In today's world, industrial processes generate vast amounts of metal waste, which, if not managed properly, can have detrimental effects on both the environment and resource efficiency. Among the various forms of metal waste, scrap metal chips are one of the most common by-products in manufacturing and machining industries. These chips, produced during the cutting, grinding, or machining of metals, are often discarded in large quantities, taking up valuable space and leading to significant material wastage. However, advancements in technology have introduced efficient solutions for the recycling of these scrap metal chips, with the scrap metal chips briquetting machine emerging as a game-changer.

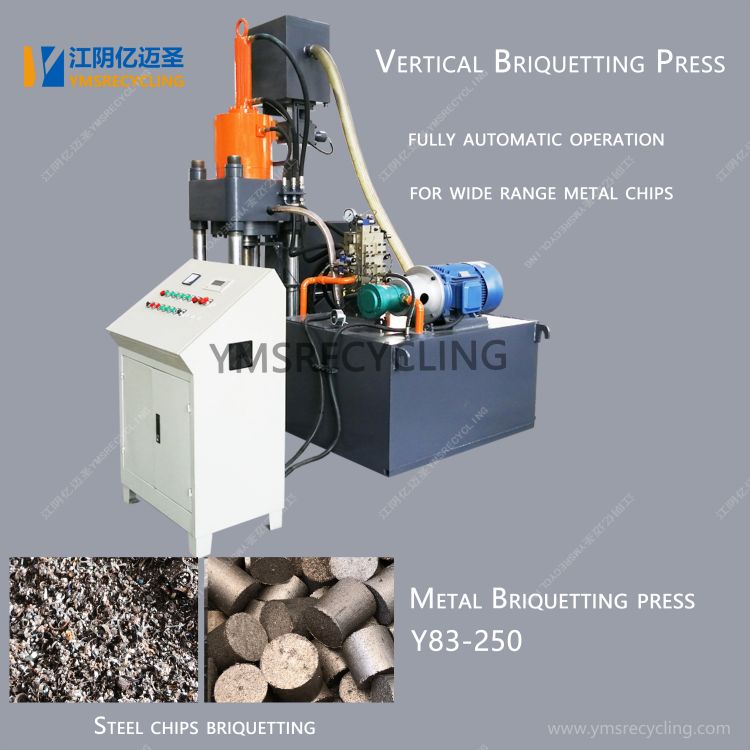

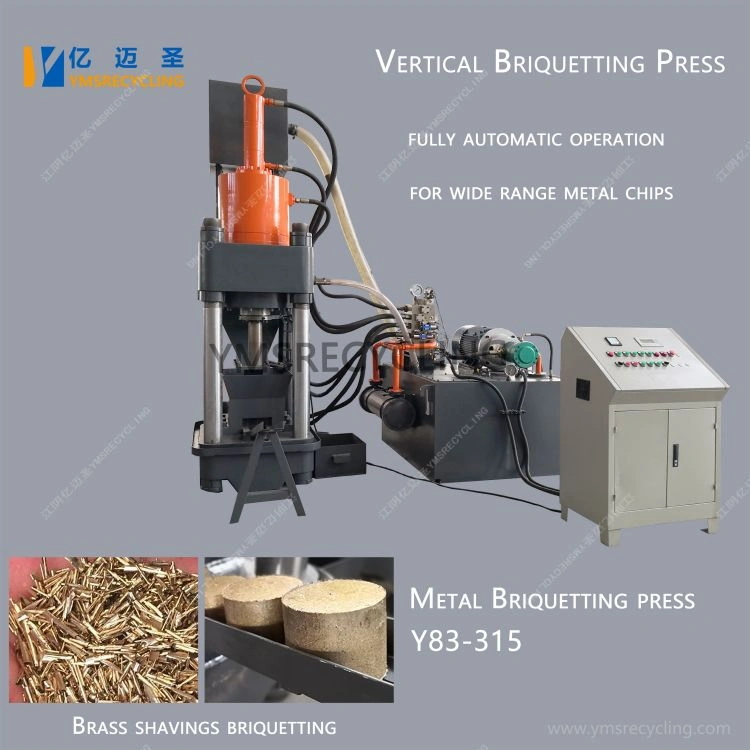

Briquetting is a process that involves compressing loose metal chips into dense, compacted forms known as briquettes. These briquettes are more manageable, easier to transport, and, most importantly, can be melted down and reused in the production of new metal products. The scrap metal chips briquetting machine is at the heart of this process, transforming the traditionally wasteful and bulky metal scrap into a more useful and valuable resource. The machine operates by applying high pressure to the metal chips, binding them together into a solid form, typically without the need for binders or adhesives.

One of the most significant benefits of this process is that it helps save space. Metal chips, which are often left in loose piles, consume a lot of space in workshops or factories, making them difficult to handle and store. Briquetting reduces this space by consolidating the chips into compact blocks, allowing for efficient storage and easier transportation to recycling plants or smelting facilities.

The scrap metal chips briquetting machine offers a multitude of benefits, especially when it comes to improving the efficiency of industrial processes. In addition to reducing waste, it plays a pivotal role in enhancing the overall sustainability of metalworking industries. The briquettes produced can be reused in metal smelting operations, reducing the need for raw material extraction. This not only decreases the environmental impact of mining activities but also conserves natural resources, helping industries meet sustainability goals.

Another advantage of briquetting is its ability to reduce energy consumption. Metal recycling through briquetting allows industries to use the same raw materials multiple times. By reusing scrap metal, companies can reduce their dependence on primary metal production, which is often energy-intensive and environmentally harmful. This shift towards recycling and reuse helps companies lower their carbon footprint while contributing to a more circular economy.

From an economic perspective, the scrap metal chips briquetting machine offers substantial cost savings. Scrap metal in its loose form can be difficult to transport and may incur additional processing costs when it is sent to a recycling facility. However, by turning scrap into briquettes, the metal becomes easier to handle, reducing transportation costs and making it more attractive for buyers. This also makes it possible to sell scrap metal at a higher price, as briquettes are more desirable to recycling centers due to their ease of handling and uniform size.