In modern manufacturing, the use of metal materials continues to increase, and with it, the amount of scrap metal chips, metal scraps, and processing off-cuts is also growing rapidly. Efficient, environmentally friendly, and economical processing of these metal scraps has become a key focus in the industry. With the increasing adoption of energy conservation, emission reduction, and recycling, scrap metal chip briquetting machines are gradually entering the market and playing an increasingly important role in resource recycling and waste management.

Working Principle and Technical Features of Metal Chip Briquetting Machines

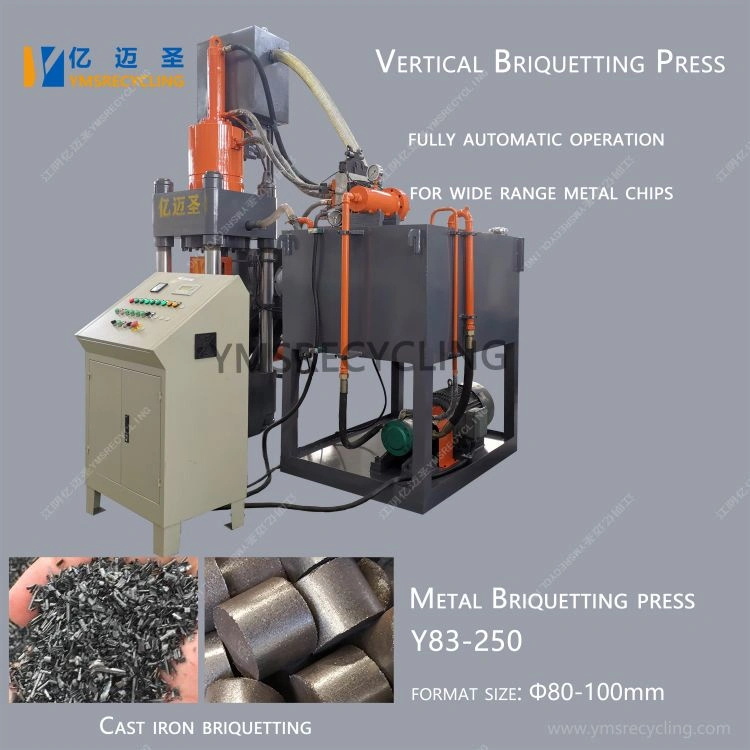

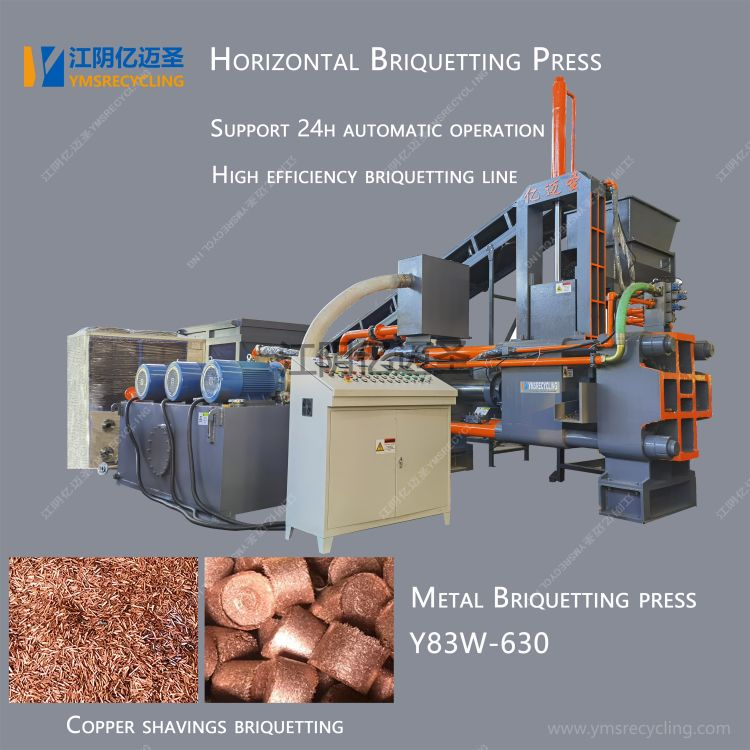

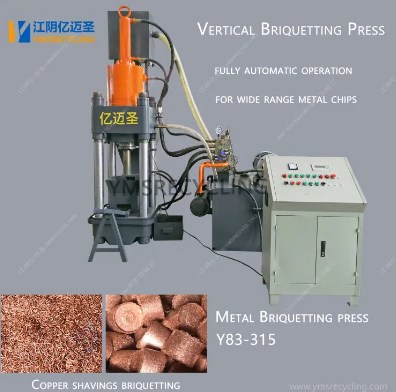

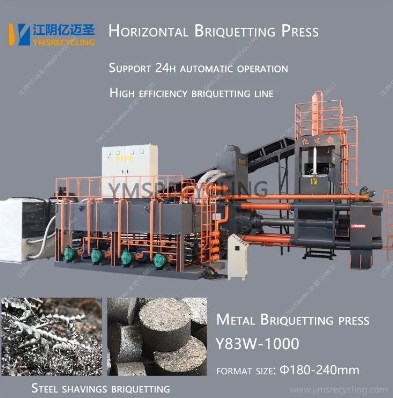

The core function of a scrap metal chip briquetting machine is to compress loose, lightweight, and bulky metal chips into dense blocks under high pressure. This machine, typically powered by a hydraulic system, can quickly achieve high-density compaction of chips, significantly reducing space usage and improving transportation and storage efficiency. Its operating principle primarily revolves around hydraulic cylinder pressure, die forming, and automated control, ensuring stable compaction even when processing scrap materials of varying metal materials and particle sizes.

In terms of technical features, the equipment not only boasts a high compression ratio but also can adjust pressure and mold parameters based on different metal types (such as steel, aluminum, and copper), ensuring that the density and purity of the pressed metal blocks meet recycling requirements. Furthermore, modern scrap metal chip briquetting machines are often equipped with automatic feeding and discharging systems, enabling continuous operation and further improving production efficiency and safety.

Environmental Advantages of Scrap Metal Chips Briquetting Machines

Swarf generated during metal processing often contains oil or coolant, making storage and transportation difficult and potentially polluting the environment. Using a scrap metal chip briquetting machine not only compresses the metal chips but also effectively separates some of the residual liquid during the pressing process, allowing for the drying of the scrap. This reduces the environmental impact of liquid leakage and facilitates subsequent remelting and reuse of the metal.

The significantly reduced volume of the briquetted metal chips allows for higher loading rates during transportation, reducing energy consumption and transportation costs. For companies pursuing green manufacturing and carbon emission control, this type of equipment offers a practical solution, helping them strike a balance between production efficiency and environmental responsibility.

Key Equipment for Improving Metal Recycling Efficiency

With the continuous fluctuation of metal resource prices, the recycling value of scrap metal has become increasingly prominent. The scrap metal chip briquetting machine uses a briquetting process to more efficiently feed scrap metal chips into the smelting process. Compared to loose metal chips, briquetted metal has a higher combustion rate and lower oxidation losses during smelting, effectively increasing metal recovery and reuse value.

In metallurgical companies and metal recycling plants, the use of briquetting machines can significantly improve the stability of raw material feeding and reduce material waste caused by chip flyaways. Furthermore, the briquetted metal blocks have a higher density, allowing them to sink quickly during the smelting process, improving the uniformity and efficiency of the reaction within the furnace. This advantage is particularly prominent in large-scale recycling and batch smelting production.

Market Applications and Future Trends

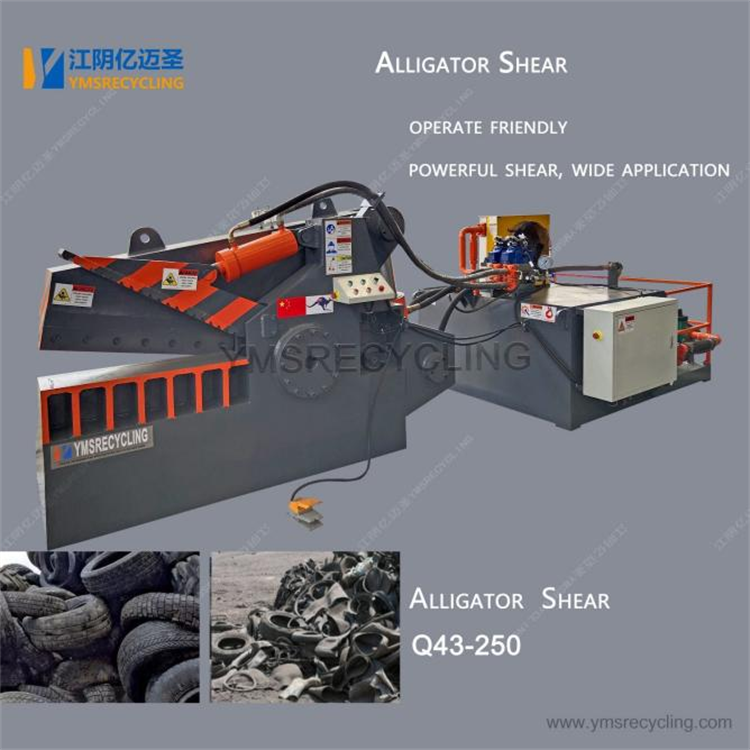

Scrap metal chip briquetting machines are widely used in machinery manufacturing, the automotive industry, aerospace, shipbuilding, and various metal processing companies. These industries generate large quantities of metal chips and powder during their production processes. If not properly handled, this not only wastes resources but also degrades the production environment. By introducing briquetting machines, companies can optimize the entire supply chain, from scrap processing to resource recycling.

Looking ahead, global metal resource shortages and policies promoting green and low-carbon development will further promote the adoption of scrap metal chip briquetting machines. Equipment manufacturers will focus on energy efficiency, intelligent operation, and customized solutions to meet the individual needs of different companies. Furthermore, the integration of artificial intelligence and automated sorting technologies will enable metal chip processing to achieve higher levels of automation and refinement, driving the industry towards sustainable development.

Scrap metal chip briquetting machines are not only key equipment for scrap metal processing but also a crucial embodiment of the circular economy and green manufacturing concepts. By compressing chips, increasing density, and optimizing transportation and recycling efficiency, they provide a practical and feasible path for the reuse of metal resources. Against the backdrop of simultaneous industrial upgrades and environmental protection needs, the application value of this type of equipment will continue to expand, becoming a vital force in promoting efficient, environmentally friendly, and sustainable development in the manufacturing industry.