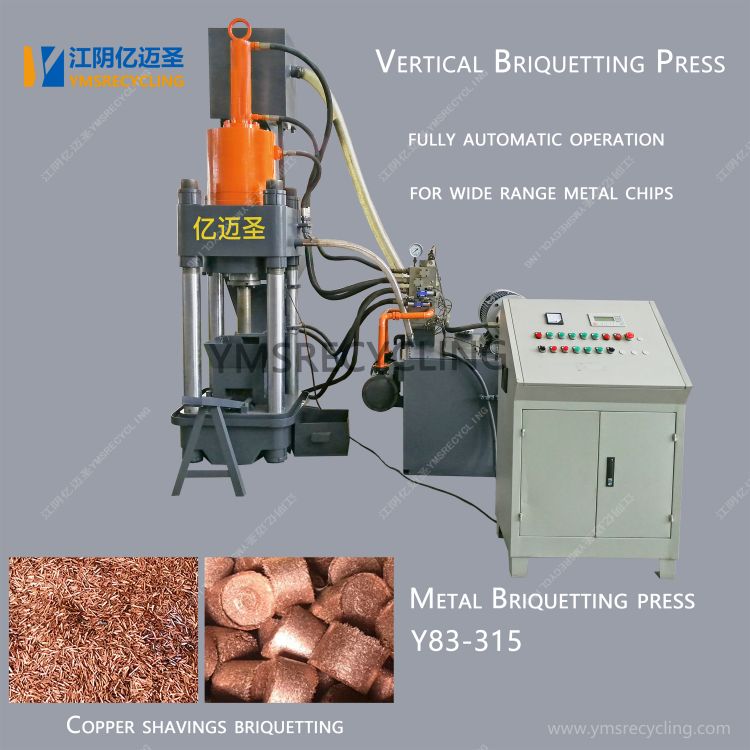

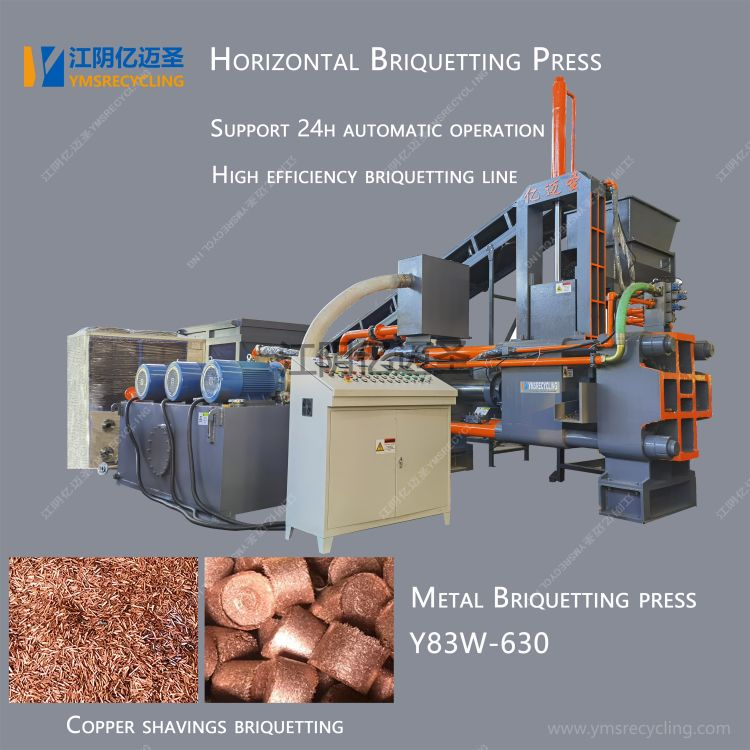

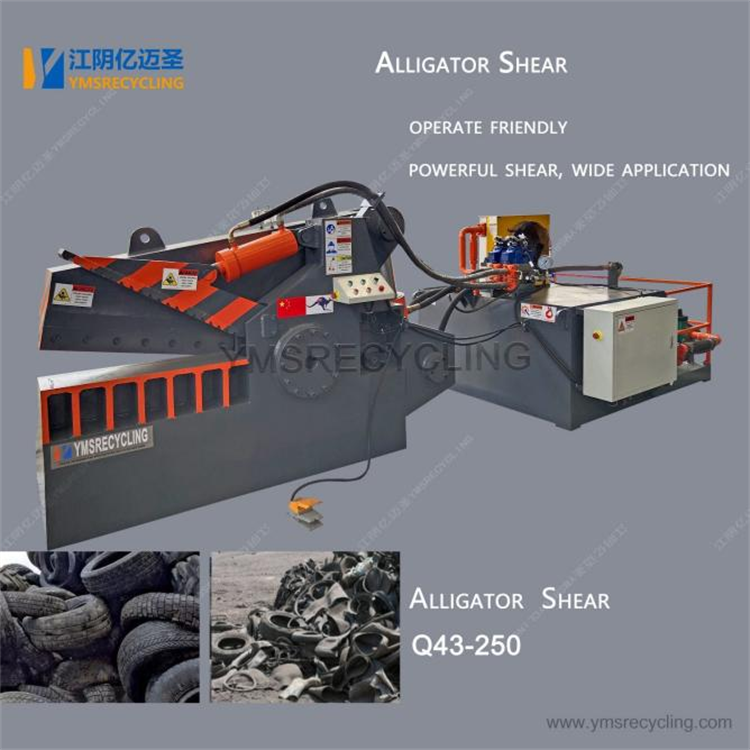

Under the general trend of resource recycling, scrap metal baler machine, as a key equipment in the metal recycling industry, is playing an increasingly important role. It can squeeze various scrap metal scraps, steel shavings, scrap steel, scrap iron, scrap copper, scrap aluminum, etc. into qualified furnace materials of regular shapes, greatly improving the efficiency and benefits of metal recycling.

1. Working principle: strong pressure creates efficient compression

Scrap metal baler machine usually adopts a hydraulic drive system. When it is working, the motor drives the oil pump to operate, extracts hydraulic oil from the oil tank, and transports the high-pressure oil to each hydraulic cylinder through the hydraulic oil pipe. The piston in the cylinder reciprocates under the push of the high-pressure oil, and then drives the compression plate to compress the scrap metal placed inside the machine. For example, in a common horizontal baler, the push block cylinder first pushes the scrap metal to the designated position, the feeding cylinder performs feeding operation, and then the main cylinder applies strong pressure to compress the scrap metal tightly into blocks, and finally the compressed metal blocks are pushed out by the push block cylinder. The whole process utilizes the property of metal materials that can produce plastic deformation under the action of external force. By applying sufficient external force, the scrap metal is formed into a tight bundle.

II. Significant features: Multiple advantages help recycling work

(I) Powerful power, stable and reliable

All adopt hydraulic drive, and the hydraulic system can provide strong and stable pressure to ensure that the baler runs smoothly, safely and reliably during operation. Compared with other drive modes, the failure rate of hydraulically driven equipment can be reduced by about 30% under the same working intensity, greatly reducing the equipment maintenance cost and downtime.

(II) Flexible operation mode

It has manual or PLC automatic control operation mode. The manual operation mode is suitable for small-scale operations or situations with high requirements for operation accuracy. The operator can flexibly adjust the operation steps according to the actual situation. The PLC automatic control mode greatly improves the efficiency of large-scale production, can realize automated production processes, and reduce the tediousness and errors of manual operations.

(III) Diverse discharging forms

The discharging forms are rich, including side-flipping bags, side-push bags, front-push bags or no discharging. Different discharging methods are suitable for different application scenarios and subsequent processing needs. For example, the side-flipping bag is simple to operate and convenient to discharge, and is often used in places such as scrap metal recycling plants; the side-push bag series can achieve continuous work flow and is deeply loved by companies such as copper wire packaging and scrap aluminum packaging; the front-discharging bag series has excellent performance in light and thin material packaging and compression with its high-configuration hydraulic system and large-flow hydraulic oil circuit.

(IV) Convenient installation and power selection

No foot screws are required for installation, which simplifies the installation process and saves installation time and cost. In places without power supply, diesel engines can also be used as power, which can adapt to various complex working environments and provide great convenience for users.

III. Wide application: multiple industries play a key role

Scrap metal balers are widely used in multiple industries. In the steel industry, scrap steel and other scraps can be compressed into blocks for remelting and improving production efficiency; in the automobile manufacturing and dismantling industry, the dismantled automobile shells, parts and other metal scraps can be packaged for easy storage and transportation; in the machinery manufacturing industry, it can handle waste materials such as steel shavings generated during metal processing. In electronic and electrical enterprises, aluminum foil manufacturing enterprises, etc., scrap metal balers are also used to package aluminum foil, electrical housings, aluminum profiles, etc.

IV. Development trend: Continuous innovation in line with the needs of the times

(I) High speed and high efficiency

Improving work efficiency and reducing production costs are important directions for development. In the future, scrap metal balers will continue to optimize their design, improve packaging speed and compression force, and process more scrap metal in a shorter time.

(II) Intelligent upgrade

With the development of microelectronics technology, scrap metal balers will move towards automation and intelligence. Equipped with an automatic diagnosis system, it can monitor the operating status of the equipment in real time, detect potential faults in advance and pre-process them; it can automatically adjust the packaging parameters according to the material and shape of the scrap metal to achieve intelligent operation.

(III) Green Environmental Protection

Pay more attention to energy conservation and environmental protection, reduce energy consumption by optimizing the hydraulic system design; reduce noise and pollutant emissions during equipment operation, meet environmental protection requirements, and promote sustainable development.

Scrap metal baler machine plays an indispensable role in the field of metal recycling. Its efficient working performance and continuous development trend will make greater contributions to resource recycling and environmental protection.