Amid the rapid development of modern industry, the amount of scrap metal continues to grow, and resource recovery and reuse have become a highly sought-after global issue. As a crucial component of the circular economy, scrap metal recycling machines are continuously innovating technology, improving processing efficiency, and promoting the efficient reuse of waste resources. They are not only crucial for environmental protection but also a key link in the raw material supply chain for metal smelting and manufacturing.

Core Equipment for Scrap Metal Processing

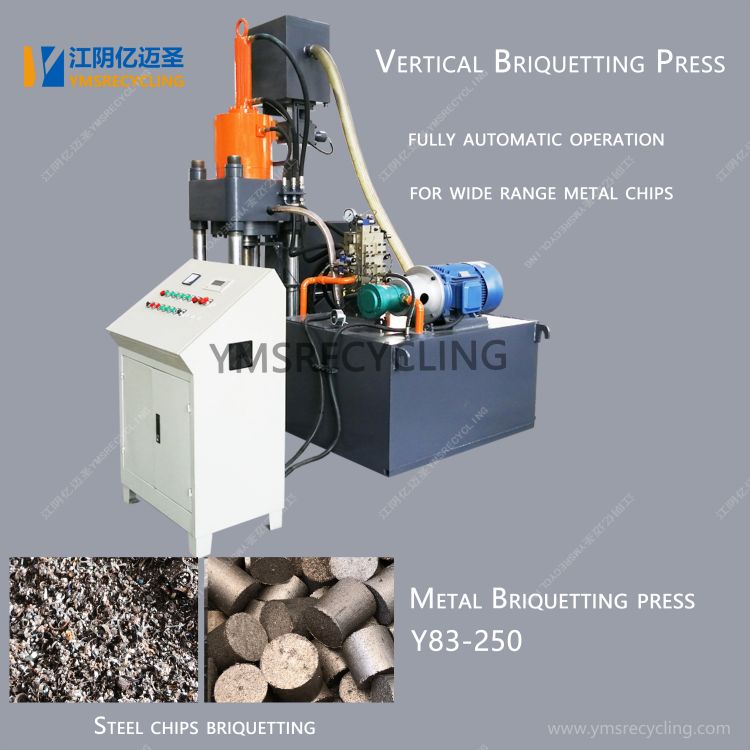

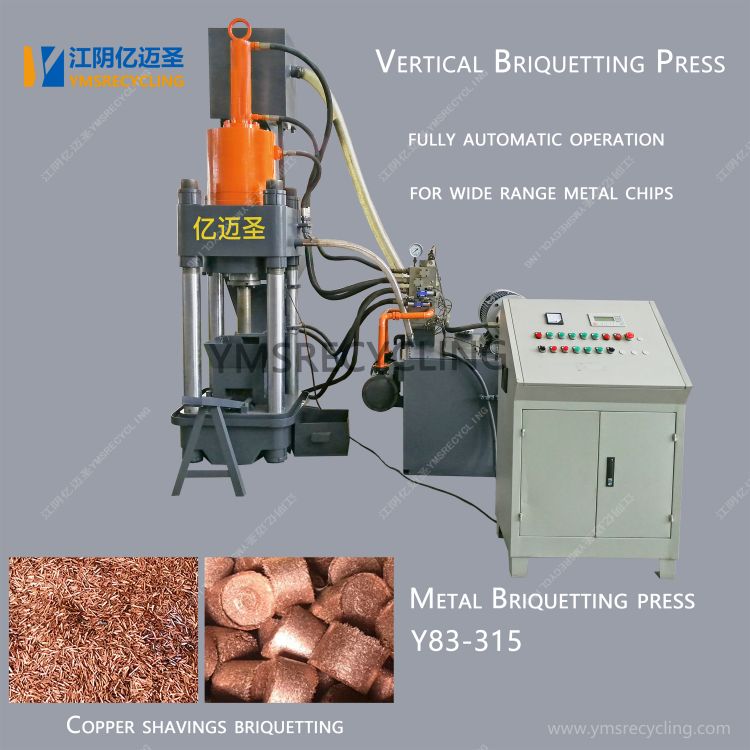

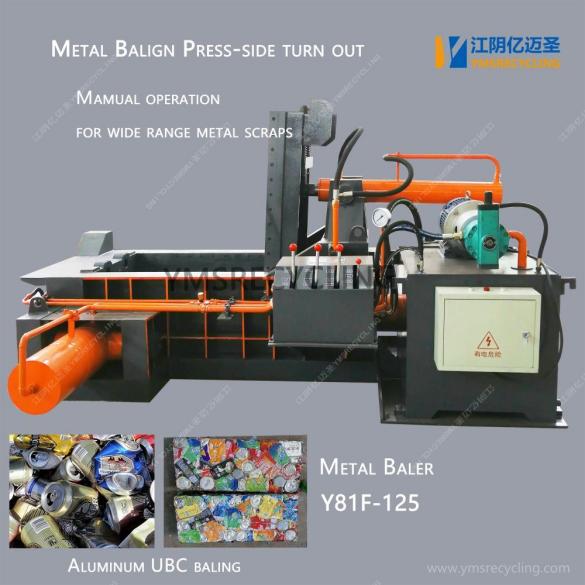

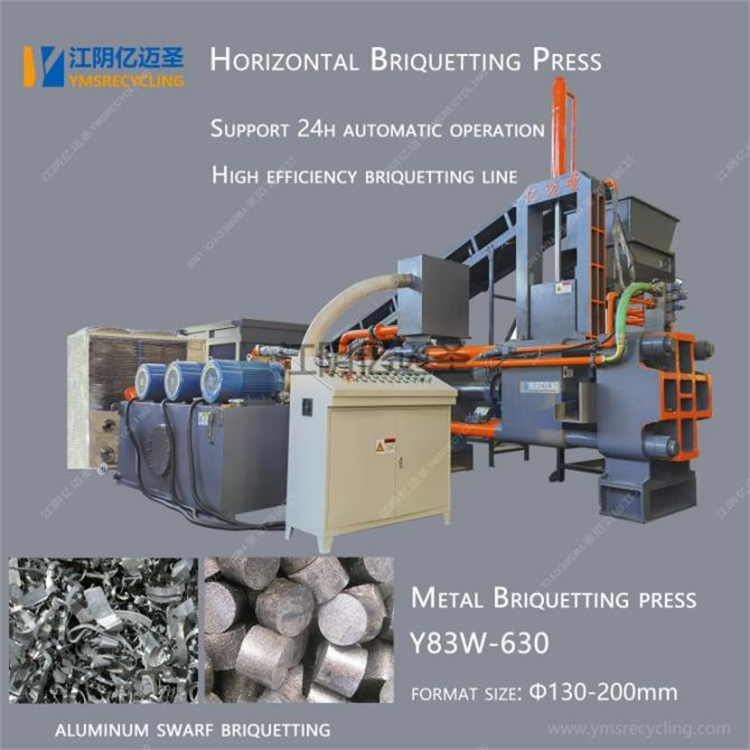

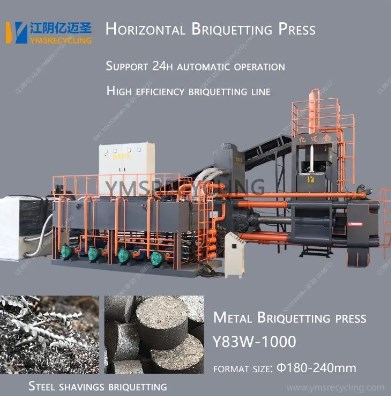

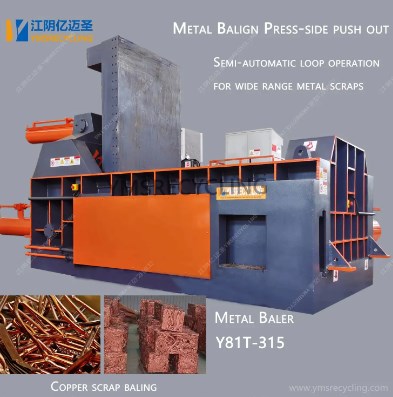

Scrap metal recycling machines are specialized equipment used for crushing, shearing, compressing, and sorting various types of scrap metal. Their primary goal is to transform large, complex scrap metal into high-quality raw materials that are easily stored, transported, and processed. Whether it's steel, aluminum, copper, stainless steel, or alloys, various types of machinery can be used for pre-processing, effectively addressing the difficulties and inefficiencies of manual sorting.

In industrial applications, scrap metal recycling machines typically include multiple core modules, such as a crusher, shearer, briquette press, and sorting system. These machines often integrate automated control systems, enabling customized operations based on different metal materials and forms, maximizing resource recovery rates, reducing energy consumption, and adapting to the needs of sustainable industrial development.

Technological Leaps in Intelligence and Automation

In recent years, with the advancement of artificial intelligence and automation technologies, scrap metal recycling machinery has been experiencing a wave of intelligent upgrades. Traditional mechanical control has been gradually replaced by programmable logic controllers (PLCs), the Industrial Internet of Things (IIoT), and visual recognition systems, making equipment operation more precise and efficient. During the identification and sorting stages, sensor-based intelligent sorting technology can effectively distinguish between different metal materials, reducing manual intervention and improving recycling purity.

Remote monitoring and predictive maintenance technologies are also widely used in scrap metal recycling machinery. Equipment operating status can be uploaded to a management platform in real time, enabling early warning mechanisms through big data analysis to avoid unexpected downtime and improve overall equipment stability and service life. This technological advancement not only reduces operating costs but also significantly enhances the reliability and intelligence of industrial waste processing.

A win-win model of environmental benefits and economic returns

From a resource and environmental perspective, the use of scrap metal recycling machinery effectively reduces dependence on raw ore resources and mitigates the environmental pollution caused by mineral mining and smelting. Especially within the strategic goals of carbon neutrality and green manufacturing, metal recycling can significantly reduce carbon emissions and water consumption, enhancing the sustainability of the entire industrial chain.

From an economic perspective, using scrap metal recycling machinery to reprocess metal materials not only saves significant raw material procurement costs but also generates substantial revenue from the sale of recycled metal products. For companies with large scrap production volumes, deploying efficient recycling machinery systems has become a crucial means of reducing costs, increasing efficiency, and achieving a green transformation.

Continuous Expansion of Applications

Scrap metal recycling machinery has a wide range of applications, from urban building dismantling and automobile scrapping to heavy industries such as shipbuilding and machinery manufacturing, and further refined sectors such as electrical appliance, home appliance, and electronic waste recycling. Demand for the reuse of metal resources is growing across various industrial chains. This is driving the continuous evolution of related equipment technology, gradually moving towards high efficiency, low energy consumption, intelligence, and miniaturization.

Especially with the retirement of new energy vehicles, urban renewal, and industrial upgrading, large quantities of scrap metal with complex structures and diverse compositions are flooding the market, placing higher demands on the process adaptability of recycling machinery. The new generation of equipment generally adopts a modular design structure, supporting mixed processing of multiple metal types and flexibly addressing complex application scenarios. Furthermore, AI algorithms optimize processing paths, achieving a balance between efficiency and precision, meeting the demands of the refined development of modern industry.

Future Trends in Scrap Metal Recycling Machinery

Looking ahead, scrap metal recycling machinery will continue to develop, driven by both environmental protection policies and expanding market demand. On the one hand, equipment manufacturers will continue to strengthen research in materials engineering and automated control to enhance equipment durability and processing adaptability. On the other hand, digital transformation will permeate equipment lifecycle management, including online monitoring, intelligent scheduling, and energy efficiency analysis, forming a closed-loop management system.

Scrap metal recycling machines are playing an increasingly prominent role in the current industrial system. They serve not only as a bridge for resource recycling but also as a key driver of sustainable development. In the era of green and intelligent manufacturing, only by continuously promoting technological upgrades and deeply integrating environmental protection concepts can we achieve truly high-quality industrial development in a future where resource constraints and environmental pressures coexist. With the powerful functions of scrap metal recycling machinery and the support of continuously evolving technologies, the vision of a green earth will no longer be far away.