With the continuous advancement of global industrialization, the recycling and utilization of scrap metal has become an important issue that cannot be ignored. Scrap metal baling machines, as one of the core equipment in the metal recycling industry, not only play a vital role in the recycling process of metal waste but also play an irreplaceable role in improving recycling efficiency and reducing labor costs. The hydraulic scrap metal baler machine, with its powerful compression capacity and efficient baling function, has become a highly favored mechanical equipment in the scrap metal processing industry.

Working Principle and Advantages of Hydraulic Scrap Metal Baler Machines

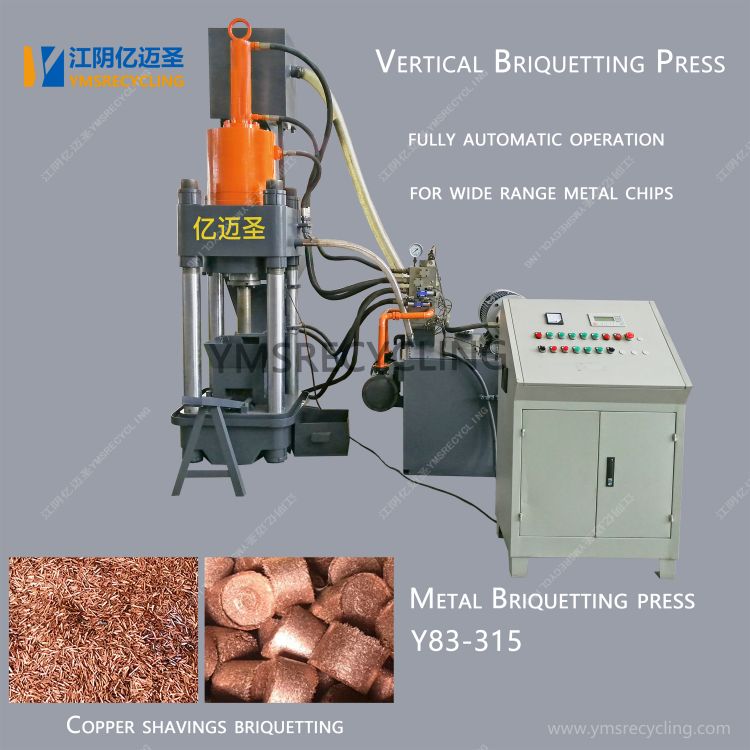

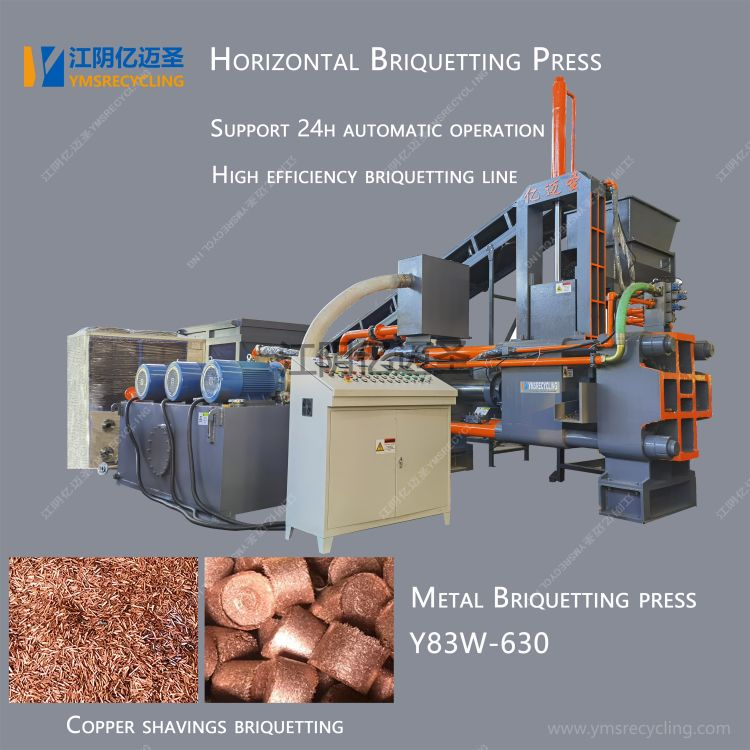

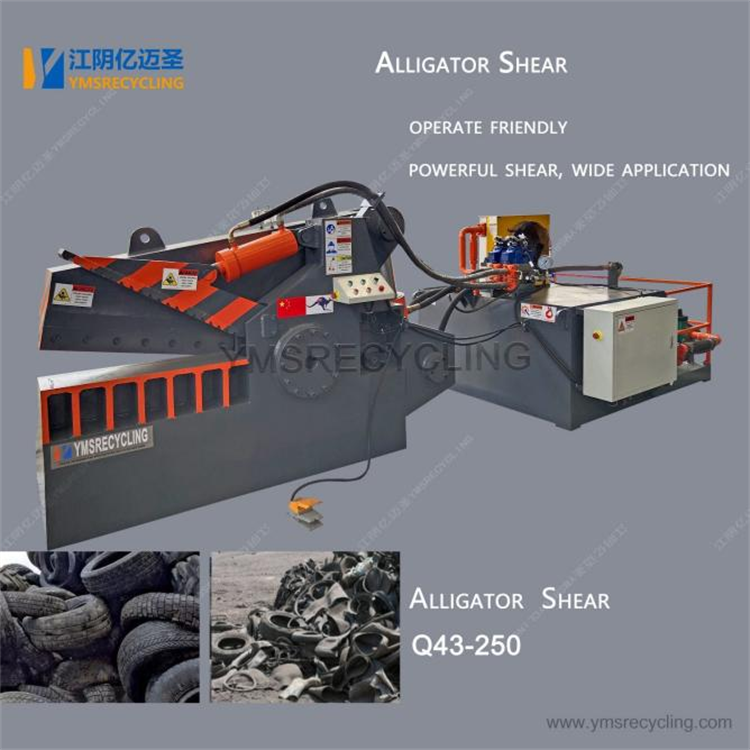

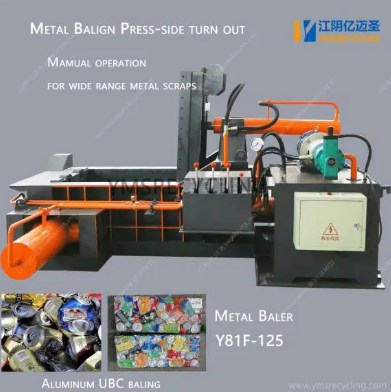

The hydraulic scrap metal baler machine uses a hydraulic drive system to compress scrap metal into compact blocks or square bales through hydraulic pressure, greatly reducing the volume of scrap metal and facilitating storage, transportation, and reuse. Its core components include a hydraulic system, compression chamber, and baling device, which can effectively bale various types of scrap metal—whether iron, aluminum, copper, or alloys—into a uniform shape. This mechanized operation mode not only improves the efficiency of scrap metal recycling but also greatly reduces manual labor intensity.

Compared with traditional manual dismantling or manual compression, the advantages of hydraulic scrap metal baling machines are very obvious. It can handle a large amount of scrap metal, greatly improving production efficiency; the hydraulic system can adjust the pressure according to the type and hardness of the scrap metal, making it highly adaptable and able to handle a variety of scrap metal materials; finally, due to the automated operation of the equipment, manual intervention is reduced, improving the safety and reliability of operation.

Scope of Application and Market Demand

Hydraulic scrap metal baling machines are suitable for a wide range of scrap metal types, covering almost all types of scrap metal. Whether it's metal residue from car dismantling or metal waste from construction waste, hydraulic scrap metal baling machines can handle it efficiently. Especially in the metallurgy, automobile dismantling, and scrap appliance recycling industries, hydraulic scrap metal baling machines are core equipment for achieving efficient resource recycling.

With the continuous improvement of environmental protection awareness, the market demand for the metal recycling industry is increasing. Especially against the backdrop of accelerated urbanization, the amount of various scrap metals recycled is constantly rising, and the demand for hydraulic scrap metal baling machines is also increasing accordingly. It can not only improve recycling efficiency and reduce environmental pollution but also bring higher economic benefits to enterprises. Therefore, hydraulic scrap metal baling machines have broad market prospects in the future.

Design and Innovation of Hydraulic Scrap Metal Balers

In the design process of hydraulic scrap metal balers, the optimization of the hydraulic system is crucial. Modern hydraulic systems, through precise control of hydraulic oil, enable the baler to provide accurate pressure output under different working conditions, which not only improves the efficiency of the equipment but also extends its service life. The energy-saving design of the hydraulic system also effectively controls the energy consumption of the hydraulic scrap metal baler, aligning with the modern trend of energy conservation and environmental protection.

The appearance design of balers is also becoming simpler and more intelligent. Many hydraulic scrap metal balers are equipped with intelligent control systems, making operation more convenient. They can monitor the equipment's operating status and provide fault warnings in real time, reducing equipment failure rates and improving operational safety. Through the intelligent control system, users can adjust the baling mode according to different types of scrap metal to achieve the best baling effect.

Maintenance and Upkeep of Hydraulic Scrap Metal Balers

To ensure the long-term stable operation of the hydraulic scrap metal baler, regular maintenance and upkeep are indispensable. The replacement and cleaning of hydraulic oil are crucial. As the core component of the baler, the efficiency of the hydraulic system directly affects the performance of the baler. Therefore, regularly checking the quality of the hydraulic oil and maintaining the cleanliness and lubrication of the hydraulic system can effectively improve the operating efficiency and extend the service life of the equipment.

The inspection of the electrical control system and mechanical components should also not be overlooked. During operation, abnormal noise or vibration often indicates loose or worn mechanical parts. In this case, the machine should be stopped immediately for inspection to avoid more serious equipment damage. At the same time, regularly inspect and replace the baler's seals to ensure the equipment's sealing performance and prevent hydraulic oil leakage.

Frequently Asked Questions (FAQ)

1. What are the main functions of a hydraulic scrap metal baler?

The main function of a hydraulic scrap metal baler is to compress and bale scrap metal using a hydraulic system. It compresses scrap metal into blocks or square packages, facilitating storage, transportation, and recycling, greatly improving the efficiency of scrap metal recycling.

2. What types of scrap metal are suitable for hydraulic scrap metal balers?

Hydraulic scrap metal balers are suitable for various types of scrap metal, including iron, aluminum, copper, and alloys. It can adjust the hydraulic pressure according to the hardness and shape of the scrap metal to process different types of metal waste.

3. What are the maintenance methods for hydraulic scrap metal balers?

The maintenance of a hydraulic scrap metal baler mainly includes regularly changing the hydraulic oil, cleaning the hydraulic system, and inspecting the electrical control system and mechanical components. Maintenance of the hydraulic system is particularly crucial; keeping the hydraulic oil clean and properly lubricated can effectively extend the service life of the equipment.

4. How to choose a suitable hydraulic scrap metal baler?

When choosing a hydraulic scrap metal baler, factors such as the type of scrap metal, processing capacity, and compression capability should be considered. At the same time, the equipment's performance, quality, and after-sales service should also be important criteria for selection.