Choosing the right Hydraulic Metal Shear Machine for your industrial needs is crucial for maximizing efficiency and ensuring safety in your operations. This guide will provide a detailed analysis of how to select the best machine for your business, focusing on various aspects such as material types, cutting capabilities, maintenance, safety features, and cost-effectiveness.

Introduction: Why Selecting the Right Hydraulic Metal Shear Machine Matters?

The Hydraulic Metal Shear Machine plays a vital role in industries like metal fabrication, automotive manufacturing, and construction. Choosing the right machine ensures that you can cut materials efficiently, increase productivity, and reduce operational costs. Additionally, the proper shear machine helps enhance the safety of your workplace by providing accurate cuts and preventing accidents during operation.

Understanding the Basics of Hydraulic Metal Shear Machines

How Does a Hydraulic Metal Shear Machine Work?

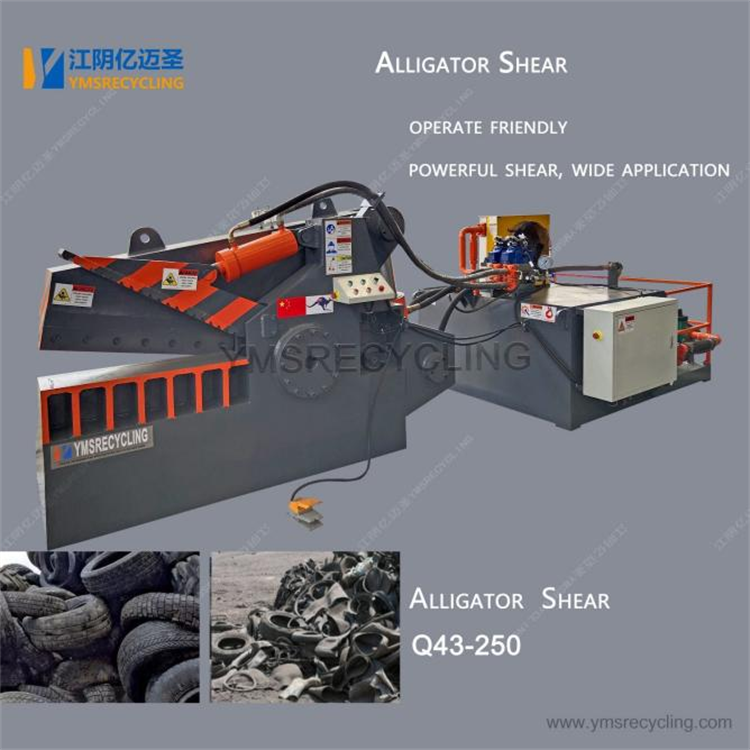

Hydraulic metal shear machines operate by using hydraulic pressure to drive a blade that cuts through metal sheets. The hydraulic system allows for precise control of cutting force, making these machines ideal for cutting thick and tough materials with minimal distortion. These machines are more efficient than manual cutting and provide better precision in high-volume production environments.

Common Applications of Hydraulic Metal Shear Machines

- Metal fabrication: Cutting metal sheets and plates

- Automotive industry: Manufacturing body panels and components

- Construction: Cutting metal for structures and scaffolding

- Recycling: Processing scrap metal for reuse

How to Choose the Right Hydraulic Metal Shear Machine for Your Industrial Needs

1. Consider Your Materials and Cutting Requirements

When selecting a Hydraulic Metal Shear Machine, the first step is to assess the materials you plan to cut and the thickness of the material. Different machines have varying capabilities based on the material type and thickness, so it's essential to choose a machine that aligns with your specific needs.

Cutting Stainless Steel and Other Metals

If you plan to cut stainless steel, it's crucial to select a shear machine designed to handle harder materials. Stainless steel requires a machine that provides higher cutting force to prevent deformation and ensure a clean cut.

Long-tail keyword: Hydraulic metal shear machine for stainless steel cutting

Sheet Metal Cutting

For cutting sheet metal, you should focus on machines that provide smooth cuts for thinner materials. Machines designed for this purpose offer more precise cuts, reducing the amount of post-processing required.

Long-tail keyword: Best hydraulic metal shear machine for sheet metal cutting

2. Consider the Shear Machine's Load Capacity and Cutting Precision

The cutting capacity of the hydraulic shear machine is crucial for ensuring it can handle the thickness and type of material you are cutting. A machine with higher capacity can handle thicker materials but may require more space and higher costs. Additionally, the precision of the cuts affects the quality of the finished product, especially in industries requiring high tolerances.

Compare machines based on their maximum cutting thickness, cutting force, and accuracy to ensure that they meet your operational requirements.

Budget and Cost-Effectiveness

3. Price vs. Performance

When selecting a Hydraulic Metal Shear Machine, it is essential to balance price with performance. While it may be tempting to opt for the cheapest option, it's important to ensure that the machine can handle your needs. Often, a slightly higher investment pays off by improving productivity and reducing maintenance costs.

Long-tail keyword: Affordable hydraulic metal shear machine for small businesses

4. Maintenance Costs and Long-Term Durability

Long-term durability and maintenance costs should also be considered. A lower initial cost might seem attractive, but high maintenance costs over time can outweigh the savings. Be sure to evaluate the total cost of ownership, which includes the frequency and cost of repairs, parts replacement, and service.

Long-tail keyword: How to maintain a hydraulic metal shear machine

Safety Features of Hydraulic Metal Shear Machines

5. Essential Safety Features

Safety is a major consideration when purchasing a hydraulic shear machine. The right machine should include safety features such as emergency stop buttons, protective shields, and automatic shut-off mechanisms to minimize the risk of accidents.

Common Safety Features

- Emergency stop button

- Overload protection

- Automatic blade positioning

- Operator safety shields

Long-tail keyword: Hydraulic metal shear machine safety features

6. Operator Training and Safety Awareness

In addition to machine safety features, it is vital to train operators on safe operation procedures. Proper training reduces the risk of human error and helps prevent accidents on the shop floor.

Choosing the Right Supplier and Brand

7. Evaluating Suppliers and Brands

When purchasing a hydraulic shear machine, it's important to evaluate suppliers based on their reputation, customer service, and after-sales support. Look for companies with experience in the industry and positive customer feedback.

8. Warranty and Support

Check the warranty terms and the availability of technical support before making a purchase. A reliable warranty and responsive customer support can save you time and money in case of future issues with the machine.

Conclusion: Making an Informed Decision

Choosing the right Hydraulic Metal Shear Machine involves evaluating various factors, including material types, machine capacity, budget, safety features, and supplier reputation. By carefully considering your specific requirements and comparing different options, you can select a machine that offers the best value and performance for your industrial needs.

FAQs

- What is the most important factor when choosing a hydraulic metal shear machine? The most important factor is understanding your material types and cutting requirements to select the machine with the appropriate capacity and precision.

- How do I maintain a hydraulic metal shear machine? Regular maintenance includes checking hydraulic fluid levels, inspecting the blades for wear, and ensuring safety features are functional. It's essential to follow the manufacturer's recommended maintenance schedule.

- Can a hydraulic metal shear machine cut stainless steel? Yes, hydraulic shear machines designed for tougher materials can cut stainless steel. Ensure the machine is rated for the material thickness you plan to cut.

- Are hydraulic metal shear machines safe to use? Hydraulic shear machines are safe to use when equipped with proper safety features and when operators are trained in safe operating procedures.

- How can I reduce the long-term costs of owning a hydraulic metal shear machine? Focus on purchasing a durable machine with low maintenance needs, and ensure regular maintenance to prevent costly repairs.