In modern industrial production and waste recycling, custom metal baler machines are increasingly becoming essential equipment for companies to improve efficiency and reduce costs. With increasingly stringent environmental policies and the development of the metal recycling industry, companies have higher requirements for the compression, baling, and transportation of metal waste. Traditional equipment can no longer meet the customized and diversified production needs. Customized metal baler machines are not only more flexible in function but also achieve breakthrough performance improvements, becoming an indispensable core piece of equipment in the metal recycling and waste treatment field.

Design Advantages of Customized Metal Baler Machines

Compared to standardized equipment, custom metal baler machines fully consider the customer's production environment and processing needs during the design phase. Designers, through in-depth analysis of different types of metals, different waste volumes, and operating environments, tailor solutions to meet the actual needs of enterprises. This customized design not only ensures the stability of the equipment during long-term operation but also greatly improves production efficiency and safety performance.

Another significant advantage of customized metal baler machines lies in the intelligent operating system. Modern customized metal balers are generally equipped with automatic control systems, achieving fully automated operation through functions such as pressure monitoring, baling strength adjustment, and fault warning. This intelligent control not only reduces the risk of manual intervention but also adjusts baling parameters according to different metal materials, ensuring the compactness of the balers and the safety of transportation.

High-Performance Hydraulic Systems and Power Optimization

The hydraulic system is the core power source of the metal baler. A high-performance hydraulic system provides stable and powerful pressure output, enabling the equipment to operate efficiently when dealing with metal scrap of varying densities, thicknesses, and shapes. Through precise pressure control and hydraulic circuit optimization, customized metal balers can achieve continuous operation without overheating or excessive power loss, thereby extending equipment life and reducing maintenance costs.

Meanwhile, the optimization of the power system is not only reflected in pressure control but also in energy management and noise control. Modern customized equipment emphasizes energy conservation and environmental protection, achieving a low-energy, high-efficiency operating mode through the coordinated design of the power and hydraulic systems. This not only meets the national energy conservation and emission reduction policy requirements but also significantly reduces the production costs of enterprises, making the investment return cycle more controllable.

Diverse Baling Methods and Enhanced Adaptability

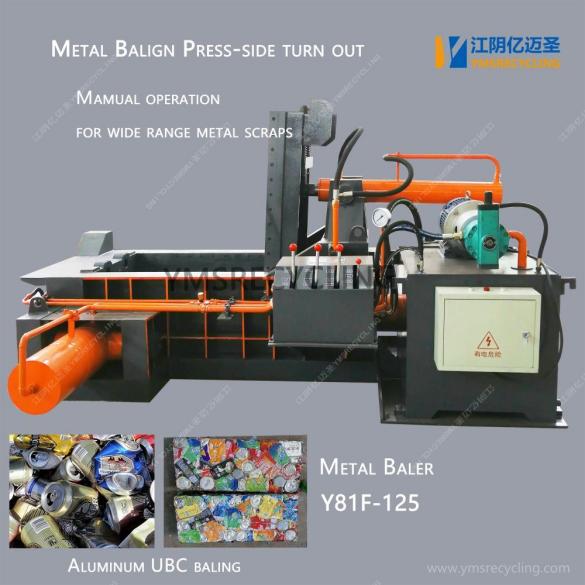

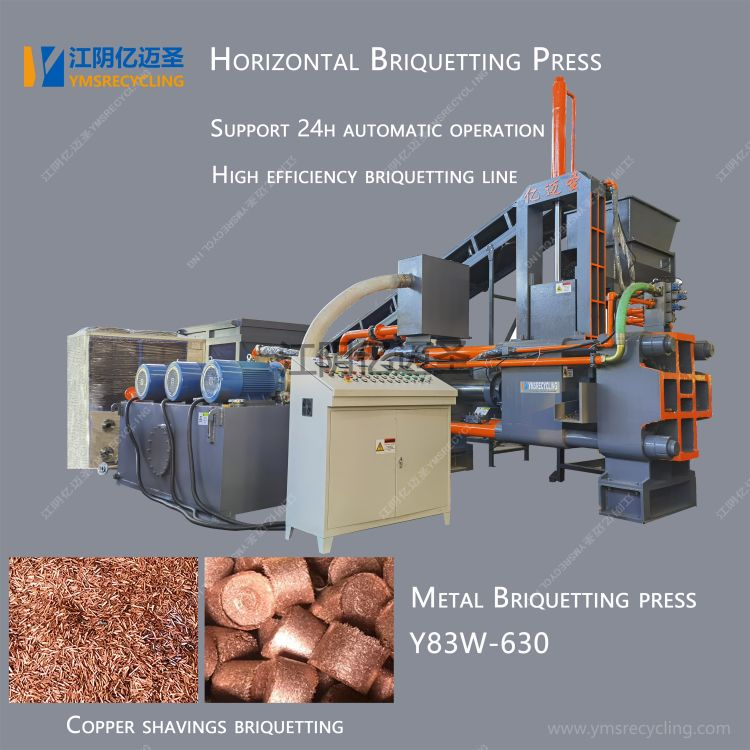

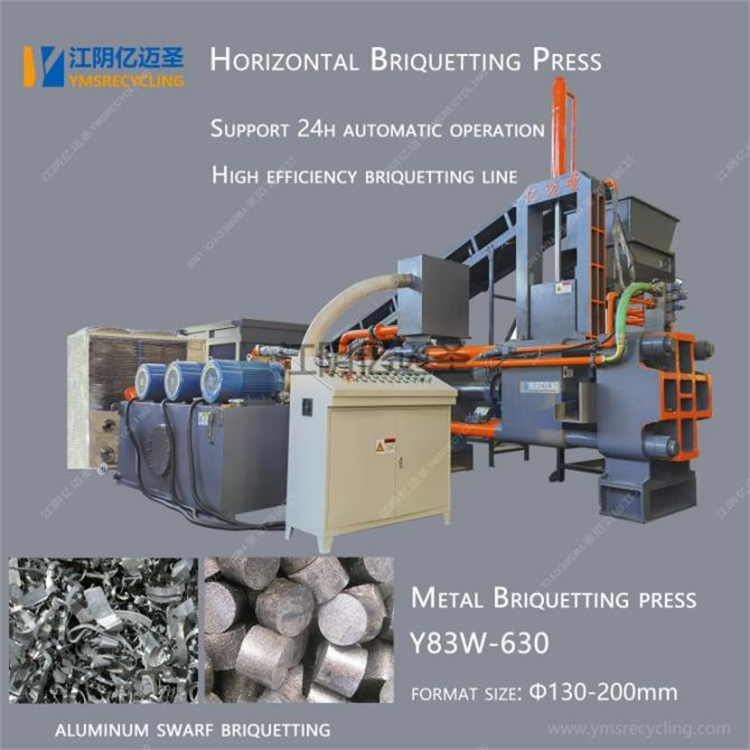

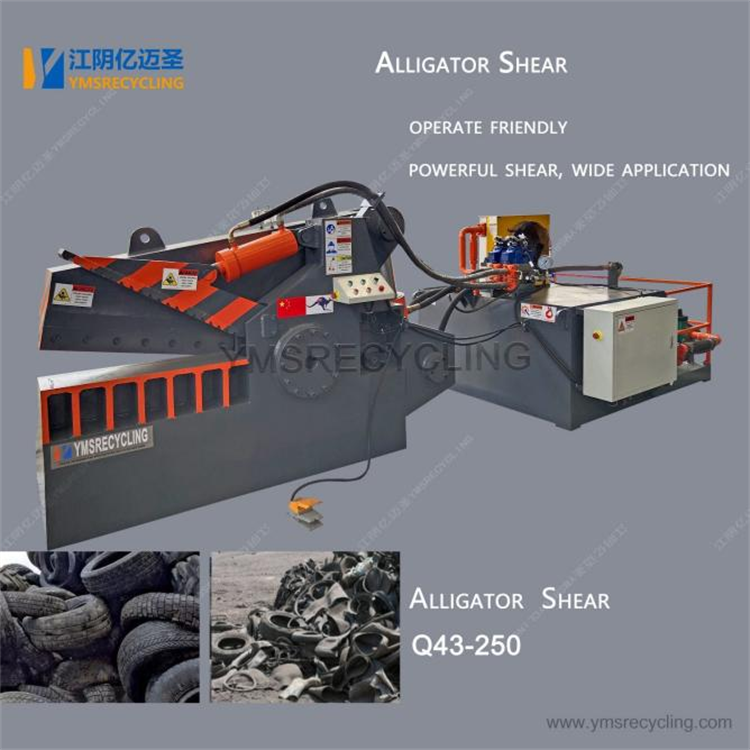

Different types of metal scrap require different baling methods during recycling. Customized metal balers can flexibly select longitudinal compression, transverse compression, or mixed compression modes based on the metal material, thickness, and shape. Through diversified baling designs, the equipment not only increases briquette density but also maximizes space savings during transportation and storage.

Customized metal balers excel in adaptability. Whether it's cold-rolled steel sheets, scrap iron and copper, industrial aluminum, or lightweight metal fragments, the equipment can achieve optimal compression results by adjusting operating parameters. This high adaptability reduces the frequency of equipment replacement and adjustment, decreases operator training costs, and improves overall production efficiency.

Automated Control and Intelligent Monitoring

Custom metal balers demonstrate remarkable intelligence. Modern equipment is generally equipped with intelligent control systems that monitor equipment operating status in real time via sensors, including key data such as hydraulic pressure, temperature, equipment load, and baling frequency. This data not only provides real-time reference for operators but also enables fault warnings and maintenance guidance through remote monitoring systems.

Intelligent control is also reflected in the automatic optimization of the baling process. Through built-in algorithms, the equipment can automatically adjust the baling force and number of cycles based on the type of metal and the volume of waste, achieving efficient and precise baling. This automation greatly reduces the complexity of manual operation and minimizes the impact of human error on production efficiency and safety.

Environmental Protection and Sustainable Development

In the metal recycling industry, environmental protection and sustainable development have become core drivers of enterprise development. Custom metal baler machines significantly reduce the volume of metal waste through high-density compression and precise baling, thereby reducing transportation energy consumption and storage space. Simultaneously, the intelligent control system enables energy-saving operation, reducing energy waste and aligning with green production principles.

Customized equipment also emphasizes environmental protection in the selection of production materials. For example, the use of high-strength alloy steel structures not only improves equipment durability but also reduces material consumption and maintenance frequency, extending the equipment's lifespan. This green design concept not only aligns with policy guidance but also enhances the company's brand image within the industry.

Customized Services and Industry Application Prospects

Companies choosing a Custom metal baler machine are not merely purchasing equipment but also obtaining a complete customized solution. From initial needs assessment and solution design to equipment manufacturing and after-sales service, every step is customer-centric, ensuring the equipment truly meets the company's production needs. The core value of customized services lies in their flexibility and scalability; regardless of changes in production scale, the equipment can be adjusted and upgraded accordingly.

In industry applications, customized metal balers are widely used in metal recycling plants, steel companies, automobile dismantling plants, and large industrial waste treatment centers. With the continuous development of industrial waste recycling technology and the gradual improvement of environmental policies, the market demand for customized metal balers will continue to grow, and their value in resource recycling and green production will become increasingly prominent.

Conclusion

Custom metal balers, with their high-performance hydraulic systems, intelligent control, diverse baling methods, and environmentally friendly and energy-saving designs, are becoming important equipment in the metal recycling and waste treatment fields. By introducing customized metal balers, companies can not only improve production efficiency and reduce operating costs but also gain significant advantages in environmental protection and sustainable development. In future industrial development, the application prospects of this type of equipment are broad, playing a vital role in promoting resource recycling, enhancing corporate competitiveness, and achieving green production goals.