Under the background of rapid industrial development today, the recycling of metal resources has become an important issue that attaches equal importance to environmental protection and economic benefits. With the large-scale development of manufacturing and heavy industry, a large amount of metal waste is generated during the production process, which not only occupies a large amount of storage space, but also poses a potential threat to the environment. In order to effectively manage and reuse these scrap metal resources, Hydarulic scrap metal baler machine came into being and became an indispensable key equipment in the scrap metal recycling and processing industry.

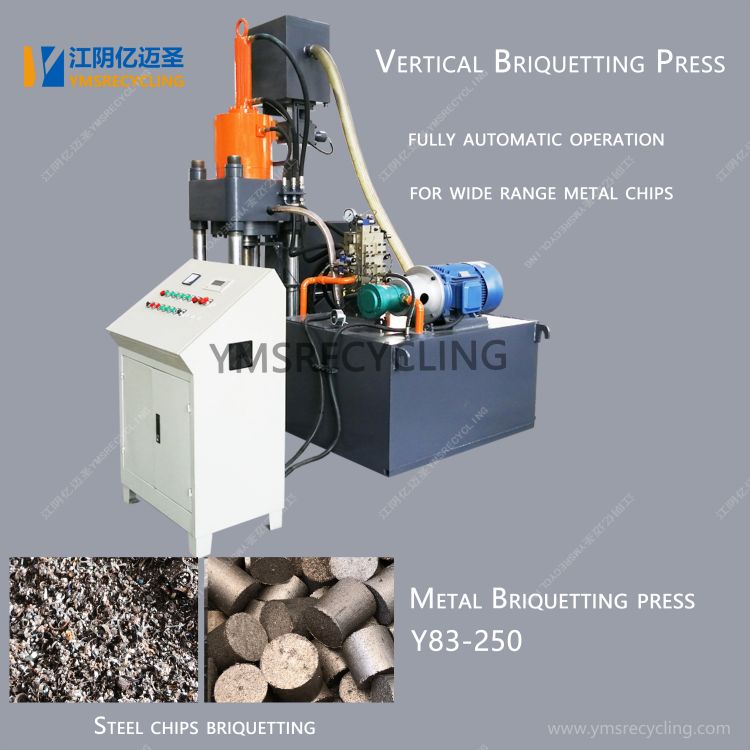

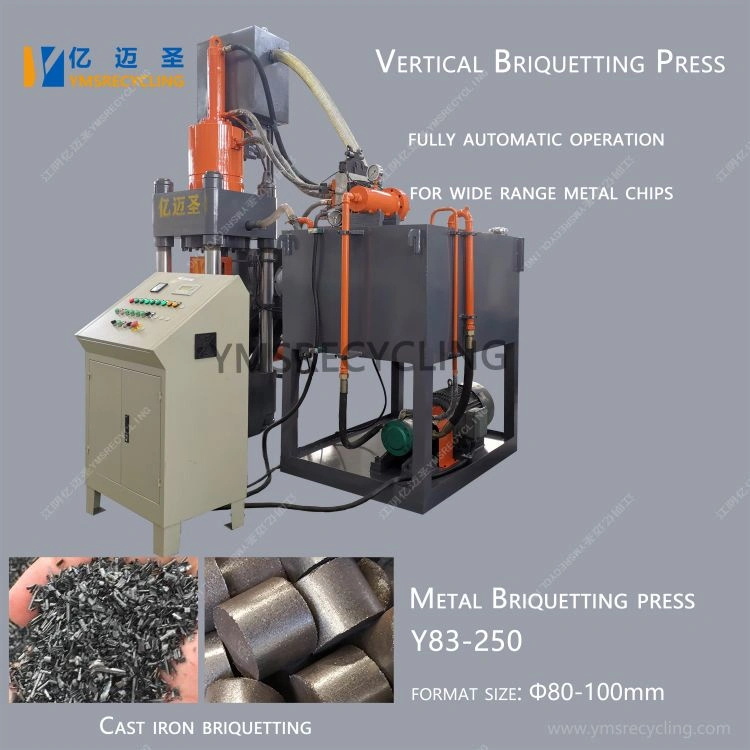

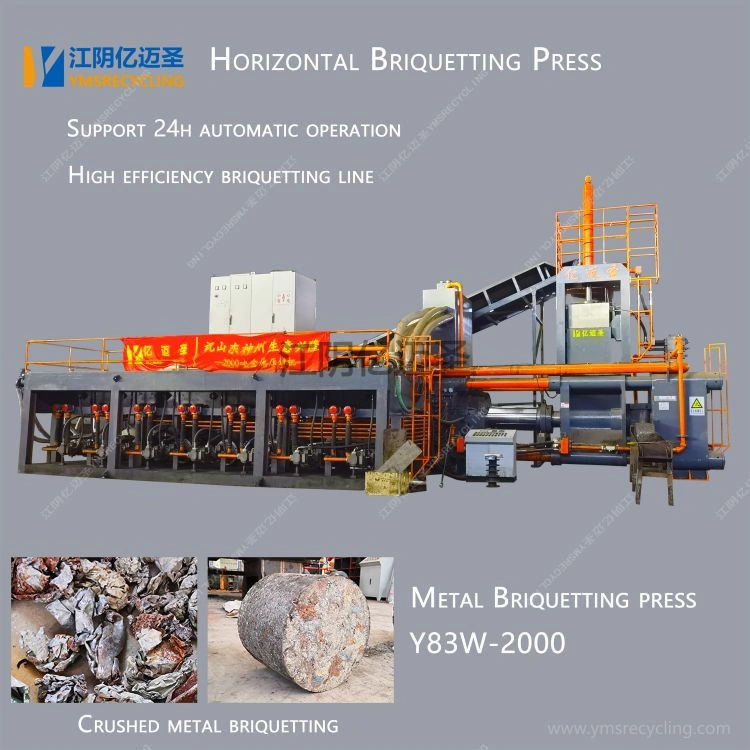

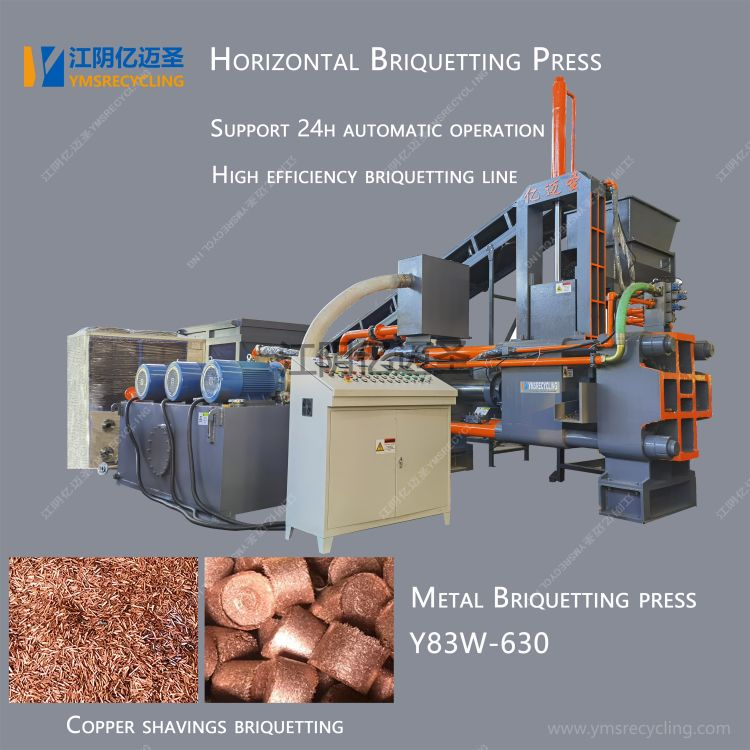

Hydarulic scrap metal baler machine is a device that uses a hydraulic system to apply huge pressure to compress loose scrap metal into compact blocks of regular shapes. Through an efficient compression mechanism, the equipment can significantly reduce the volume of scrap metal, increase stacking density, and facilitate transportation and reprocessing. This not only effectively saves storage space, but also greatly reduces transportation costs and improves the economic benefits of metal recycling.

As the core technology of the whole machine, the hydraulic system determines the working efficiency and compression capacity of the equipment. Modern hydraulic balers usually adopt fully automatic or semi-automatic control systems, combined with high-performance hydraulic pumps and cylinders, and can complete the baling of large amounts of metal scrap in a short time. Compared with traditional mechanical compression equipment, hydraulic systems have a more stable operating state, higher pressure output and less mechanical wear, which significantly improves the service life and operating stability of the equipment.

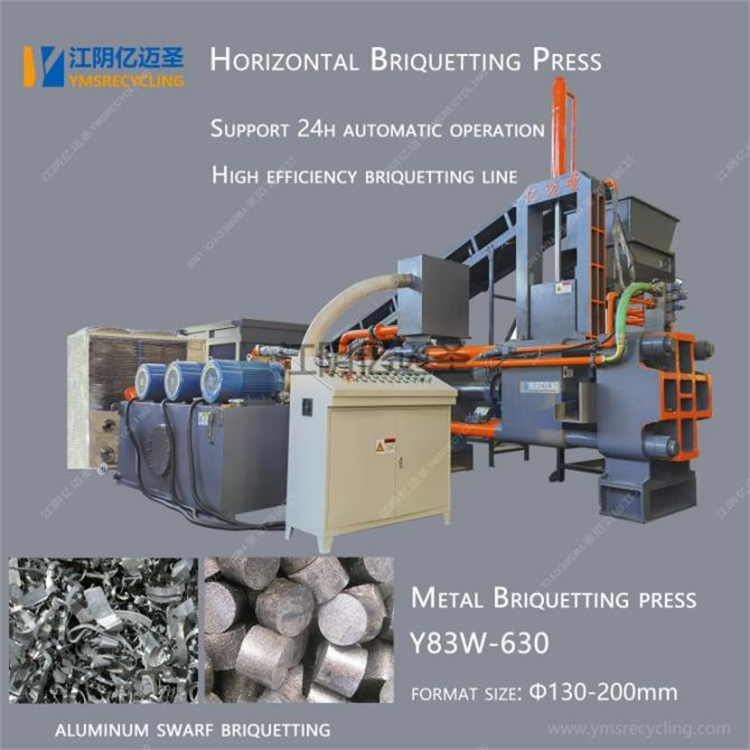

From the perspective of structural design, hydraulic scrap metal balers are usually welded with heavy steel plates, with strong compression resistance and wear resistance, and are suitable for various types of metal scrap, such as scrap steel, aluminum, copper wire, stainless steel sheets and even car shells. According to different compression methods, common ones are horizontal and vertical structures, and there are also "three-way compression" type equipment, which can efficiently compact metal from multiple directions at the same time, adapting to different operating scenarios and needs.

Hydarulic scrap metal baler machine is widely used in metal recycling stations, renewable resource processing plants, steel smelting enterprises and waste recycling departments of large manufacturing enterprises. It not only simplifies the waste treatment process, but also plays a positive role in environmental protection. After packaging, metal scrap can enter the smelting and remanufacturing links more efficiently, avoiding resource waste, reducing environmental pollution, and helping to achieve the development goal of circular economy.

With the advancement of science and technology, intelligence and automation have become important development trends of hydraulic scrap metal balers. New equipment is gradually equipped with PLC control systems, remote operation functions and intelligent detection sensors, which not only improves the convenience and safety of operation, but also monitors the equipment status and packaging quality in real time to achieve a higher level of process control. Some high-end models even have automatic feeding, automatic packaging and fault self-diagnosis functions, which greatly reduces the labor intensity of operators and improves production efficiency.

The popularization and application of hydraulic scrap metal balers is not only a powerful response to the problem of metal waste management in industrial production, but also an important practice to promote green and low-carbon development and build a resource-circulating society. Faced with increasingly severe environmental challenges and resource shortages, this equipment undoubtedly provides a sustainable, efficient and controllable solution.