Amid the global wave of resource recycling, the scrap metal recycling industry is undergoing a transformation from extensive processing to refined processing. As a key piece of equipment in this process, scrap metal balers, through their technological iterations and application upgrades, directly impact the efficiency and value of the recycling industry chain. This mechanical device, specifically designed to compress loose scrap metal materials, not only solves the problem of wasted space in scrap metal storage and transportation, but also, through standardized processing, provides a stable raw material form for subsequent smelting and recycling, becoming a crucial link between front-end recycling and back-end processing.

Analyzing the Core Structure and Operating Logic of a Scrap Metal Baler

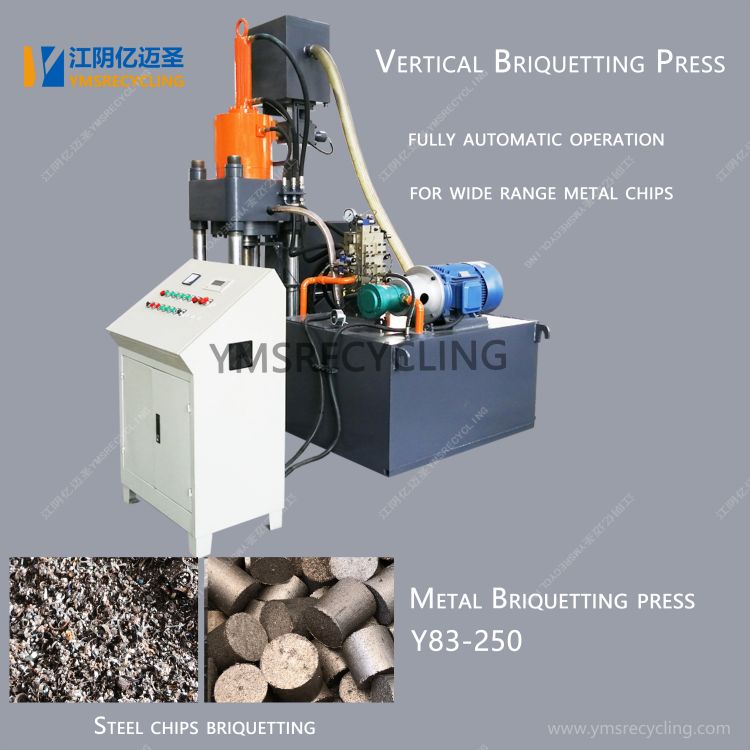

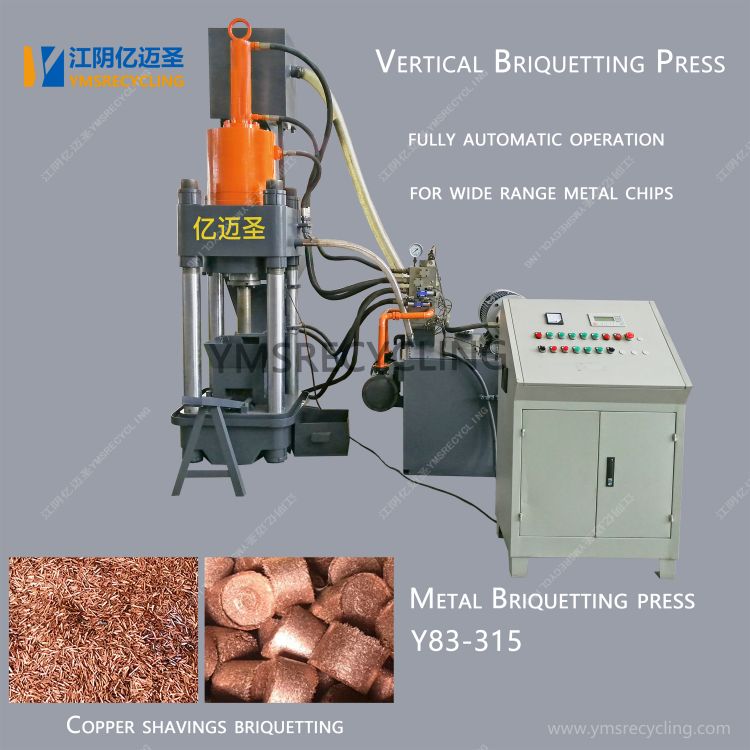

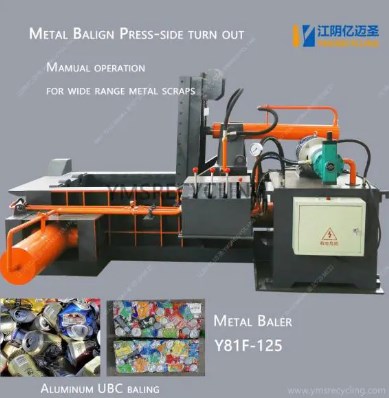

The efficient operation of a scrap metal baler relies on scientific structural design and a precise power transmission system. Its core structure typically consists of four major components: a feeder, a compression mechanism, a control system, and a discharge mechanism. These components work together to complete the entire process from material input to finished product output. The feeder receives scrap metal via a conveyor or manual feed port. Depending on the material's characteristics (e.g., thin, heavy, or mixed), the feed channel dimensions and guide structures are designed to ensure uniform material delivery to the compression zone.

The compression mechanism is the heart of the baler, consisting of a hydraulic cylinder, a compression push plate, and a compression chamber. When the material reaches the preset fill level, the hydraulic system drives the push plate to apply continuous pressure to the material, utilizing the metal's plasticity to densify it. The intensity and duration of this pressure are tailored to the metal's material. For highly ductile non-ferrous metals like aluminum and copper, pressure must be controlled to avoid excessive deformation that could affect subsequent sorting. For high-strength metals like steel, higher pressure is required to achieve the desired compression density.

The control system acts as the baler's "brain," coordinating the operations of various components through a programmable logic controller (PLC). The operator can set parameters such as compression pressure and hold time via a touchscreen interface, and the system automatically completes the cycle of feeding, compression, bundling (on some models), and discharging. Advanced control systems also feature fault diagnosis capabilities, enabling real-time monitoring of key indicators such as hydraulic oil temperature and pressure sensor status, reducing equipment failure rates.

Technological Evolution: From Hydraulic Drive to Intelligent Integration

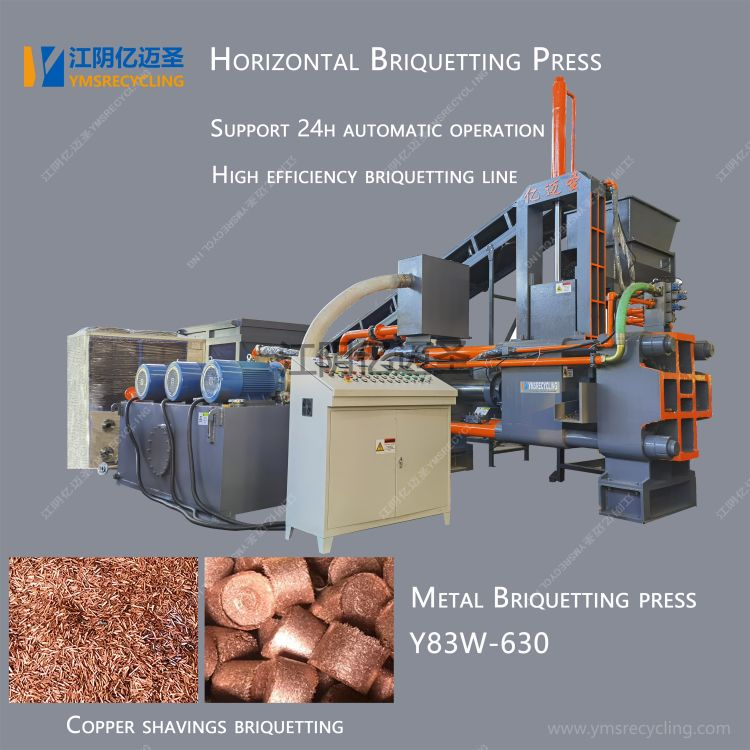

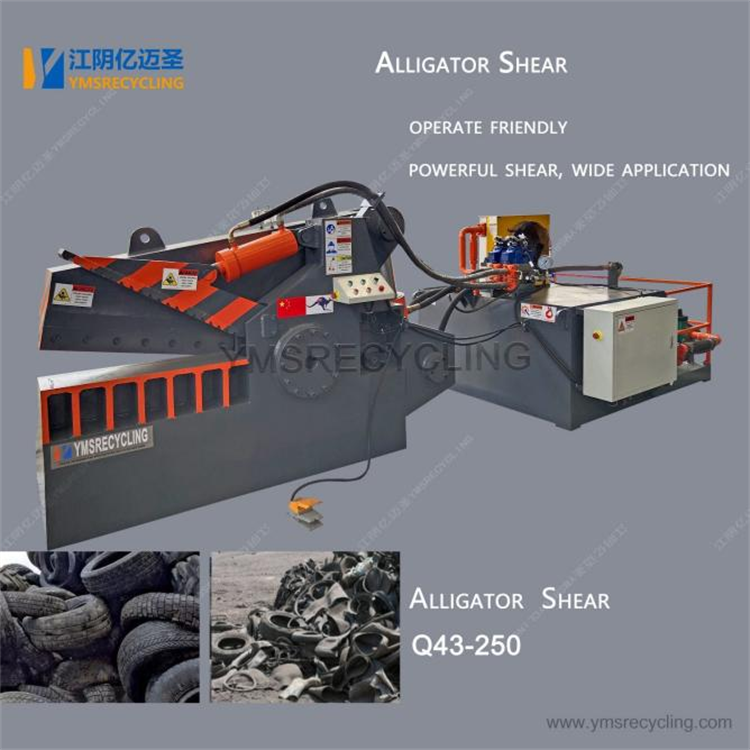

Early scrap metal balers primarily relied on mechanical transmission, resulting in limitations such as insufficient pressure and cumbersome operation, making them suitable only for processing small amounts of light and thin scrap metal. With the maturity of hydraulic technology, balers powered by hydraulic pumps have gradually become mainstream. These balers use hydraulic cylinders to convert fluid pressure into mechanical force, capable of achieving hundreds of tons of compression force, meeting the demands of handling heavy scrap metal such as steel plates and pipes. The stability of the hydraulic system directly determines the performance of the baler. Modern equipment often utilizes dual-pump converging technology, increasing flow during the rapid feeding phase and pressure during the compression phase, achieving a balanced balance between efficiency and power.

In recent years, intelligence has become a key development direction for scrap metal balers. Devices equipped with IoT modules can upload real-time operating data to cloud platforms, allowing managers to remotely monitor equipment status, energy consumption, and production progress via mobile phones or computers. Some high-end models are equipped with visual recognition systems that automatically distinguish between different types of scrap metal and adjust compression parameters to optimize baling results. Intelligent integration not only improves the efficiency of individual machines but also drives automation upgrades across the entire recycling plant, enabling unmanned operation throughout the entire process, from feeding, baling, to palletizing.

Basic maintenance of balers is also crucial in these applications. Regularly changing the hydraulic oil, inspecting seals, and cleaning filters can effectively extend the life of the equipment. Furthermore, the strapping method should be adjusted based on the material's characteristics. For sharp metal scraps, high-strength steel wire is used to prevent loosening; for lightweight materials like aluminum shavings, plastic strapping can be used to simplify handling. Proper use and maintenance will ensure that scrap metal balers continue to play a core role in resource recycling, driving the recycling industry towards efficiency, environmental protection, and intelligent development.