The scrap metal chips briquetting machine plays a vital role in modern metal recycling, offering both waste management solutions and enhanced recycling efficiency. In this article, we will explore how this machinery helps in streamlining metal recycling processes, improving waste management, and boosting operational efficiency. We will also delve into key considerations when selecting the right machine for your business needs.

Overview of Scrap Metal Chips Briquetting Machines

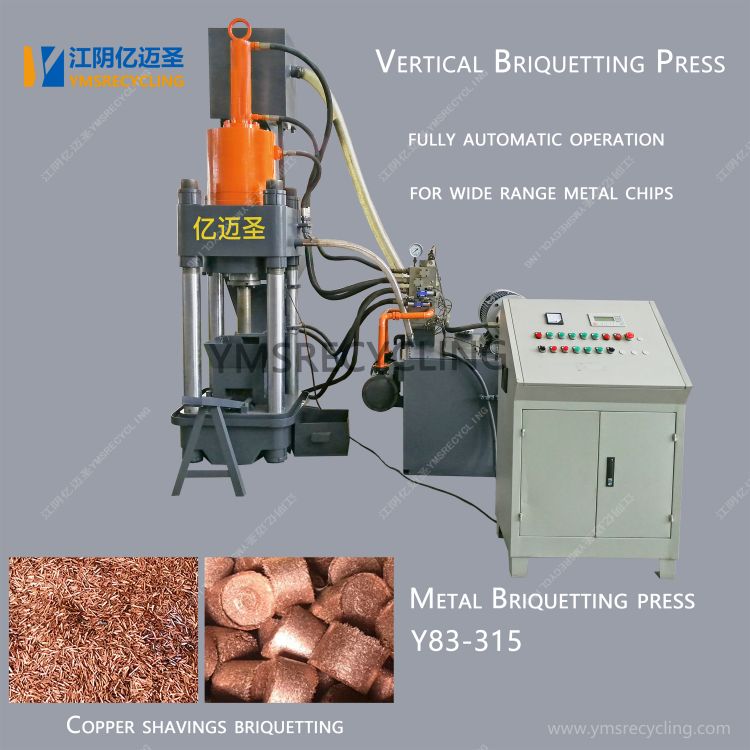

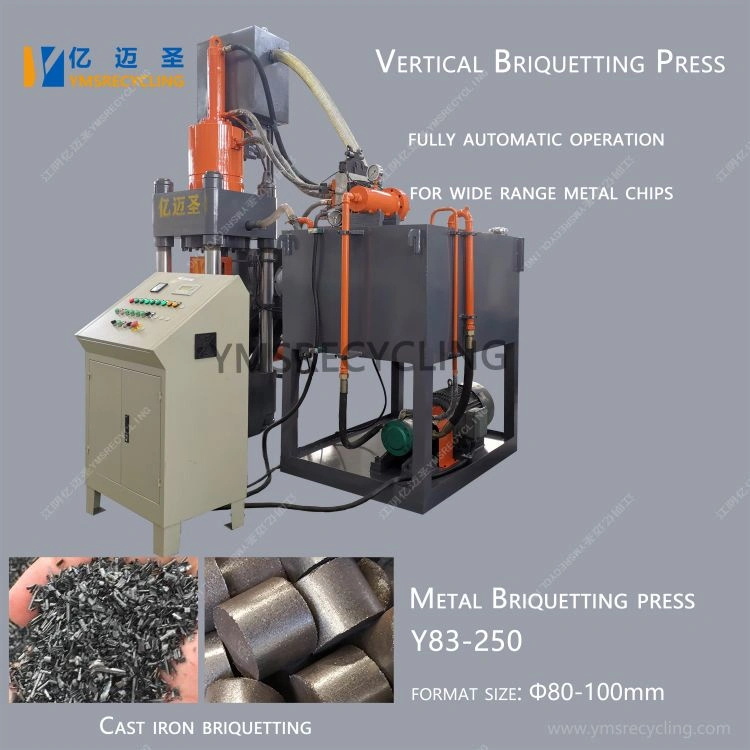

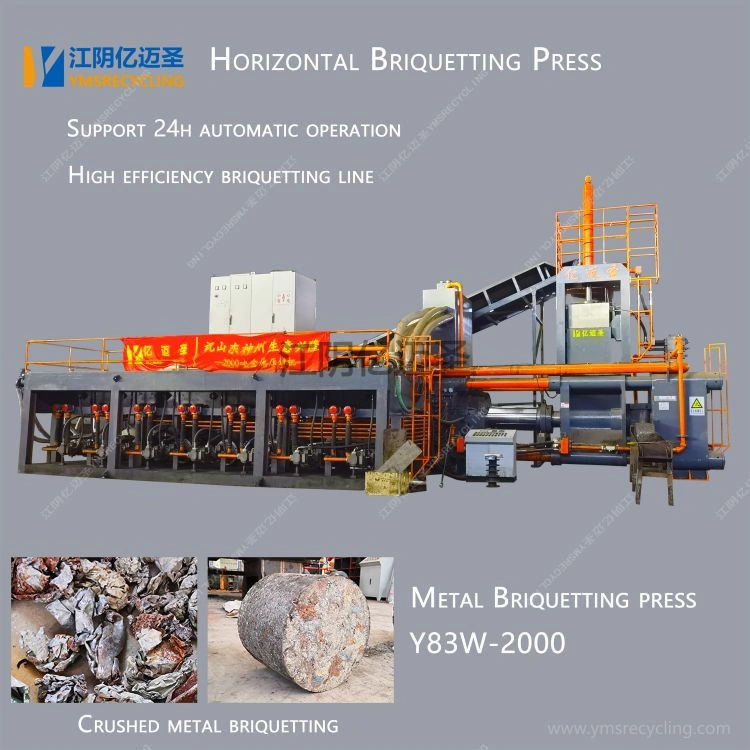

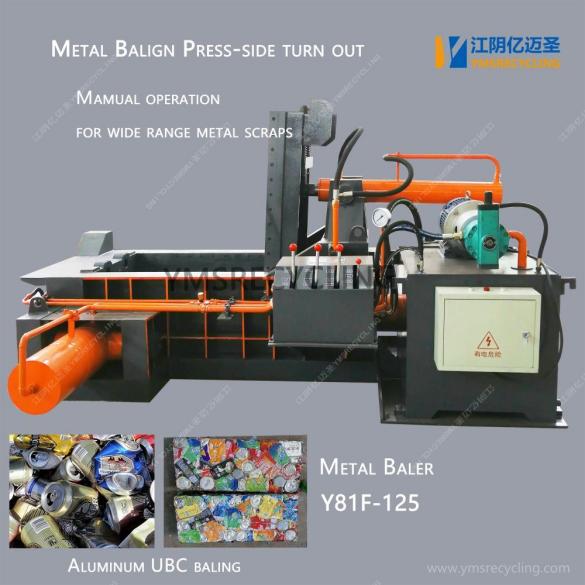

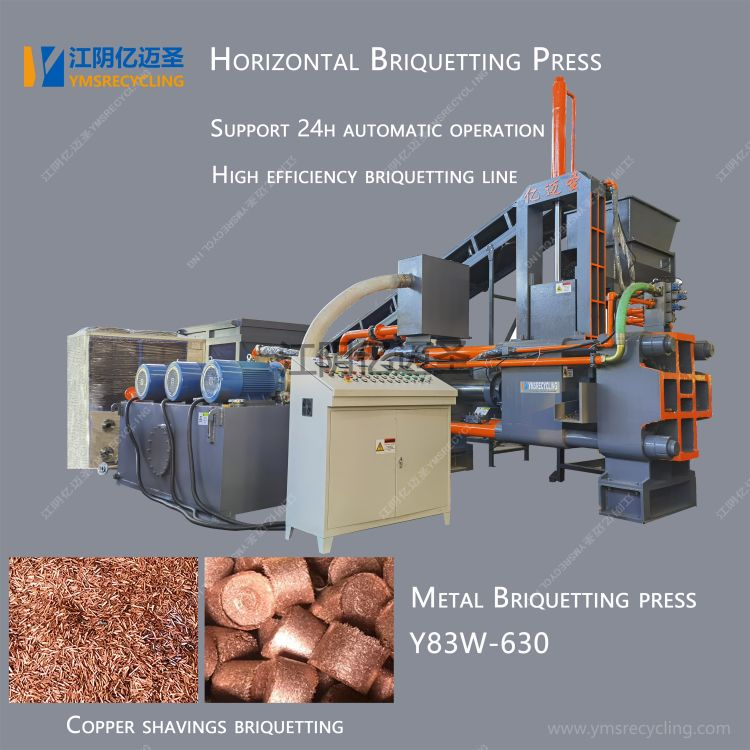

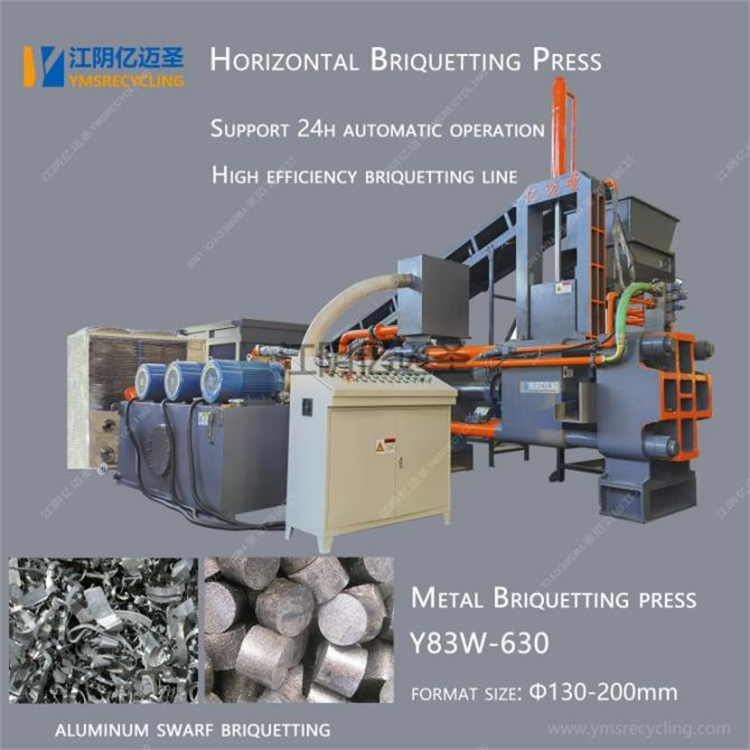

A scrap metal chips briquetting machine is designed to compact metal chips, filings, and other small pieces of metal into solid, uniform briquettes. These briquettes are easier to handle, store, and transport, which leads to greater efficiency in the recycling process. The machine typically uses hydraulic or mechanical pressure to compact the metal scrap into a dense form.

How it Works

- The metal chips are fed into the machine’s hopper.

- They are then compressed under high pressure to form compact briquettes.

- The resulting briquettes can be reused in further production processes or sold as raw materials.

Advantages of Scrap Metal Chips Briquetting Machines for Waste Management

Waste management is a critical aspect of the recycling industry. By investing in a scrap metal chips briquetting machine, companies can significantly enhance their waste management processes.

Waste Reduction and Space Optimization

- Scrap metal chips briquetting machines help reduce the volume of metal scraps by up to 90%, making waste handling more efficient.

- By compressing metal chips into briquettes, companies save space, reduce the frequency of waste disposal, and ensure better organization of materials.

Environmental Impact

These machines also contribute to sustainability by improving recycling rates. Less waste is sent to landfills, and metal resources are effectively reused, which is beneficial for the environment.

| Benefit | Description |

| Waste Volume Reduction | Reduces metal scrap volume by up to 90%, optimizing storage and reducing disposal costs. |

| Space Efficiency | Creates compact briquettes, minimizing storage space requirements and improving warehouse organization. |

| Environmental Impact | Improves recycling rates and reduces landfill waste, contributing to environmental sustainability. |

How Scrap Metal Chips Briquetting Machines Improve Recycling Efficiency

Recycling efficiency is paramount in modern industrial processes. A scrap metal chips briquetting machine enhances recycling by facilitating the easy reuse of metal scrap.

Increased Recovery Rates

By compacting metal chips into uniform briquettes, these machines allow for better sorting, separation, and processing of scrap metals. As a result, companies experience higher recovery rates of valuable metals like aluminum, steel, and copper, which are then recycled into new products.

Improved Transportability

Compared to loose scrap, briquetted metal is much easier to transport. This allows companies to consolidate shipments, reduce transportation costs, and simplify logistics.

Choosing the Right Scrap Metal Chips Briquetting Machine for Your Business

Selecting the right scrap metal chips briquetting machine depends on the size of your operation and the types of metal you handle. Below we compare options based on business size.

For Small Businesses

- Small businesses typically require more compact and affordable machines. These machines are easy to maintain and do not take up much space in the workshop.

- It’s crucial to choose a machine that is both cost-effective and efficient for low to moderate volumes of scrap metal.

For Medium-Scale Industries

- Medium-scale industries may require more robust machines capable of handling larger quantities of scrap metal.

- These machines should offer greater throughput while still being affordable for mid-range operations.

| Business Size | Machine Features |

| Small Business | Compact, affordable, low throughput, easy maintenance. |

| Medium-Scale Industry | Higher throughput, larger capacity, more advanced features. |

Maintenance Tips for Scrap Metal Chips Briquetting Machines

Regular maintenance is essential for ensuring the long-term performance and efficiency of your scrap metal chips briquetting machine.

Routine Inspections

- Check hydraulic fluid levels regularly to ensure smooth operation.

- Inspect the compression chamber for wear and tear to avoid breakdowns.

- Lubricate moving parts to minimize friction and prevent damage.

Common Maintenance Issues and Solutions

- Clogging of the feed hopper can occur if metal pieces are too large or not properly pre-processed.

- Periodic cleaning of the compression chamber can help avoid material buildup and improve efficiency.

The Future of Scrap Metal Chips Briquetting Machines

With advancements in technology, the future of scrap metal chips briquetting machines looks promising. New innovations focus on improving efficiency, reducing energy consumption, and integrating automation.

Technological Innovations

- Smart sensors and IoT capabilities to monitor machine performance in real-time.

- Energy-efficient systems to reduce operational costs and environmental impact.

Conclusion

In conclusion, a scrap metal chips briquetting machine is an invaluable tool for businesses looking to improve waste management and recycling efficiency. By investing in the right equipment, companies can streamline their operations, reduce costs, and contribute to a more sustainable future. Whether you're a small business or a medium-scale industrial operation, understanding the benefits, maintenance requirements, and future trends of this technology is essential for making an informed decision.

Frequently Asked Questions (FAQ)

1. What is the main purpose of a scrap metal chips briquetting machine?

The primary purpose of a scrap metal chips briquetting machine is to compact metal scrap into dense briquettes, which makes the material easier to store, transport, and recycle.

2. How does a briquetting machine improve waste management?

A briquetting machine reduces the volume of metal scrap by up to 90%, optimizing storage space and reducing disposal costs. It also facilitates the recycling process.

3. Can a scrap metal chips briquetting machine be used for all types of metal scrap?

Yes, most briquetting machines can handle a wide variety of metal scraps, including aluminum, steel, copper, and brass, although specific machines may be optimized for certain materials.

4. How do I maintain a scrap metal chips briquetting machine?

Regular maintenance includes checking hydraulic fluid levels, inspecting the compression chamber for wear, and lubricating moving parts to ensure smooth operation.

5. What are the benefits of investing in a briquetting machine for medium-scale industries?

For medium-scale industries, investing in a briquetting machine increases throughput, reduces transportation costs, and improves recycling efficiency, resulting in higher overall productivity.