With growing global environmental awareness and the challenge of resource depletion, the scrap metal recycling industry is facing unprecedented development opportunities. In this era of rapid change, the importance of scrap metal recycling machines, as core technical equipment, is self-evident. They are not only the key to achieving resource recycling, but also a powerful engine driving the entire industry towards efficiency, automation, and intelligence.

Core Technical Principles of Scrap Metal Recycling Machines

A scrap metal recycling machine is not a single piece of equipment, but rather a system integrated with multiple functional modules. Its core function is to transform scrap metals of varying shapes and complex compositions into high-quality recycled resources suitable for remelting and casting through a series of physical or mechanical processes.

Crushing and shearing: This is the first and most crucial step in scrap metal recycling. Large scrap metals, such as used cars, discarded home appliances, and construction rebar, must first be processed through a crusher or shearer. Shredders use massive impact, squeezing, or shearing forces to break large metal blocks into smaller pieces. Shears use hydraulic or mechanical means to cut long strips or sheets of metal into sizes suitable for subsequent processing. The efficiency of this stage directly determines the throughput of the entire recycling process.

Sorting and Separation: Shredded scrap metal is often a mixture, potentially containing different types of metals (such as iron, aluminum, and copper) as well as non-metallic impurities (such as plastic, rubber, and glass). Efficient sorting technology is key to increasing recycling value. Magnetic separators are the most widely used sorting equipment, using magnetism to separate ferromagnetic metals (such as iron and steel) from non-magnetic metals. For non-magnetic metals, more advanced eddy current separators are required. These use electromagnetic induction to generate eddy currents on the surface of non-ferrous metals, repelling them and separating them from impurities. Air separators and hydraulic separators also separate by density differences, effectively removing lightweight impurities or separating metals of varying densities.

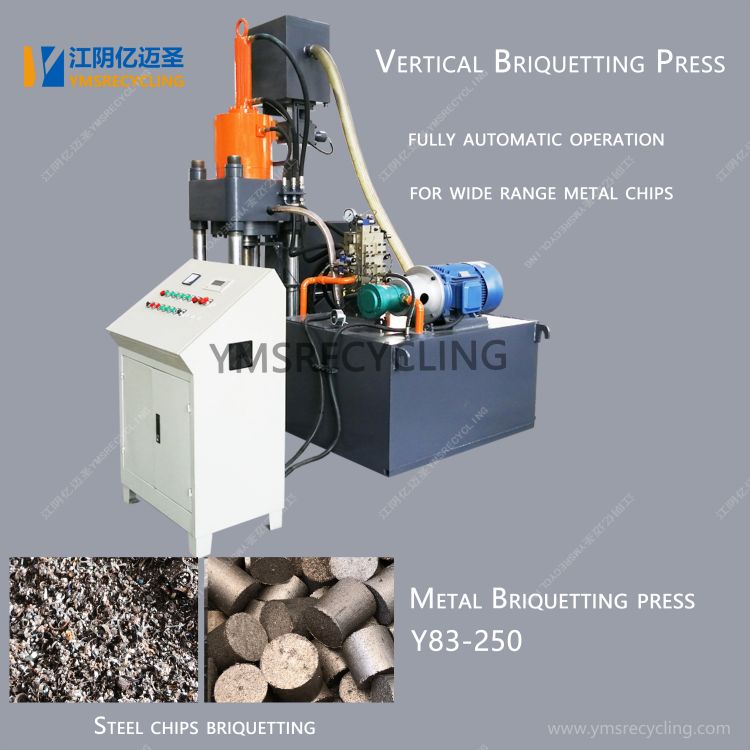

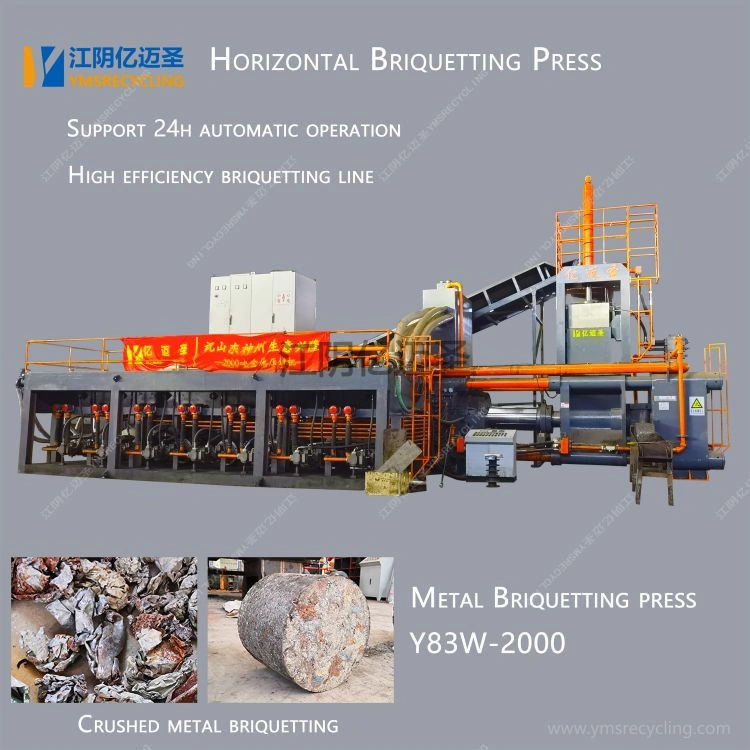

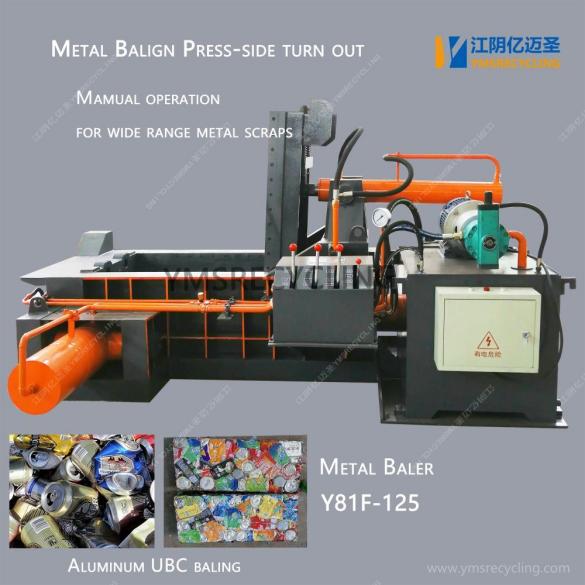

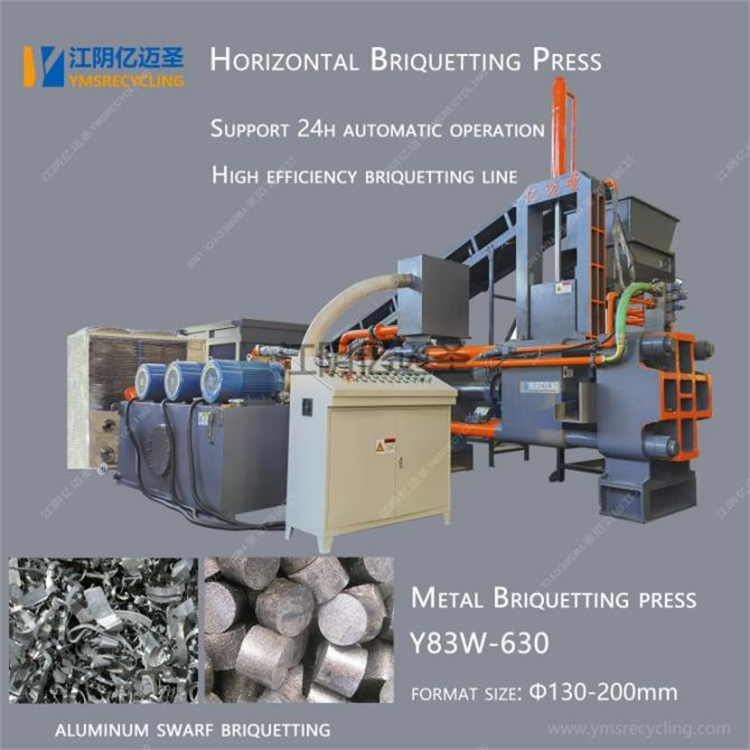

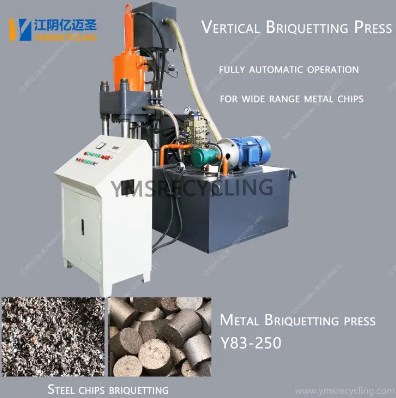

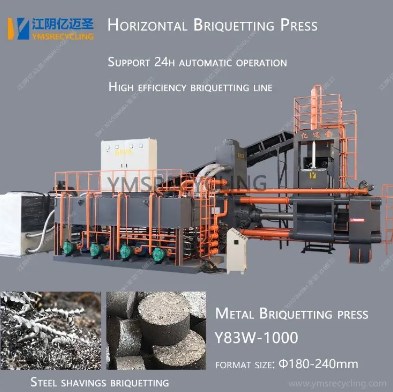

Baling and Briquetting: Pure scrap metal after sorting needs to be baled or briquetting for storage, transportation, and subsequent smelting. Metal balers or briquetting machines compress loose metal chips, wire, or small pieces of metal into high-density blocks or cakes using powerful hydraulic pressure. This not only significantly reduces the volume of the metal, saving storage and transportation costs, but also increases the charge density of the smelting furnace, thereby improving smelting efficiency and reducing energy consumption.

The Future of Intelligent Scrap Metal Recycling Machines

As the wave of Industry 4.0 sweeps the world, scrap metal recycling machines are rapidly developing towards intelligent and automated processes. Traditional recycling machines rely on manual operation and empirical judgment, which limits their efficiency and safety. The new generation of intelligent recycling machines will revolutionize this situation.

Automated Control Systems: Future scrap metal recycling production lines will be fully automated. From automatic material feeding, crushing, sorting, to final baling, the entire process will be centrally coordinated and monitored by a central control system. The application of sensors and machine vision technology enables real-time monitoring of material composition and flow, automatically adjusting equipment operating parameters based on this data to ensure optimal recycling efficiency.

Remote Operation and Maintenance and Fault Diagnosis: Smart recycling machines will feature remote monitoring and diagnostic capabilities. Equipment manufacturers can use cloud platforms to monitor the operating status of user equipment in real time, predict potential failures, and provide remote technical support and software upgrades. This will significantly shorten repair response times, reduce maintenance costs, and ensure long-term stable operation of the equipment.

Big Data and Resource Traceability: Through the large-scale collection and analysis of recycling data, a scrap metal resource big data platform can be established. This not only helps optimize the recycling process but also enables traceability of scrap metal resources. The source, composition, and processing history of each batch of recycled materials will be carefully recorded, forming a complete "identity chain," providing downstream metal manufacturers with more reliable and higher-quality recycled raw materials.

The Profound Impact of Scrap Metal Recycling on Sustainable Development

The widespread use of scrap metal recycling machines not only improves economic benefits but also significantly contributes to social and environmental well-being.

Resource Recycling: Scrap metal is the "mine" of cities. Efficient recycling machines can transform these resources, once considered waste, into valuable raw materials. This directly reduces the need for primary mineral extraction, protects precious Earth resources, and alleviates the pressure of resource depletion.

Energy Conservation and Emission Reduction: Compared to refining metals from ore, recycling scrap metals for smelting significantly reduces energy consumption. For example, recycled aluminum consumes only about 5% of the energy required to produce primary aluminum, and recycled steel consumes far less energy than smelting iron ore. The widespread use of scrap metal recycling machines has made a substantial contribution to global carbon reduction goals.

Environmental Protection: Irregular scrap metal disposal methods, such as indiscriminate dumping and incineration, can cause serious pollution to the soil, water, and air. Modern scrap metal recycling machines, through closed, pollution-free processing processes, effectively prevent secondary environmental pollution. They transform scrap metal into harmless, reusable resources and are a crucial component of building a green, low-carbon circular economy.

A scrap metal recycling machine is more than just a piece of equipment; it is a bridge connecting the past and the future, a ray of hope for resource recycling. With the continuous advancement of technology, future scrap metal recycling machines will surely be more efficient, intelligent and environmentally friendly, contributing to our efforts to build a more sustainable and better world.