With the increasing global demand for scrap metal recycling, the hydraulic scrap metal baler machine, as a key piece of equipment, has become indispensable in various metal recycling and processing industries. This equipment not only significantly improves metal recycling efficiency but also effectively reduces the volume of scrap metal, facilitating subsequent transportation and reprocessing.

I. Working Principle of Hydraulic Scrap Metal Baler Machine

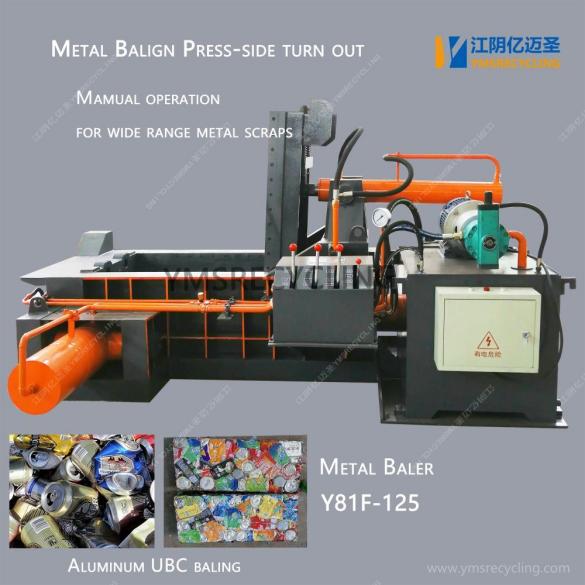

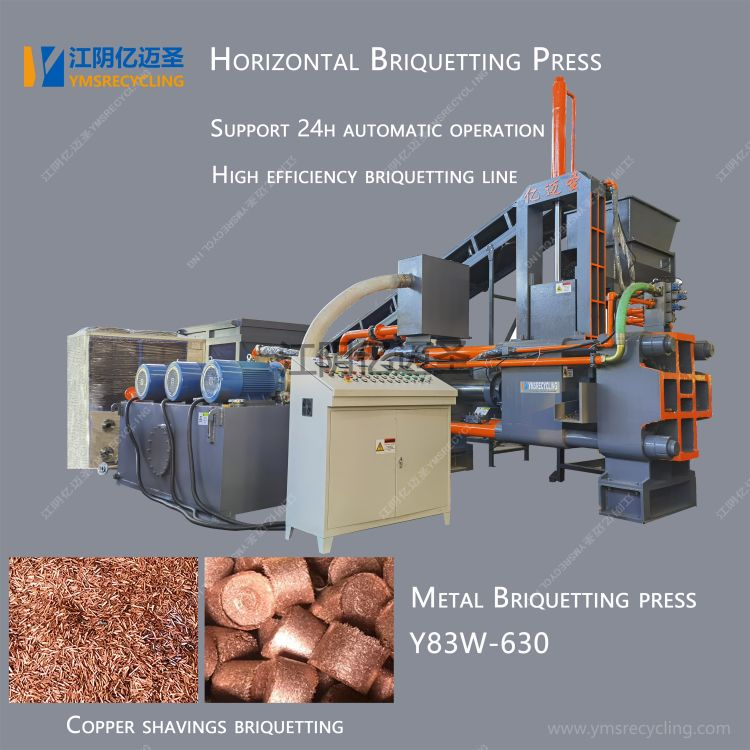

The hydraulic scrap metal baler machine is primarily operated through a hydraulic system. Its working principle is to use a hydraulic cylinder to push the metal material into the compression chamber, where it is compressed multiple times to form a dense metal bale. The high pressure of the hydraulic system allows the scrap metal to be tightly baled in a short time, reducing its volume and facilitating further processing or transportation.

The hydraulic system typically includes components such as hydraulic cylinders, oil pumps, and control valves. By adjusting the flow and pressure of the hydraulic oil, the baling process can be flexibly adjusted according to the type and characteristics of different scrap metals, making the baling process more efficient and stable. Compared to traditional manual baling methods, the hydraulic scrap metal baler machine can significantly improve work efficiency and reduce labor costs and operational risks.

II. Application Characteristics of Hydraulic Scrap Metal Baler Machine

The hydraulic scrap metal baler machine is widely used in the metal recycling industry, mainly in the following aspects:

High Efficiency

One of the biggest advantages of the hydraulic scrap metal baler machine is its high working efficiency. Compared to traditional manual operations or other types of baling equipment, the hydraulic baler has a faster baling speed and can complete the compression and processing of a large amount of scrap metal in a shorter time. This is especially important for companies that need to recycle and process large quantities of scrap metal.

Strong Compression Capacity

The hydraulic scrap metal baler machine utilizes the powerful pressure of the hydraulic system to compress scrap metal into dense bales. These bales not only reduce volume but also increase storage density, lowering storage and transportation costs. The baled metal blocks are uniform in shape and size, making them ideal for subsequent processing, such as smelting.

Simple Operation

Although the internal structure of the hydraulic scrap metal baler machine is relatively complex, its operation is very simple. Modern hydraulic balers are usually equipped with intelligent control systems, allowing operators to simply set the parameters, and the equipment will automatically complete the baling operation. This design greatly improves production efficiency and reduces human error.

Strong Adaptability

The hydraulic scrap metal baler can handle various types of scrap metal, including iron, aluminum, copper, and stainless steel. Whether it's light or heavy metal, it can provide a suitable baling solution. This gives the hydraulic scrap metal baler broad application prospects in various metal recycling companies.

Energy Saving and Environmentally Friendly

In today's world, where environmental protection is increasingly valued, the hydraulic scrap metal baler reduces resource waste through its efficient operation, meeting the requirements of green manufacturing. It not only reduces the volume of scrap metal but also effectively saves transportation costs, thus saving companies a significant amount of money. At the same time, the hydraulic system design is relatively energy-efficient and does not consume excessive energy during use.

III. Market Prospects of Hydraulic Scrap Metal Balers

With the gradual strengthening of global environmental protection policies and the continuous development of the metal recycling industry, the market demand for hydraulic scrap metal balers continues to grow. Many countries and regions are increasing their efforts in recycling scrap metal, and the introduction of relevant policies has promoted the rapid development of the scrap metal recycling industry.

In this context, the demand for hydraulic scrap metal balers is also constantly rising. Especially in countries and regions with rapid industrialization, the recycling and processing of metal waste has become an important part of social development. The hydraulic scrap metal baler, as an efficient and environmentally friendly equipment, perfectly meets this demand. In the future, with continuous technological innovation, the functions of hydraulic scrap metal balers will become more complete, and the market potential is enormous.

IV. Purchasing Guide for Hydraulic Scrap Metal Balers

When choosing a hydraulic scrap metal baler, companies should select based on their actual needs. Consider the type and quantity of scrap metal to be processed. For companies that need to process a large amount of scrap metal, a device with a higher processing capacity should be chosen, while companies processing less scrap metal can choose equipment suitable for small-scale operations.

The working efficiency of the equipment should also be considered. Different brands and models of hydraulic scrap metal balers have significant differences in working efficiency. When choosing, companies should pay attention to the baling speed, compression force, and stability of the equipment.

Finally, after-sales service is also crucial. As a high-precision device, the daily maintenance of the hydraulic scrap metal baler is particularly important. Choosing a supplier with good after-sales service guarantees can effectively avoid the impact of equipment failures and ensure smooth production.

V. FAQ

1. What is the working principle of a hydraulic scrap metal baler?

A hydraulic scrap metal baler uses a hydraulic system to push metal materials into a compression chamber, and then compresses the scrap metal into compact bales using the pressure of a hydraulic cylinder.

2. What types of scrap metal can a hydraulic scrap metal baler process?

A hydraulic scrap metal baler is suitable for processing various types of scrap metal, including iron, aluminum, copper, and stainless steel.

3. What is the service life of a hydraulic scrap metal baler?

The service life of a hydraulic scrap metal baler is closely related to the brand, quality, and daily maintenance of the equipment. Generally, with proper maintenance, a hydraulic scrap metal baler can last for more than 10 years.

4. How to choose a suitable hydraulic scrap metal baler?

When choosing a hydraulic scrap metal baler, companies should consider factors such as the type of scrap metal, processing volume, equipment efficiency, and after-sales service.

5. What aspects should be paid attention to in the maintenance of a hydraulic scrap metal baler?

During daily maintenance, it is necessary to regularly check the oil level and oil quality of the hydraulic system, clean the inside of the equipment, and ensure the normal operation of all components. At the same time, the sealing performance of the equipment should be checked regularly to prevent oil leakage.

Summary

As a modern metal recycling and processing equipment, the hydraulic scrap metal baler has become an important tool in the scrap metal recycling industry due to its high efficiency, energy saving, and environmental protection characteristics. With the continuous development of technology, the performance of hydraulic scrap metal balers will be further improved, and market demand will continue to grow. When choosing a suitable hydraulic scrap metal baler, companies need to comprehensively consider the equipment performance, after-sales service, and maintenance aspects to ensure the long-term stable operation of the equipment.