The heavy scrap metal shear machine plays a critical role in metal recycling industries, offering powerful cutting capabilities. However, without regular and proper maintenance, these machines can experience a significant decline in performance and lifespan. In this article, we will explore effective maintenance practices that can ensure your equipment operates efficiently and lasts longer. We will also discuss the importance of correct selection, usage, and upkeep of heavy scrap metal shear machines for sale, the best machines for heavy-duty tasks, and tips for small businesses seeking to extend their machine's life.

Understanding the Basic Operation of a Heavy Scrap Metal Shear Machine

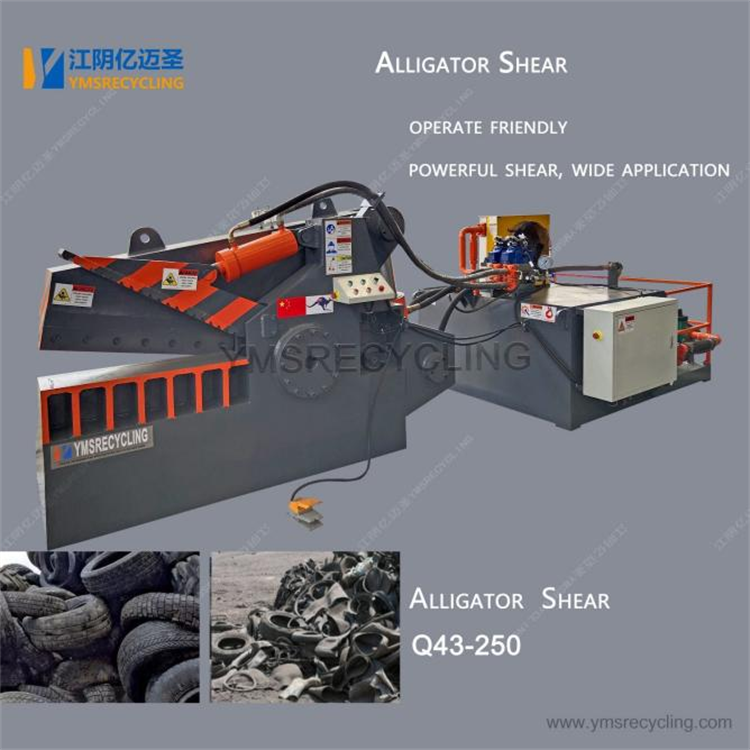

A heavy scrap metal shear machine is designed to cut large pieces of scrap metal into smaller, manageable sizes. This cutting is achieved using hydraulic or mechanical systems that apply immense pressure. However, operating under high loads continuously can lead to wear and tear on crucial components.

Factors affecting the machine's performance include:

- Type of scrap metal being cut.

- Frequency of use and operational load.

- Environmental conditions (e.g., dust, moisture, temperature).

Understanding how the machine works is essential for proper maintenance. Inadequate maintenance can lead to malfunctions, increasing downtime and repair costs. It's vital to consider the best heavy-duty scrap metal shear machine based on your specific business needs, ensuring that it’s capable of handling the required workload without excessive strain on its components.

Common Heavy Scrap Metal Shear Machine Maintenance Mistakes

Many businesses overlook the importance of regular inspections and maintenance. Some of the most common mistakes include:

- Skipping routine checks on the hydraulic system and cutting edges.

- Failing to clean the machine regularly, allowing metal shavings and debris to accumulate.

- Ignoring early signs of wear, leading to costly repairs.

It’s important to ensure that regular maintenance is performed to prevent these mistakes. Comparing maintenance costs and service options can help businesses find the best solution for long-term machine care, avoiding expensive repairs and downtimes.

Key Maintenance Practices to Extend the Lifespan of Your Machine

Proper maintenance ensures that the machine remains operational for years, performing at its peak efficiency. Below are some key practices:

1. Regular Lubrication and Cleaning

Lubrication reduces friction between moving parts and prevents premature wear. Cleaning is just as important to prevent buildup of scrap and debris, which could affect the cutting mechanism.

- Lubricate moving parts, especially cutting edges and hydraulic components, every 100 operational hours.

- Regularly clean the machine to remove scrap metal and dust accumulation that can impede performance.

2. Scheduled Replacement of Worn Parts

Over time, parts such as blades, bearings, and hydraulic seals wear down. Regularly replacing these components is crucial for ensuring optimal functionality.

- Inspect blades and cutting edges every 500 operating hours and replace them as needed.

- Check hydraulic seals and replace any that show signs of wear.

3. Hydraulic System and Electrical System Checks

The hydraulic system is essential for the machine's cutting capabilities. Over time, hydraulic fluid can degrade, causing a drop in performance. The electrical system must also be maintained to prevent short circuits or malfunctions.

- Monitor hydraulic fluid levels and quality, changing it every 1,000 operational hours.

- Inspect the electrical connections to avoid issues with power supply or sensors.

4. Control Cutting Frequency and Load

To avoid unnecessary strain on your heavy scrap metal shear machine for small business operations, it’s essential to control cutting frequency and load. Operating the machine at maximum capacity constantly can accelerate wear and reduce lifespan.

- Limit continuous cutting sessions to avoid overheating the machine.

- Distribute workloads evenly and avoid overloading the shear machine.

How to Choose the Right Heavy Scrap Metal Shear Machine for Your Needs

Choosing the right machine is key to ensuring longevity and efficiency. Here’s what to look for:

- Cutting capacity: Make sure the machine can handle the thickness and type of metal you plan to cut.

- Durability: Look for machines made with durable materials and components designed for heavy-duty tasks.

- Hydraulic and electrical efficiency: Select machines with reliable hydraulic and electrical systems that reduce the likelihood of breakdowns.

Additionally, consider your specific business needs. For example, small businesses might benefit from more affordable options with lower maintenance costs, while larger operations may need machines that can handle larger volumes. Heavy scrap metal shear machine price comparison can help in making informed purchasing decisions.

Common Issues and How to Address Them

Even with proper maintenance, issues may arise over time. Some common problems include:

- Excessive noise: Often caused by worn bearings or insufficient lubrication.

- Hydraulic fluid leakage: Can be fixed by replacing seals and hoses.

- Decreased cutting performance: Typically due to dull blades or misaligned components.

Solution Approach

It’s important to address issues quickly to avoid causing further damage. If problems persist, it’s best to consult a professional technician to ensure the machine remains in optimal condition.

Conclusion

Proper maintenance of your heavy scrap metal shear machine is essential to extend its lifespan and maintain efficiency. Regular cleaning, lubrication, part replacement, and hydraulic checks are all key practices to follow. By adhering to these practices, you can ensure that your machine runs smoothly for years, minimizing downtime and repair costs. Be sure to compare heavy scrap metal shear machine for sale options and choose the best model that fits your operational needs and budget.

FAQs

- What are the signs that my scrap metal shear machine needs maintenance? Regular signs include abnormal noises, reduced cutting efficiency, and visible wear on the parts.

- How often should I lubricate my heavy scrap metal shear machine? Lubricate the machine every 100 operational hours to ensure proper functioning.

- Can small businesses afford high-quality scrap metal shear machines? Yes, there are machines specifically designed for small businesses with lower maintenance and operating costs.

- What are the main causes of hydraulic system failures in shear machines? Contaminated hydraulic fluid, leaks, or worn seals can cause hydraulic system failures.

- How can I determine if my machine is overloaded? If the machine struggles to cut metal or overheats, it is likely overloaded.