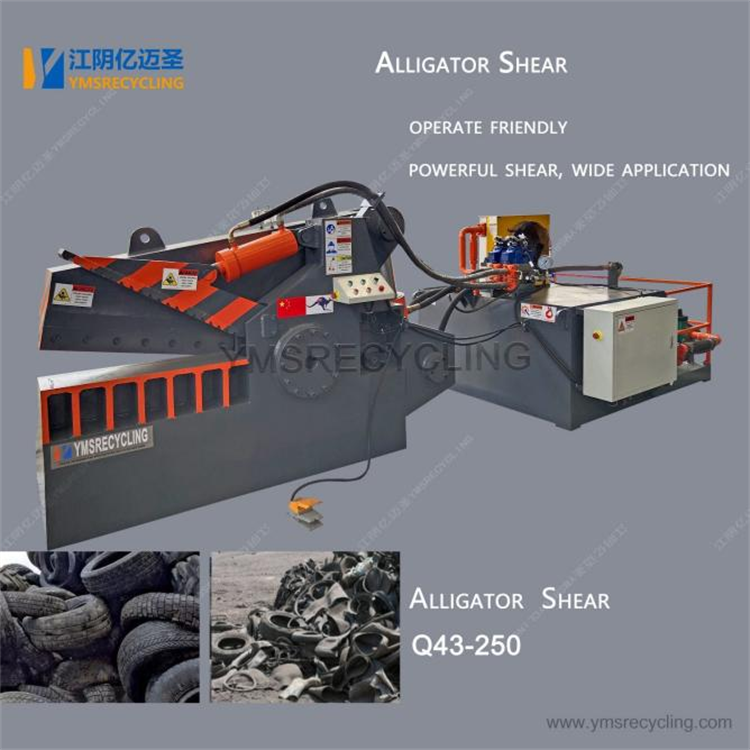

In the modern metal recycling and scrap processing industry, heavy scrap metal shear machines have become an indispensable core equipment. With the continuous development of industrial production and the recycling of scrap metal, the demand for efficient, stable, and safe shearing equipment is becoming increasingly strong. Heavy-duty scrap metal shear machines, with their superior performance and durability, are gradually changing traditional scrap processing methods and becoming an important guarantee for improving enterprise efficiency and profitability.

High-Efficiency Shearing: The Core Advantage of Heavy Scrap Metal Shear Machines

Heavy-duty scrap metal shear machines are renowned for their powerful shearing capabilities, easily handling the cutting needs of various types of steel, iron, and large metal scrap. Their structural design fully considers the hardness and thickness of metal materials, maximizing shearing force output through an optimized hydraulic system and high-strength blades. This not only ensures processing efficiency but also reduces equipment wear, thus extending its service life.

Another manifestation of high-efficiency shearing is production continuity. Traditional metal cutting equipment often experiences blockages and downtime when processing heavy scrap, while heavy-duty scrap metal shear machines, with their stable hydraulic control system, can achieve long-term, high-load operation, maintaining the smooth flow of the production line. Whether it's steel plates, iron pipes, or large structural scrap, the equipment can quickly process them through precise shearing, greatly improving material recycling and reuse efficiency.

Optimized Structure: Robust and Durable Mechanical Design

The mechanical structure of the heavy-duty scrap metal shear machine is meticulously designed, balancing robustness and ease of operation. The overall frame is welded from high-strength steel, possessing excellent compressive and torsional resistance, and can withstand continuous heavy-duty operation without deformation. At the same time, the blades undergo special heat treatment and surface hardening, maintaining their sharpness during the shearing process, reducing maintenance frequency and replacement costs.

The internal hydraulic system is rationally designed, achieving precise control through multi-way valves and pressure regulating devices, resulting in smooth and stable shearing action. The operating interface is simple and intuitive, requiring no complex training, greatly reducing operating difficulty and safety risks. This design, which balances performance and operability, makes heavy-duty scrap metal shear machines perform exceptionally well in industrial scrap processing.

Energy Saving and Environmental Protection: Enhancing Enterprises' Sustainable Development Capabilities

In modern industrial production, energy saving and environmental protection have become key concerns for businesses. Heavy-duty scrap metal shears are designed with energy consumption and environmental factors in mind. The hydraulic system is optimized to minimize energy loss during the shearing process, while also reducing noise and vibration, meeting green production standards.

At the same time, heavy-duty scrap metal shears can quickly cut large pieces of scrap into smaller pieces for reprocessing, facilitating subsequent remelting or recycling. This efficient material decomposition capability not only increases the scrap recycling rate but also reduces transportation and storage costs, further enhancing the economic benefits and environmental image of the enterprise.

Safety Performance: Providing Comprehensive Protection for Operations

Safety is the primary consideration in metal shearing. Heavy-duty scrap metal shears have multiple safety features. The equipment is equipped with protective covers and emergency stop devices to effectively prevent accidents during the shearing process. The hydraulic system's overload protection mechanism prevents equipment damage under abnormal loads, ensuring production safety.

The equipment's structure is optimized with ergonomic design, providing ample operating space and convenient maintenance. The ease of regular maintenance and servicing also reduces safety hazards caused by equipment malfunctions, making the entire scrap processing process more reliable and efficient.

High Adaptability: Potential for Multi-Field Applications

Heavy-duty scrap metal shears are not only suitable for steel mills and scrap metal recycling companies but can also be used in various industrial fields such as shipbuilding, automobile dismantling, and mechanical processing. Its powerful shearing capacity and stable performance allow it to handle metal scrap of various sizes, shapes, and materials. Whether it's large steel structures or heavy metal pipes, the equipment can quickly and accurately complete the shearing, meeting the diverse needs of different industries for scrap processing.

At the same time, the adjustable shearing thickness and amplitude provide enterprises with greater flexibility. Operators can flexibly adjust equipment parameters according to the specific scrap type and processing requirements, achieving precise shearing and improving scrap processing efficiency.

Maintenance and Service: Extending Equipment Lifespan

Heavy-duty scrap metal shears are designed with maintenance convenience in mind. Key components such as the hydraulic system, blades, and motor can be easily disassembled and replaced, significantly reducing downtime. Manufacturers typically provide comprehensive technical support and after-sales service to ensure the equipment maintains efficient operation during long-term use.

The equipment has a long service life and strong wear resistance, reducing long-term operating costs. Through regular maintenance and proper operation, the heavy-duty scrap metal shear can operate stably for many years under high-load working conditions, becoming an important guarantee for stable production in enterprises.

FAQ

Q1: What types of metal scrap are suitable for the heavy-duty scrap metal shear?

The heavy-duty scrap metal shear can process various metal scraps, including steel plates, iron pipes, aluminum materials, and other large metal structural components, meeting the diverse needs of industrial waste recycling.

Q2: Is the equipment difficult to operate?

The equipment features a simple and intuitive operating interface, equipped with a hydraulic control system and safety protection devices. It is easy to operate and requires minimal professional training for safe use.

Q3: How can I extend the equipment's service life?

By regularly checking the hydraulic system, blade wear, and mechanical lubrication, and performing maintenance according to the manufacturer's recommendations, you can significantly extend the equipment's service life and maintain efficient and stable operation.

Q4: Is the equipment energy-efficient?

The heavy-duty scrap metal shear is designed with energy-saving optimization. The hydraulic system has high energy utilization efficiency, and the shearing process is smooth and efficient. The overall energy consumption is low, meeting modern industrial energy-saving and environmental protection requirements.