I. Introduction

In an era increasingly defined by environmental consciousness and resource efficiency, the importance of recycling and effective waste management has never been more pronounced. Amidst the vast machinery and intricate processes that underpin modern recycling, one device stands out for its pivotal role in transforming metallic waste into valuable raw material: the scrap metal baler.

At its core, a scrap metal baler is a powerful hydraulic machine designed to compress loose metal scraps into dense, manageable blocks known as bales. This seemingly simple function is, in fact, a cornerstone of the metal recycling industry, enabling the efficient collection, transportation, and processing of everything from discarded car parts to industrial offcuts. By compacting these unwieldy materials, balers dramatically reduce their volume, leading to significant benefits in terms of space optimization, operational efficiency, and enhanced safety. This article will delve into the world of scrap metal balers, exploring their various types, fundamental functions, myriad benefits, and profound impact on both the economy and the environment.

II. Understanding the Scrap Metal Baler

A. Basic Principle of Operation

The operation of a scrap metal baler is rooted in the principle of hydraulic compression. Loose metal scrap is fed into a compaction chamber. A powerful hydraulic ram then exerts immense pressure, pushing the material against a fixed wall or another ram, progressively reducing its volume. This process continues until the metal is compressed into a compact, high-density bale.

Key components facilitating this process include:

- Compaction Chamber: The area where the metal is loaded and compressed.

- Hydraulic Ram(s): The primary moving part(s) that apply pressure. Balers can have one, two, or even three rams depending on their design (e.g., side-eject, front-eject).

- Hydraulic System: Comprising pumps, cylinders, valves, and a fluid reservoir, this system generates and controls the immense force required for compaction.

- Control Panel: Allows operators to manage the baler's functions, including loading, compaction cycles, and bale ejection.

B. Types of Scrap Metal Balers

Scrap metal balers come in various configurations, each suited to different scales of operation and types of material:

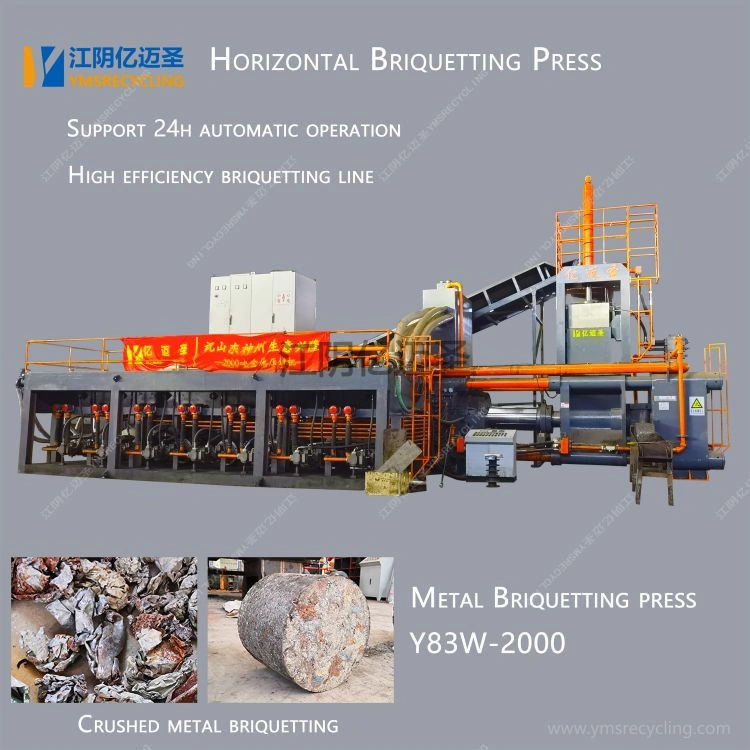

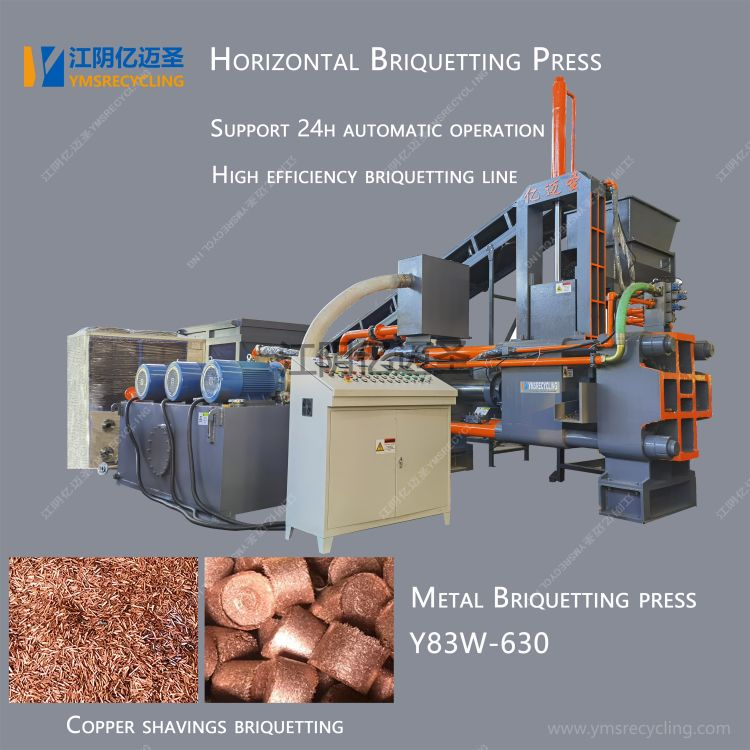

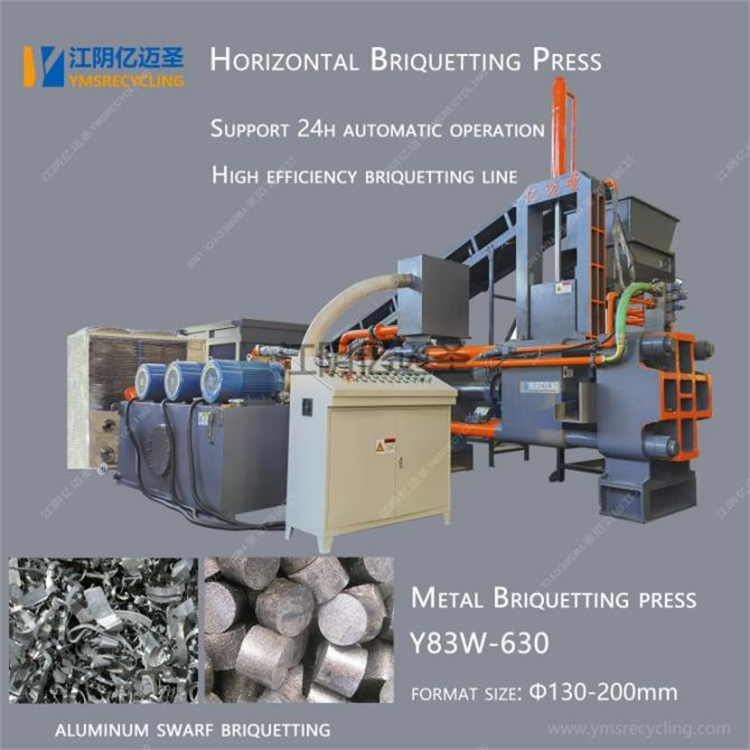

- Horizontal Balers:

- Description and Applications: These balers feature a horizontally oriented compaction chamber and ram. They are typically larger and more robust, designed for high-volume processing of various metals, including steel, aluminum, and copper. They are commonly found in large recycling facilities, scrap yards, and industrial manufacturing plants where significant quantities of scrap are generated.

- Advantages: High throughput, ability to handle larger and more irregular pieces of scrap, often equipped with automatic feeding systems.

- Disadvantages: Require more floor space, generally higher initial investment.

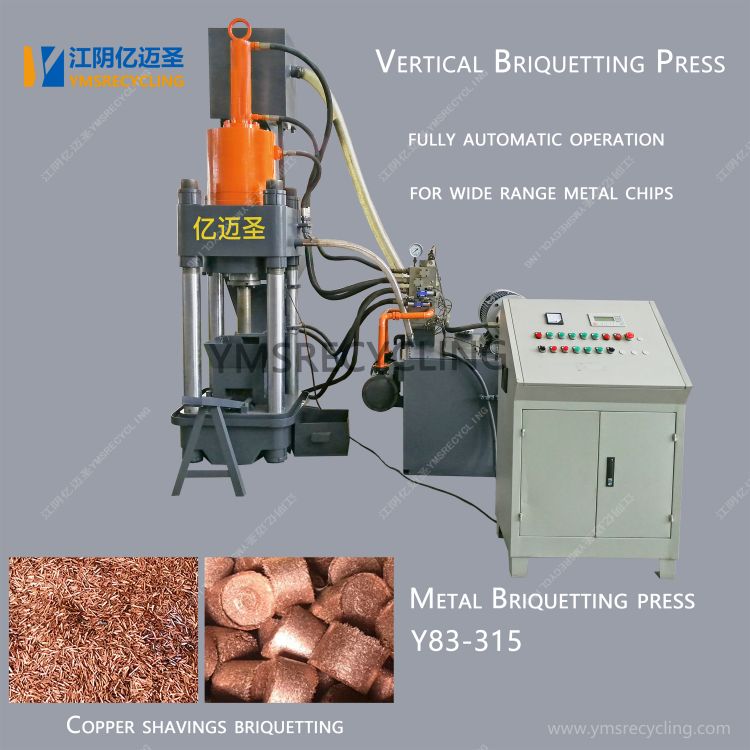

- Vertical Balers:

- Description and Applications: Characterized by a vertically oriented compaction chamber, these balers are smaller and more compact. They are ideal for businesses with limited space or those generating smaller volumes of scrap, such as workshops, small fabrication shops, or retail outlets dealing with aluminum cans or light gauge metals.

- Advantages: Space-saving footprint, lower cost, simpler operation.

- Disadvantages: Lower throughput, generally limited to lighter gauge and smaller scrap pieces, often require manual feeding.

- Automatic vs. Manual Balers:

- Manual Balers: Require an operator to manually load the scrap, initiate the compaction cycle, and often tie off the bales. They are typically vertical balers and are suitable for smaller operations.

- Automatic Balers: Feature conveyor systems for continuous feeding, automated compaction cycles, and often automatic bale tying and ejection. These are predominantly horizontal balers, designed for continuous, high-volume operations with minimal manual intervention.

- Suitability: Manual balers suit intermittent, lower-volume needs, while automatic balers are essential for large-scale, continuous processing where labor efficiency is paramount.

- Specialized Balers:

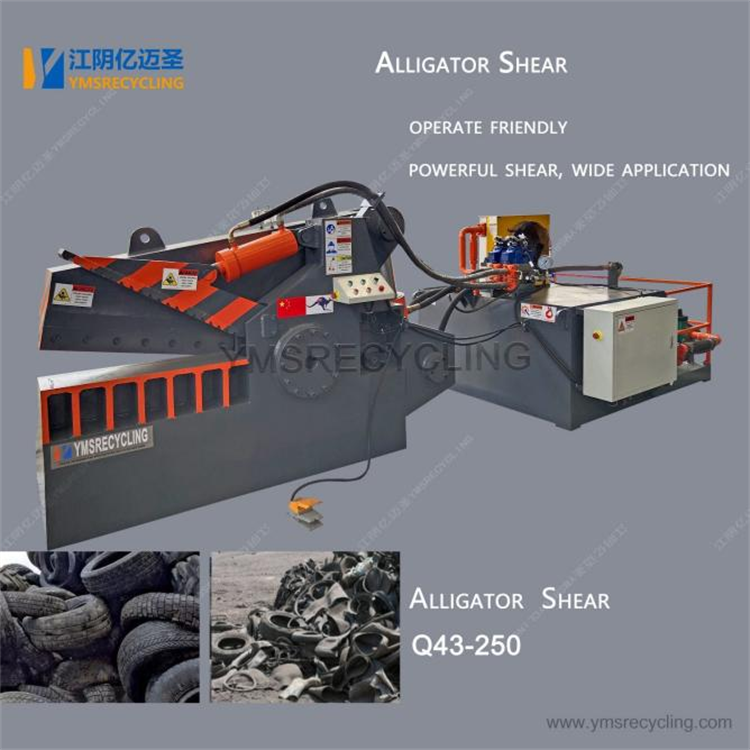

- Shear Balers: These machines combine the functions of baling and shearing. They can compress large, bulky scrap and then shear it into smaller, more manageable pieces or bales, making them highly versatile for processing heavy and irregular scrap.

- Briquetting Machines: While not strictly "balers," briquetting machines compress metal chips, turnings, and swarf (fine metal shavings) into dense, solid briquettes. This process is crucial for recovering valuable oils and and coolants from the scrap and making the fine material easier to melt.

III. The Benefits of Using a Scrap Metal Baler

The adoption of scrap metal balers offers a multitude of advantages that resonate throughout the recycling supply chain and beyond.

A. Space Optimization

One of the most immediate and tangible benefits is the dramatic reduction in the volume of scrap metal. Loose, bulky scrap consumes vast amounts of valuable floor space in warehouses, scrap yards, and industrial facilities. By compressing this material into dense bales, balers can reduce its volume by up to 90% or more. This optimization frees up critical storage space, improves site organization, and allows for more efficient use of existing infrastructure.

B. Increased Efficiency and Productivity

Baled metal is significantly easier and faster to handle than loose scrap. Loading and unloading operations become streamlined, reducing the time and labor required. This increased efficiency translates directly into higher productivity for recycling operations, allowing them to process larger quantities of material in less time. The consistent size and density of bales also facilitate automated handling systems.

C. Enhanced Safety

Loose scrap metal, often sharp, jagged, and unstable, poses considerable safety risks to workers. Handling unbaled metal can lead to cuts, punctures, and crush injuries. Baling the metal transforms it into a stable, compact unit, significantly reducing these hazards. Bales are easier and safer to stack, move with forklifts or cranes, and transport, creating a safer working environment.

D. Economic Advantages

The economic benefits of using scrap metal balers are substantial:

- Reduced Transportation Costs: Denser bales mean more material can be loaded onto each truck or shipping container. This maximizes payload capacity, leading to fewer trips, lower fuel consumption, and significant savings on transportation costs.

- Higher Scrap Value: Many scrap metal buyers prefer or offer higher prices for baled metal due to its ease of handling, reduced contamination, and higher density, which makes it more efficient for melting processes. For certain metals, baling can also help maintain purity if materials are sorted before compaction.

- Increased Revenue: By making the recycling process more efficient and cost-effective, balers directly contribute to increased profitability for businesses involved in metal recycling.

E. Environmental Impact

While detailed later, it's worth noting here that balers play a crucial role in environmental sustainability. By facilitating efficient recycling, they contribute to waste reduction and the conservation of natural resources.

IV. Applications and Materials Handled

Scrap metal balers are indispensable tools across a diverse range of industries:

A. Industries that Utilize Balers

- Recycling Facilities: These are the primary users, processing vast quantities of mixed ferrous and non-ferrous metals from various sources.

- Manufacturing Plants: Industries such as automotive, aerospace, fabrication, and stamping operations generate significant amounts of metal offcuts, turnings, and punch-outs, which are efficiently managed by on-site balers.

- Demolition and Construction: Projects involving the dismantling of old structures generate large volumes of rebar, structural steel, and other metallic debris that require compaction for removal and recycling.

- Scrap Yards: These facilities serve as collection points for various metals and rely on balers to process and prepare materials for shipment to smelters and foundries.

B. Types of Metal Handled

Scrap metal balers are versatile enough to handle a wide array of metallic materials:

- Ferrous Metals: These include iron and its alloys, predominantly steel. Examples range from car bodies, white goods (appliances), rebar, and industrial steel offcuts.

- Non-Ferrous Metals: These are metals that do not contain iron, such as aluminum (cans, window frames, industrial profiles), copper (wires, pipes, fittings), brass, and sometimes lead or zinc.

- Mixed Metals and Challenges: While balers can compress mixed metals, effective recycling often requires sorting metals by type beforehand to maintain purity and maximize their value. Contamination can reduce the value of the baled material.

V. Key Features to Consider When Choosing a Baler

Selecting the right scrap metal baler is crucial for optimizing operations. Several key features warrant careful consideration:

| Feature | Description |

|---|---|

| Capacity and Throughput | This refers to the volume of material the baler can process per hour or shift. It's vital to match the baler's capacity to the expected volume of scrap generation. |

| Bale Size and Density | The dimensions and weight of the finished bales are important for transportation, storage, and meeting the specifications of scrap buyers. Denser bales are generally more desirable. |

| Power Source | Balers can be electric (common for stationary indoor units) or diesel-powered (offering more mobility for outdoor or remote operations). |

| Automation Level | Deciding between manual, semi-automatic, or fully automatic operation depends on labor availability, desired throughput, and budget. |

| Durability and Construction Materials | Given the demanding nature of compressing metal, the baler's construction quality, material strength, and component robustness are paramount for longevity and reliability. |

| Safety Features | Modern balers should include essential safety mechanisms such as emergency stop buttons, interlocks, and protective guarding to ensure operator safety. |

| Maintenance and Support | Availability of spare parts, technical support, and ease of maintenance are critical for minimizing downtime and ensuring continuous operation. |

VI. Maintenance and Longevity

Proper maintenance is paramount to ensuring the longevity, efficiency, and safe operation of a scrap metal baler.

A. Routine Maintenance Tasks

Regular preventative maintenance is key:

- Cleaning: Removing accumulated metal dust, debris, and contaminants from the chamber, rams, and hydraulic components.

- Lubrication: Applying grease to moving parts and pivot points to reduce friction and wear.

- Hydraulic Fluid Checks: Regularly inspecting hydraulic fluid levels and quality, and changing filters as recommended by the manufacturer to prevent system contamination and wear.

- Inspections: Checking for loose bolts, worn hoses, leaks, and signs of structural fatigue.

B. Common Issues and Troubleshooting

Common issues can include hydraulic leaks, ram misalignment, electrical faults, or sensor malfunctions. Many minor issues can be resolved through basic troubleshooting steps outlined in the operator's manual. However, more complex problems require expert intervention.

C. Importance of Professional Servicing

Beyond routine checks, professional servicing by qualified technicians is essential for comprehensive inspections, calibration, and addressing complex mechanical or hydraulic issues. Scheduled professional maintenance helps prevent major breakdowns and extends the baler's operational life.

D. Tips for Maximizing Lifespan

- Adhere strictly to the manufacturer's maintenance schedule.

- Train operators thoroughly on proper usage and basic troubleshooting.

- Avoid overloading the baler or attempting to compress materials it is not designed for.

- Use high-quality hydraulic fluids and replacement parts.

VII. The Environmental Impact of Scrap Metal Balers

The environmental contribution of scrap metal balers is significant, positioning them as vital tools in the global push towards sustainability.

A. Role in the Circular Economy

Scrap metal balers are a critical link in the circular economy, a model of production and consumption that involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products for as long as possible. By efficiently preparing scrap metal for recycling, balers enable metals to be re-introduced into the manufacturing cycle, reducing the reliance on virgin raw materials. This process:

- Reduces Reliance on Virgin Resources: Mining and processing new metals are resource-intensive activities. Recycling significantly lessens the need for these primary resources, conserving finite natural deposits.

- Lower Energy Consumption: Producing new metals from recycled scrap generally requires substantially less energy than extracting and refining them from ore. For instance, recycling aluminum uses about 95% less energy than producing it from bauxite, and steel recycling saves about 75% of the energy needed for new steel production.

B. Waste Reduction

By compacting and preparing scrap metal for recycling, balers divert enormous quantities of metallic waste from landfills. This reduces the burden on waste disposal sites, prevents potential soil and water contamination from decomposing metals, and frees up valuable land.

C. Carbon Footprint Reduction

The energy savings achieved through metal recycling directly translate into a reduction in greenhouse gas emissions. Less energy consumption means fewer fossil fuels are burned, thereby lowering the overall carbon footprint associated with metal production. Furthermore, avoiding the mining and primary processing of ores also reduces emissions from these activities.

D. Promoting Sustainable Practices

The presence and efficient operation of scrap metal balers encourage and facilitate broader sustainable practices within industries and communities. They make metal recycling more economically viable and logistically feasible, thus promoting a stronger recycling culture and contributing to a greener industrial landscape.

VIII. Conclusion

The scrap metal baler, though often operating behind the scenes, is an indispensable machine in the modern world. Its ability to transform bulky, unmanageable metal waste into compact, valuable bales underpins the efficiency and profitability of the metal recycling industry. From optimizing space and enhancing safety to significantly reducing transportation costs and increasing material value, the benefits it offers are profound and far-reaching.

Looking ahead, the role of scrap metal balers is only set to grow. Innovations in baler technology, such as increased automation, smarter control systems, and improved energy efficiency, will further enhance their capabilities. As global demand for sustainable solutions continues to escalate, and as industries strive for greater resource efficiency, the scrap metal baler will remain at the forefront, a crucial tool in our collective effort to build a more circular and environmentally responsible future. Its continued evolution will be key to unlocking even greater potential in the vital journey of metal recycling.