At a time when the concept of environmental protection is becoming more and more popular, scrap metal recycling is becoming the core link in achieving green manufacturing and circular economy. The key to supporting the efficient operation of this industry is Scrap Metal Recycling Equipment. With the development of intelligent and automated technologies, modern scrap metal recycling equipment has not only improved processing efficiency, but also promoted technological innovation in the entire industry.

Why must scrap metal be recycled? The great value of resource recycling

The mining and smelting of metal resources not only consumes a lot of energy, but also causes irreversible damage to the environment. In contrast, the energy consumption and pollution of recycling scrap metal are greatly reduced. For example, recycled aluminum only requires 5% of the energy consumption of original aluminum smelting; steel recycling can reduce carbon emissions by more than 70%. This makes scrap metal recycling equipment a key tool for promoting energy conservation and emission reduction and sustainable resource utilization.

List of mainstream scrap metal recycling equipment types

There are many types of scrap metals, from steel, aluminum, copper to stainless steel and alloy materials, and their recycling and processing methods vary from material to material.

1. Metal Shear Machine

It is suitable for rough processing and cutting of large-sized metal materials such as scrap steel bars, steel sections, and car shells. Common ones include crocodile shears, gantry shears, and hydraulic shears. The equipment has the characteristics of large shearing force, stable structure, and convenient operation.

2. Metal Shredder

It is used to break metal products into small pieces or particles for subsequent smelting or packaging and transportation. It is especially suitable for processing mixed metals such as scrap home appliances, car shells, and aluminum alloy doors and windows. Modern crushers are mostly equipped with intelligent recognition systems and dust removal and noise reduction devices.

3. Magnetic & Eddy Current Separator

It is used to recover non-ferrous metals and non-metallic parts in the mixture, automatically separate ferromagnetic materials, aluminum and copper and other metals, and improve the recovery purity and efficiency. This equipment is particularly critical for the treatment of waste electronic products, waste circuit boards, etc.

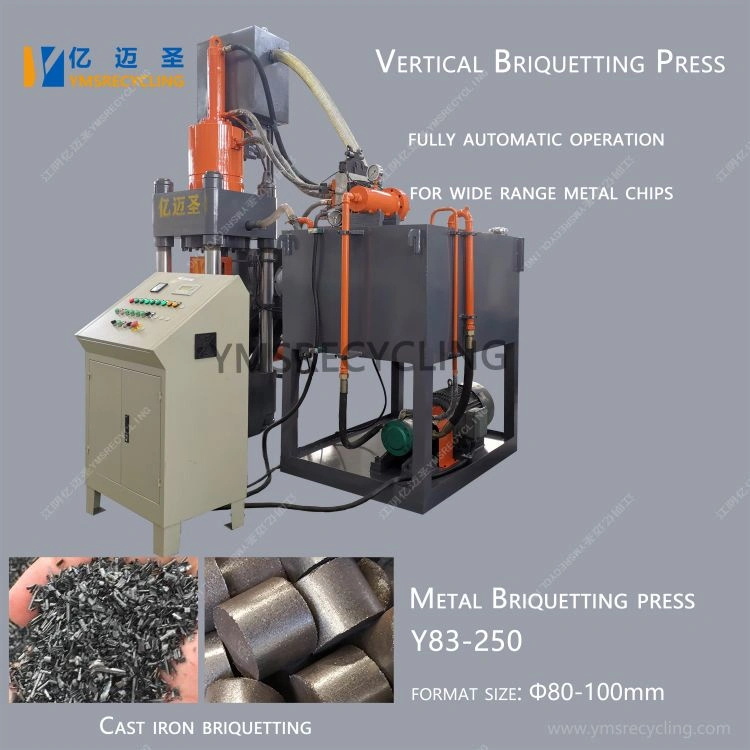

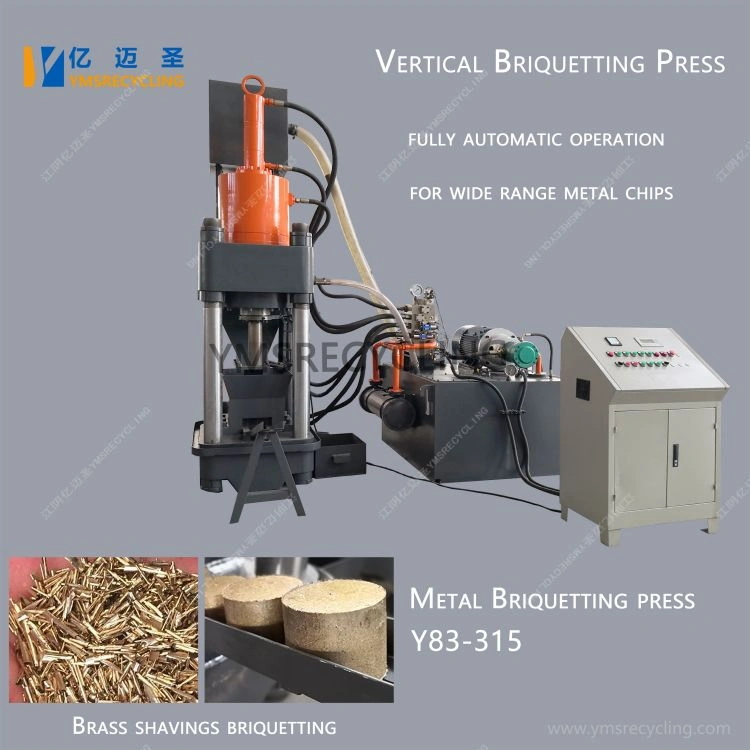

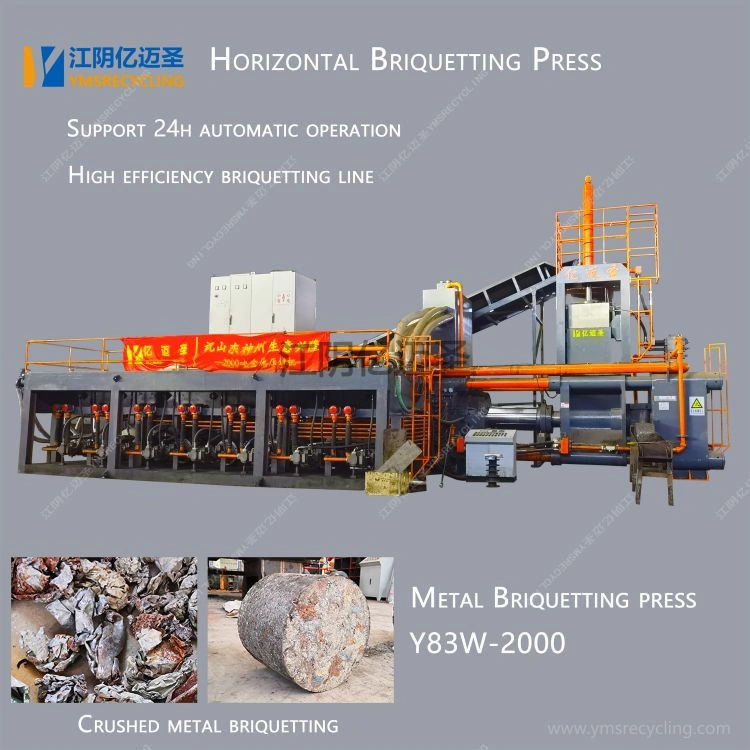

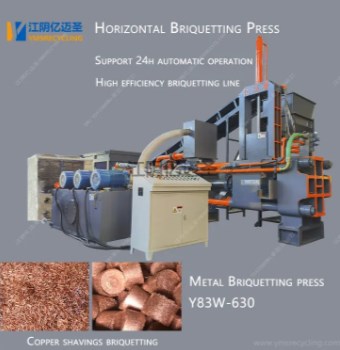

4. Metal Baler Machine

Compress and pack the processed metal into a regular shape for easy storage, transportation and smelting. According to the compression method, it is divided into vertical, horizontal and fully automatic types, and is widely used in scrap recycling stations and large smelters.

Technology upgrade: Intelligence drives the equipment to "fine" development

With the rapid development of industrial automation, scrap metal recycling equipment is also evolving towards intelligence and efficiency:

Automation control system: PLC programming combined with touch screen operation to achieve process control, alarm protection and remote monitoring.

Intelligent identification and sorting: Equipped with AI visual recognition system, it automatically identifies different metal materials and greatly improves sorting accuracy.

Modular design: Users can choose module combinations according to the type of raw materials to improve the adaptability and scalability of the equipment.

Environmental protection supporting systems: such as spray dust removal, noise shielding and other systems, which meet the requirements of national environmental protection regulations.

How to choose the right scrap metal recycling equipment?

Choosing the right scrap metal recycling equipment is not only related to the recycling efficiency, but also directly affects the economic benefits of the enterprise.

Raw material type and specification: Different metal materials and sizes determine the model and configuration of the equipment.

Processing capacity requirements: Select the capacity range of the equipment according to the daily output to avoid overload or waste of resources.

Automation and intelligence level: Give priority to equipment equipped with intelligent control systems to reduce labor costs.

Environmental performance: It should meet local environmental regulations and have dust removal, noise reduction, and exhaust gas treatment functions.

After-sales and maintenance: Choose a brand manufacturer with a professional service team and spare parts guarantee to ensure stable operation in the later stage.

Wide application in the industry: From small recycling stations to large metallurgical enterprises

The scope of application of scrap metal recycling equipment is very wide.

Urban renewable resource recycling station: Use small and medium-sized crushing and baling integrated machines, which are suitable for mobile operations.

Industrial enterprise metal scrap recycling: Automated shearing and baling system to improve the recycling rate of metal resources in the factory.

Automobile dismantling plant: High-power metal crushing and magnetic separation line, which can process the entire vehicle body and components.

Smelter: Heavy gantry shears and baling equipment, used for raw material pretreatment, to improve the efficiency of furnace smelting.

Scrap metal is no longer the "tail" of industry, but the "starting point" of new resources. Scrap metal recycling equipment is the technical fulcrum for achieving this transformation. Only by choosing suitable, advanced and intelligent equipment can enterprises stand out in the resource recycling race. With the dual support of policy support and technological progress, the scrap metal recycling industry will usher in a new round of high-quality development in the future.