Hydraulic metal shear machines, as indispensable equipment in modern metal processing, are widely used in industries such as steel, machinery, and metallurgy. Driven by a hydraulic system, they can achieve precise shearing of various metal materials, meeting the needs of large-scale production and high-precision processing.

Working Principle of Hydraulic Metal Shear Machines

Hydraulic metal shear machines utilize a hydraulic power system to convert the energy of high-pressure liquid into mechanical work force, shearing metal materials through cutting blades. The working principle of the hydraulic system is based on the incompressibility of liquids. When liquid flows in a closed system, it can generate a stable thrust. This force is transmitted to the cutting blades through pressure regulation by the hydraulic pump, thus achieving metal cutting. Compared with traditional mechanical shear machines, the hydraulic system can better control the shearing force, providing a smoother and more precise operation.

Main Technical Characteristics of Hydraulic Metal Shear Machines

The advantages of hydraulic metal shear machines are not only reflected in their powerful shearing capabilities but also in their many unique technical characteristics. First, they have high flexibility and adjustability. The hydraulic system can flexibly adjust the size of the shearing force and the shearing angle according to actual needs, allowing hydraulic shear machines to handle metal materials of different thicknesses and materials. Hydraulic shear machines also have a faster shearing speed, enabling them to complete large-scale metal cutting work in a short time, greatly improving production efficiency.

The hydraulic system also has good stability and reliability. Due to the precise design of the internal hydraulic system of the hydraulic metal shear machine, it can maintain continuous high-efficiency performance during operation without affecting the shearing quality due to excessive wear or system pressure fluctuations. At the same time, hydraulic shear machines are equipped with high-strength blades and wear-resistant materials, ensuring long-term use without performance degradation due to wear.

Application Fields of Hydraulic Metal Shear Machines

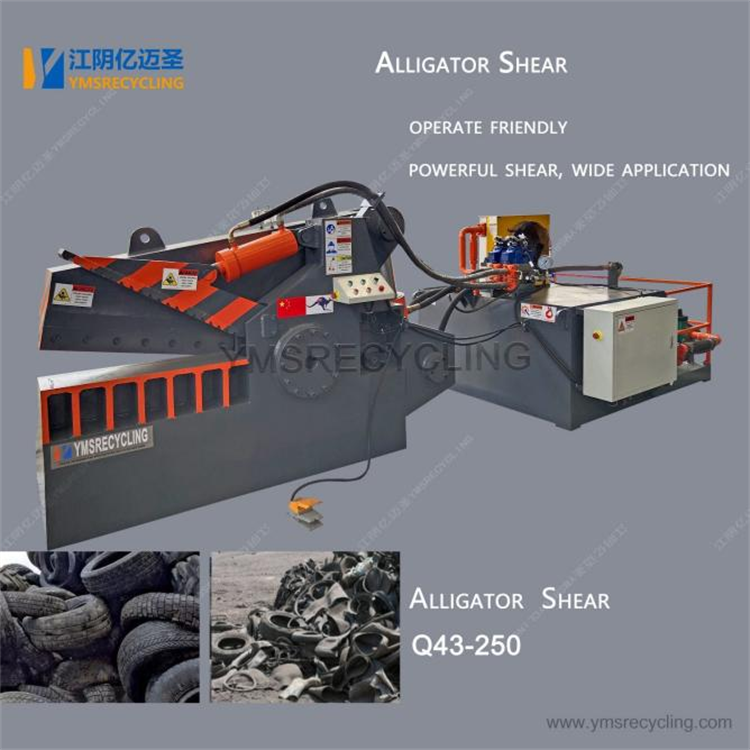

The widespread application of hydraulic metal shear machines stems from their powerful shearing capabilities and excellent processing accuracy. They play a crucial role in metal processing, especially in large-scale production. Whether in steel smelting, metal recycling, automobile manufacturing, or in the construction and shipbuilding industries, hydraulic metal shear machines can accurately complete the shearing tasks of various metal materials. In the steel industry, hydraulic metal shears are commonly used to cut steel plates, reinforcing bars, and other materials. Their efficient cutting capabilities allow steel mills to process raw materials faster, thus improving production efficiency. In the metal recycling industry, hydraulic metal shears are widely used for the dismantling and recycling of scrap metal, playing a particularly important role in dismantling cars and electronic equipment. The recycled scrap metal can be reintroduced into production, contributing to environmental protection and resource recycling.

Advantages of Hydraulic Metal Shears

As an advanced metal processing equipment, hydraulic metal shears have many significant advantages. Their precise cutting performance and high production efficiency make them indispensable equipment in many industries. The compact design of hydraulic metal shears requires less space, is easy to operate, and facilitates automated production. The efficient energy conversion of the hydraulic system makes hydraulic shears outstanding in energy saving, meeting the modern industrial demand for energy conservation and environmental protection.

Frequently Asked Questions (FAQ)

1. What metal materials are suitable for cutting with hydraulic metal shears?

Hydraulic metal shears are suitable for various metal materials, including steel plates, aluminum plates, copper plates, iron plates, etc., and are especially suitable for processing thicker metal materials.

2. Is the maintenance of hydraulic metal shears difficult?

Maintenance of hydraulic metal shears requires regular inspection of the hydraulic system, cleaning of the blades, and lubrication of the equipment. Although the maintenance work is somewhat complex, regular maintenance can effectively extend the equipment's service life and ensure its efficient operation.

3. What is the cutting accuracy of hydraulic metal shears?

Hydraulic metal shears have high cutting accuracy, capable of precisely controlling the cutting thickness and angle, and are therefore widely used in processing applications requiring high precision.

4. What are the advantages of hydraulic metal shears compared to traditional mechanical shears?

The main advantages of hydraulic metal shears are their adjustable cutting force, higher stability, and greater adaptability. Compared to traditional mechanical shears, hydraulic shears can handle thicker and harder metal materials, and the cutting effect is smoother.