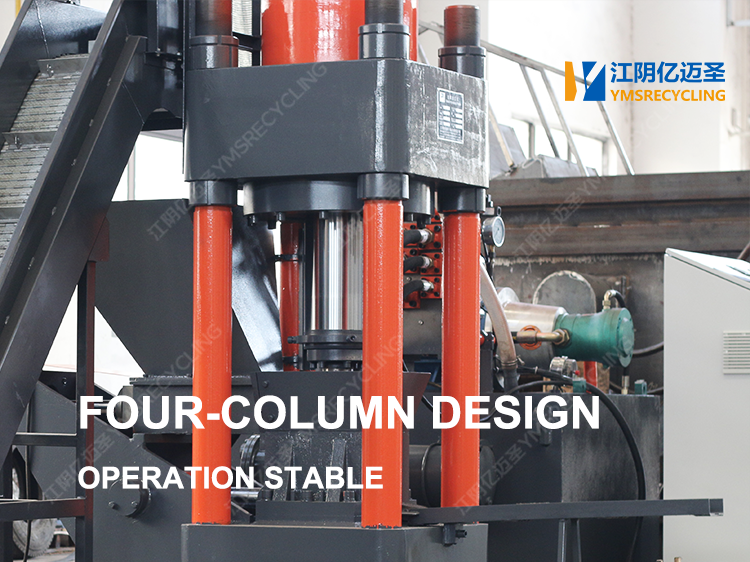

Features of Y83 Metal Briquetting Press

-Automatic operation, Save labor & More efficient

-Four-Column Design, Operation satable

-Hydraulic unit, Better power performance

-Industrial control cabinets, Doing smart & Safety work

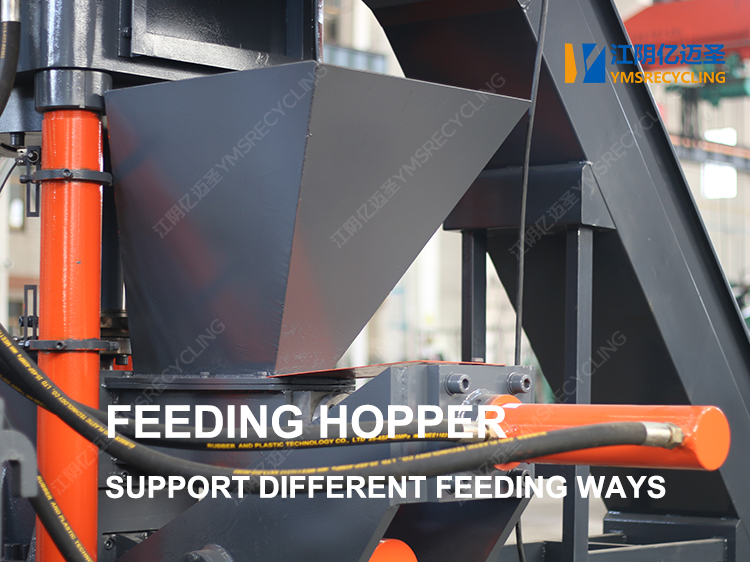

-Feeding hopper, Support different feeding ways

-Open cavity mold design, Suit various metal swaf briquetting

-Front discharge chute, For easy loading and storage

-Support customization, Up your request

Service & Support

| Machine Acceptance |

We YMSRECYCLING ensure that the equipment provided meets the requirements for product safety and reliable operation, and shall be fully responsible for the design, manufacturing, supply, testing, packing and commissioning of the equipment.

The firm guarantees the machine hereby described has been designed to comply with all regulations in force, particularly safety and health regulations. All the machines will be tested and give a test report before shipping.

Spare Parts

YMSRECYCLING delivers parts for Recycling Machines to any location in the world. Because we understand the importance of good recycling machine performance. We will be delighted to advise you about the parts required to keep your recycling machines in optimum condition.

| Installation & Operation Training |

YMSRECYCLING offers purpose-designed training courses for your employees. Which can be held at your site or our facility. To guarantee optimum use of your recycling machine. All YMSRECYCLING machines are easy to operate.

Topics such as installation, guidance and training of the equipment, safety operation, service and maintenance are also discussed during the training course.

| Warranty |

To maintain a warranty, the machine must be serviced according to the manufacturer's recommendations outlined in procedures for warranty claims and the service booklet. The warranty covers a period of 12 months, Wearing parts cover a period of 3 months.

The buyer is entitled to the free replacement of faulty parts.

The warranty does not cover damage caused by falls or careless handling of the machine, incorrect operation and noncompliance with the maintenance rules. Any tampering with the machine, especially with its safety devices, automatically voids the warranty.

YMSRECYCLING will be freed from any responsibility. No claim for damages shall be accepted in cases where the machine has been lying idle for a long period of time.

FAQ

|

Q: Are you a factory or trade company? |

A: YMSRECYCLING is a manufacturer located in Jiangyin City, Jiangsu Province, China. Our team consists of excellent engineers, technicians, and sales service personnel dedicated to designing and manufacturing hydraulic machines for recycling.

|

Q: Can I get any tests to check the quality before the order? |

|

Q: Can the machines be customized to our needs, such as putting our logo on them? |

A: With 20 years of experience in designing and manufacturing hydraulic machines, we have the ability to customize them to suit your specific circumstances. We can also add your logo to the machines upon request.

|

Q: After placing an order, will you provide installation or training services? |

A: We are happy to offer online assistance or arrange for our engineers to provide on-site support to ensure a smooth installation process and offer training services.

|

Q: How do you prevent damage during long-term shipping? |

A: All our machines are carefully film wrapped before shipping, and all machines and parts are fixed with steel wire to prevent damage during transportation.

|

Q: What payment options do you offer? |

A: We offer various payment methods, including Alibaba Pay, Western Union, T/T, and L/C. You can rest assured that your payment and business with us will be safe and secure!

Contact Us for the Best Recycling Solution

Sales Department: +86-15950122559 (Mr. Jack Zhou)

At YMSRECYCLING, our team of specialists is dedicated to providing you with the best solution for your recycling needs. From production rates to running costs and shearing technologies, we will work with you to ensure your requirements are met. Contact us now to get started.

For more information on our Catalytic Converter Decanner Machine, please don't hesitate to contact us now. Our knowledgeable team is ready to assist you and answer any questions you may have.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.