With the continuous development of industrialization, the recycling and reuse of scrap metals has become an important measure to save energy, reduce emissions and reduce environmental pollution. Scrap metal chips, as a widely existing industrial by-product, often face problems such as large space occupation, high recycling difficulty and low recycling rate in traditional treatment methods. The emergence of scrap metal chips briquetting machine provides a solution to this problem. By compressing scrap metal chips into dense blocks, it not only saves a lot of storage space, but also greatly improves the recycling value of metals.

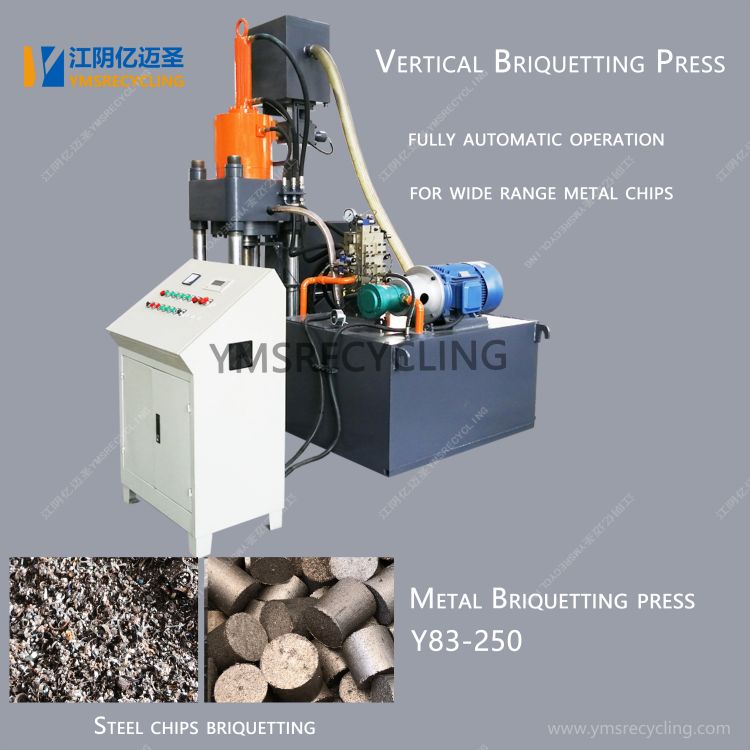

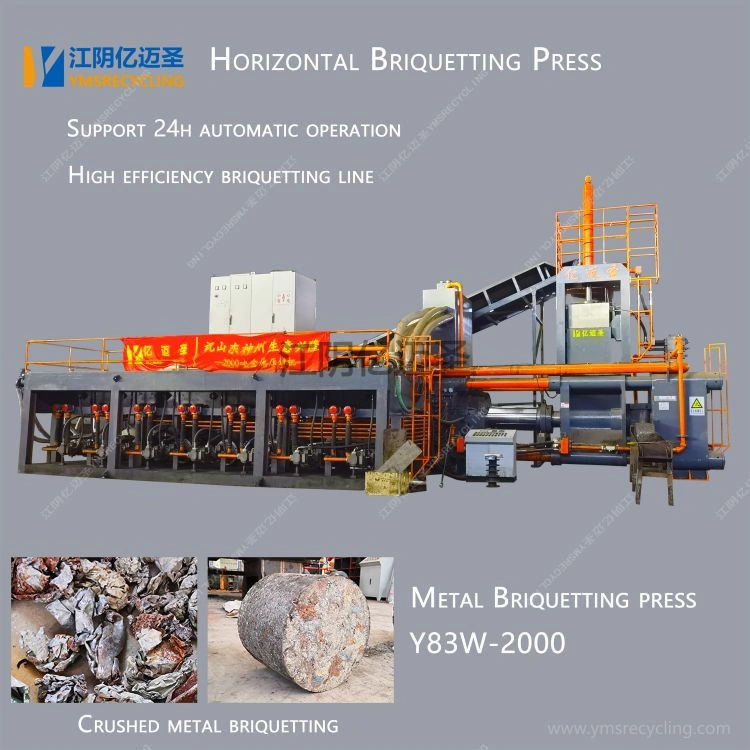

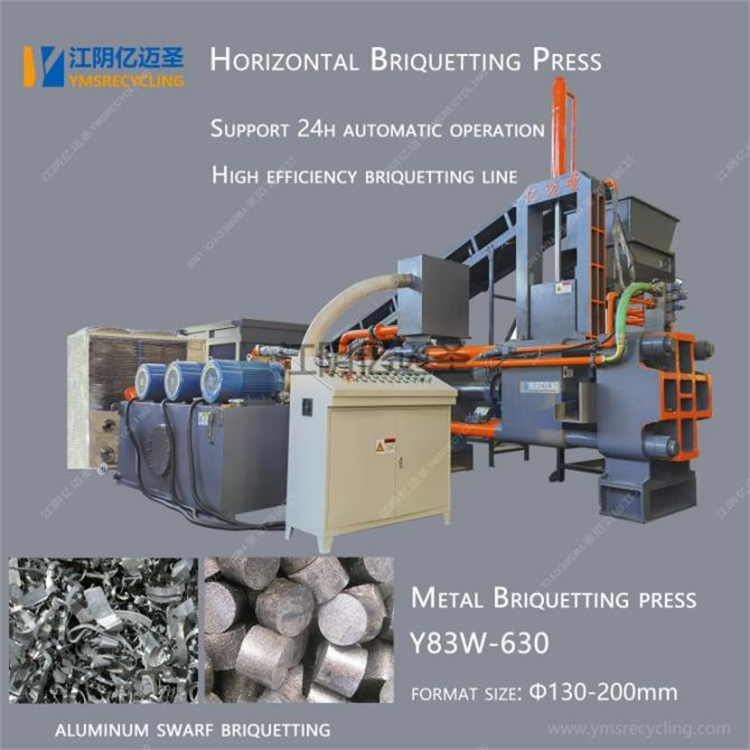

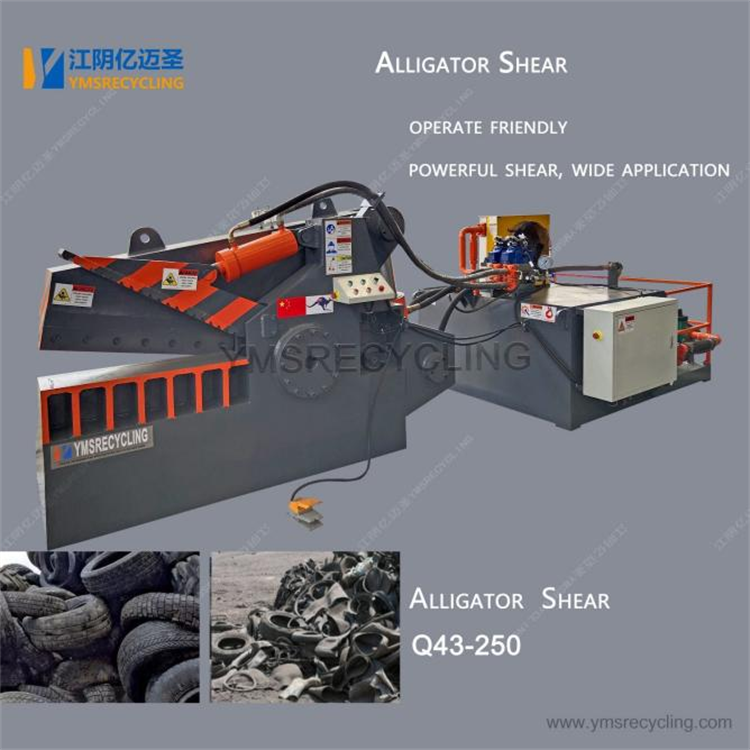

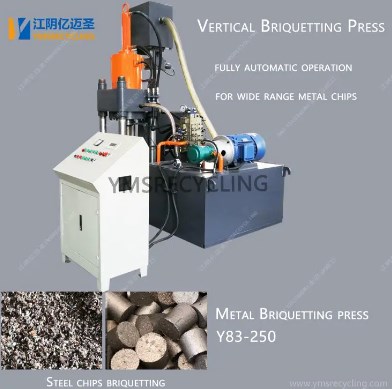

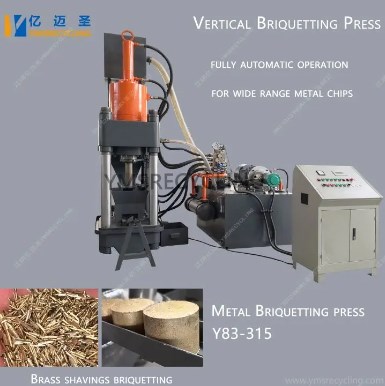

Scrap metal chips briquetting machine is a kind of equipment specially used for processing industrial waste such as metal chips, cutting fluids and metal scraps. It compresses scrap metal chips into blocks of a certain shape and density through strong pressure, making it easy to store, transport and reprocess. These compressed metal blocks have a high recycling value and can usually be smelted again to make new products.

Working principle of scrap metal chips briquetting machine

The working principle of scrap metal chips briquetting machine is relatively simple. It mainly provides high pressure through the hydraulic system to compress metal chips into blocks. The specific steps are as follows:

Metal chips collection: Collect metal chips to the feed port of the briquetting machine, which can be cutting chips, aluminum chips, copper chips, etc.

Compression process: The hydraulic system in the equipment provides strong pressure to quickly compress the metal chips into blocks.

Forming and discharge: The compressed metal blocks will be extruded and formed to complete the briquetting process.

Through this series of actions, the scrap metal chips are effectively compressed and shaped, which greatly reduces their volume and lays the foundation for further processing and utilization.

Advantages of scrap metal chips briquetting machine

Increase recovery rate

Because the briquetting machine can compress metal chips into dense blocks, the recovery rate of metal is greatly improved. By smelting these metal blocks, high-quality metal raw materials can be obtained, reducing resource waste.

Reduce transportation costs

The traditional method of handling metal chips requires a lot of storage space and has high transportation costs. After the scrap metal chips are processed by the briquetting machine, the volume can be reduced, making storage and transportation more convenient and economical.

Energy saving and environmental protection

The use of briquetting machines not only saves resources, but also reduces the scattering of metal chips in the natural environment. The compressed metal blocks can be efficiently reused, avoiding a large amount of waste from polluting the environment.

Improve production efficiency

The briquetting machine can continuously and efficiently process metal chips, significantly improving the operating efficiency of the production line. Especially for some large-scale production plants, the scrap metal chips briquetting machine can significantly reduce manual processing time and labor costs.

Application areas of scrap metal chips briquetting machine

Scrap metal chips briquetting machine is widely used in many industries, mainly including:

Metal processing industry: A large amount of metal chips will be generated in lathes, milling machines, grinders and other equipment. The scrap metal chips briquetting machine can process these cutting wastes into blocks for easy transportation and recycling.

Casting industry: Aluminum chips, copper chips and other metal wastes will be generated during the casting process, and the briquetting machine can effectively process these wastes.

Scrap metal recycling industry: Scrap metal recycling companies can convert waste metal materials into reusable resources and increase recycling value by using scrap metal chips briquetting machines.

Factors to consider when choosing a scrap metal briquetting machine

Hydraulic pressure and compression efficiency

When choosing a scrap metal briquetting machine, you first need to pay attention to the pressure and compression efficiency of the hydraulic system. High pressure can ensure that the scrap metal briquettes are compressed into blocks in a short time, improving production efficiency.

Durability of equipment

Since the scrap metal briquetting machine operates under high-load working conditions for a long time, the durability of the equipment is crucial. Choosing equipment with high-quality wear-resistant materials can reduce equipment failures and downtime.

Adaptability

Different types of metal shavings, such as aluminum shavings, copper shavings, steel shavings, etc., may have different properties and treatment methods. Therefore, when purchasing, you need to consider the adaptability of the briquetting machine to ensure that it can handle various types of scrap metals.

Degree of automation

Most modern scrap metal briquetting machines have a high level of automation, which can realize automatic feeding, compression, discharging and other operations, reduce manual intervention and improve production efficiency.

As an important equipment to improve metal recycling and reduce environmental pollution, scrap metal briquetting machines have become an indispensable part of modern industry. With the continuous advancement of technology, the performance and efficiency of these equipment are also constantly improving. For enterprises that need to process a large amount of metal chips, investing in an efficient and durable scrap metal chips briquetting machine can not only effectively reduce costs, but also improve resource utilization, bringing higher economic and environmental benefits to the enterprise.