In today's manufacturing industry, especially in metalworking, waste disposal has become a significant challenge. As companies strive to reduce costs and meet environmental regulations, Aluminum Shavings Briquetting Machines have emerged as a highly effective solution. These machines not only streamline waste management but also reduce disposal costs significantly. This article explores how an Aluminum Shavings Briquetting Machine can help companies manage their waste more efficiently, focusing on its benefits, investment analysis, and maintenance considerations.

1. What is an Aluminum Shavings Briquetting Machine?

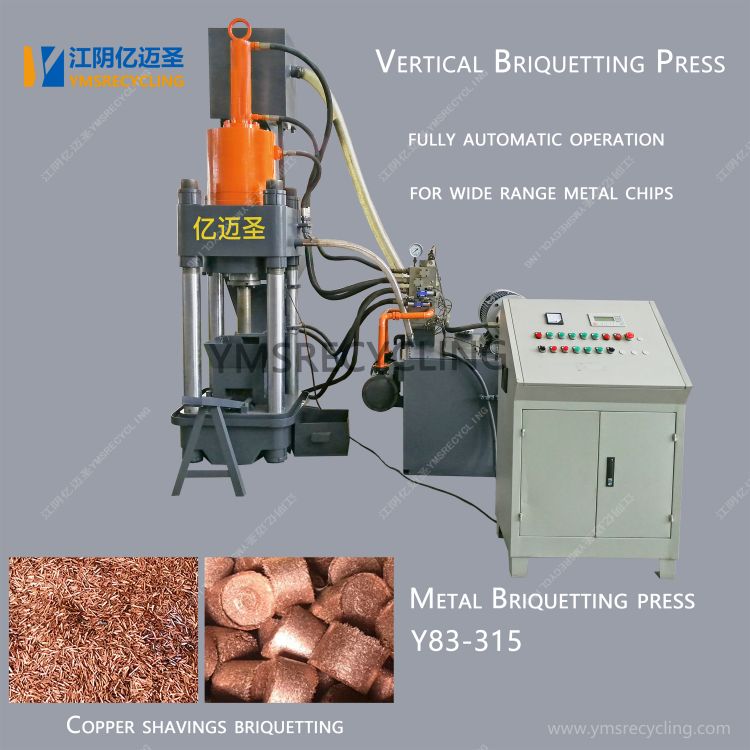

An Aluminum Shavings Briquetting Machine is a specialized piece of equipment designed to compress metal shavings, primarily aluminum, into dense briquettes. These briquettes are easier to store, transport, and sell compared to loose shavings.

Types of Aluminum Shavings Briquetting Machines

- Small-scale Briquetting Machines: Ideal for smaller businesses with limited production capacity.

- Large-scale Briquetting Machines: Designed for high-output operations, suitable for large manufacturing plants.

The machine typically uses hydraulic or mechanical force to compact the aluminum shavings into uniform shapes, which can then be sold for recycling or reused in production.

2. The Current State and Challenges of Waste Disposal Costs

Waste disposal, especially for metal shavings, can be an expensive process for businesses. Traditional methods often involve transportation, storage, and disposal fees, which can add up quickly. Furthermore, strict environmental regulations require businesses to handle waste in a compliant and sustainable manner.

Challenges Faced in Traditional Waste Disposal

- High transportation costs due to the bulkiness of loose aluminum shavings.

- Storage issues, as companies need large spaces for storing non-compacted waste.

- Waste disposal fees and environmental fines for improper disposal methods.

On top of these, businesses must comply with growing environmental regulations, further increasing the overall cost of waste management. It’s clear that finding a more efficient solution can significantly reduce these overheads.

3. How an Aluminum Shavings Briquetting Machine Helps Reduce Waste Disposal Costs

An Aluminum Shavings Briquetting Machine is a game-changer for companies looking to reduce waste disposal costs. By converting loose aluminum shavings into compact briquettes, these machines provide several key advantages.

Key Advantages of Using an Aluminum Shavings Briquetting Machine

- Reduced Transportation Costs: Briquettes are more compact and take up less space, lowering transportation costs.

- Reduced Storage Requirements: With their compact size, briquettes require less storage space, reducing overhead costs.

- Increased Profitability from Recycling: The compressed aluminum briquettes are of higher value in recycling markets, allowing businesses to recover more money.

- Environmental Compliance: Briquetting aluminum waste supports eco-friendly recycling processes and helps businesses meet stricter environmental regulations.

Comparison: Traditional Waste Disposal vs. Briquetting

To better understand the impact of using a briquetting machine, here’s a comparison of traditional waste disposal methods versus using an Aluminum Shavings Briquetting Machine:

| Method | Pros | Cons |

|---|---|---|

| Traditional Disposal | Simple, no need for additional equipment. | High transportation and disposal fees, environmental impact. |

| Briquetting | Reduces transportation, storage, and disposal costs, improves recycling revenue. | Initial investment cost for the machine, maintenance costs. |

4. Investment Cost and ROI Analysis

Investing in an Aluminum Shavings Briquetting Machine comes with an initial cost, but the savings and potential revenue in the long term can make this a highly cost-effective solution.

Investment Breakdown

- Initial Purchase Cost: Depending on the size and capacity, the cost of these machines can range from $10,000 to $50,000.

- Maintenance Cost: Regular maintenance and parts replacement are typically low-cost but important to keep the machine running efficiently.

Long-Term Savings and Return on Investment (ROI)

- Reduced Waste Disposal Costs: By reducing the volume of waste, companies save on disposal and transport costs.

- Increased Revenue from Recycling: The compressed briquettes are easier to sell to recycling centers, often at a higher price.

- Payback Period: Most businesses see a return on their investment within 1-3 years, depending on their production volume and recycling output.

5. Maintenance and Care for Aluminum Shavings Briquetting Machines

Proper maintenance ensures the longevity and efficiency of an Aluminum Shavings Briquetting Machine. Routine inspections and upkeep can prevent costly repairs and extend the life of the machine.

Maintenance Considerations

- Routine Checks: Regularly check the hydraulic system, belts, and compacting mechanism.

- Lubrication: Keep the machine well-lubricated to prevent friction-related wear and tear.

- Cleaning: Regular cleaning of the machine to avoid blockages and ensure smooth operation.

Effect of Proper Maintenance

By maintaining the Aluminum Shavings Briquetting Machine properly, companies can avoid breakdowns, ensure consistent operation, and reduce downtime, ultimately lowering operational costs.

6. Applications of Aluminum Shavings Briquetting Machines in Different Industries

Aluminum Shavings Briquetting Machines have diverse applications across various industries. Below are some examples of how these machines are beneficial in different sectors:

- Small Businesses: For small-scale manufacturers, these machines help optimize waste disposal and generate extra income from recycling.

- Large-Scale Manufacturers: Larger manufacturers benefit from high-output briquetting machines that increase production efficiency and reduce operational waste.

- Recycling and Environmental Goals: Companies focused on reducing their environmental footprint can meet regulatory standards and benefit from the ecological advantages of briquetting aluminum waste.

7. Real-World Examples and Success Stories

Several businesses have already adopted Aluminum Shavings Briquetting Machines and seen impressive results. These case studies highlight how the technology has improved waste management and saved costs.

Case Study 1: Small Business Waste Management

A small aluminum machining company invested in a briquetting machine and reduced their waste disposal costs by 30%. The company also saw an increase in profits from selling the compacted aluminum briquettes to local recyclers.

Case Study 2: Large-Scale Manufacturer

A large automotive parts manufacturer switched to briquetting their aluminum shavings, which led to a 20% reduction in waste management costs and a more streamlined recycling process.

Conclusion

In conclusion, an Aluminum Shavings Briquetting Machine is an invaluable tool for reducing waste disposal costs in aluminum processing. By investing in this technology, businesses can streamline their operations, increase recycling profits, and contribute to a more sustainable future.

FAQs

- What is the primary benefit of an Aluminum Shavings Briquetting Machine? - It helps reduce waste disposal costs by compacting aluminum shavings into recyclable briquettes, lowering transport and disposal fees.

- How does an Aluminum Shavings Briquetting Machine work? - The machine compresses loose aluminum shavings into dense briquettes that are easier to store, transport, and sell for recycling.

- What is the ROI of an Aluminum Shavings Briquetting Machine? - The ROI typically occurs within 1-3 years, depending on the scale of operation and volume of recyclable material processed.

- Are Aluminum Shavings Briquetting Machines suitable for small businesses? - Yes, there are compact models designed for small businesses that help reduce waste disposal costs and increase recycling revenue.

- How often do Aluminum Shavings Briquetting Machines require maintenance? - Regular maintenance includes checking the hydraulic system, lubricating moving parts, and cleaning the machine to ensure smooth operation.