As the global resource recycling industry accelerates, scrap metal, as a vital recyclable resource, faces significant challenges in its processing efficiency and quality, directly impacting the economic and environmental benefits of the industry chain. With its superior performance, comprehensive technical framework, and wide applicability, the China Supply Scrap Metal Baler Machine has become a highly sought-after key piece of equipment in the international market, providing efficient solutions for the global scrap metal recycling industry.

Core Advantages of China Supply Scrap Metal Balers

During the design and manufacturing process, China Supply Scrap Metal Baler Machines consistently prioritize "efficiency, stability, and energy saving," creating significant advantages that distinguish them from products from other regions. In terms of structural design, these machines typically utilize high-strength steel for their main frames, combined with precision welding techniques to ensure they can withstand the immense pressures associated with handling various types of scrap metal. This effectively prevents deformation or component damage caused by prolonged, high-intensity operation, significantly extending the equipment's service life.

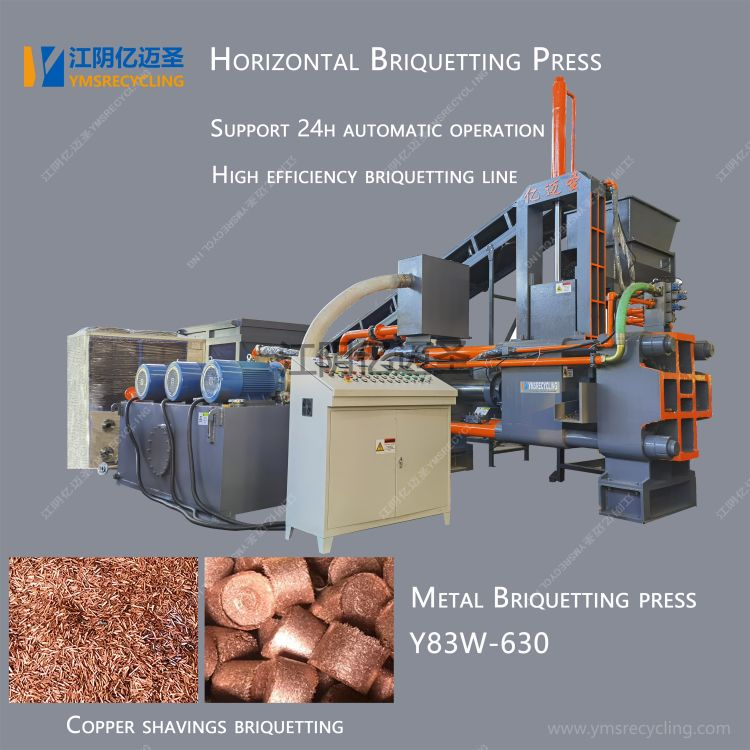

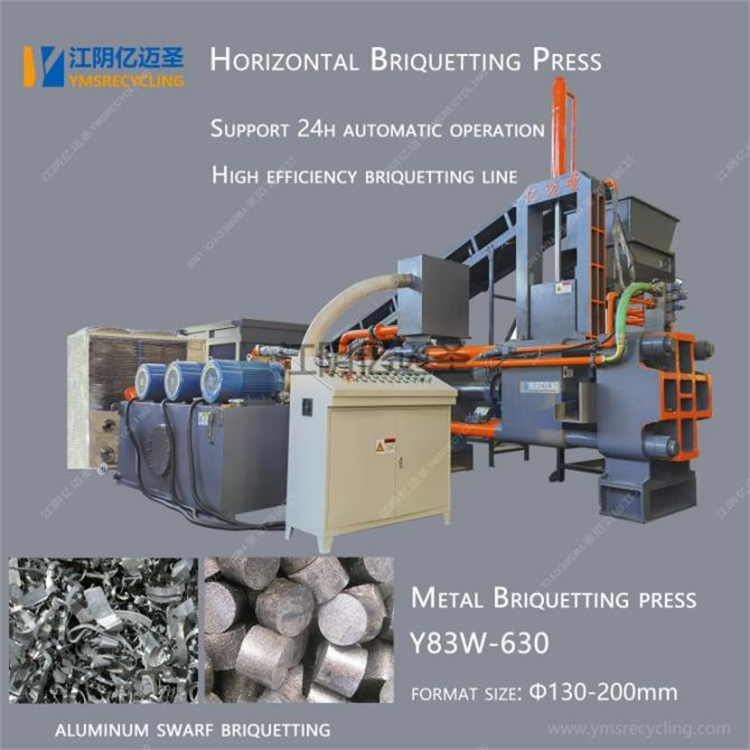

In terms of powertrain, the China Supply Scrap Metal Baler Machine prioritizes a balance between power and energy consumption. By optimizing the hydraulic system design and employing advanced hydraulic pumps and control valves, precise power output control is achieved. This ensures strong pressure when handling heavy scrap metal while reducing energy consumption during light-load operations, achieving energy conservation and environmental protection. Furthermore, the equipment's automated control system is continuously upgraded, enabling continuous operation of the feeding, compression, baling, and discharge stages. This reduces manual intervention, minimizes operational errors, and significantly improves overall processing efficiency.

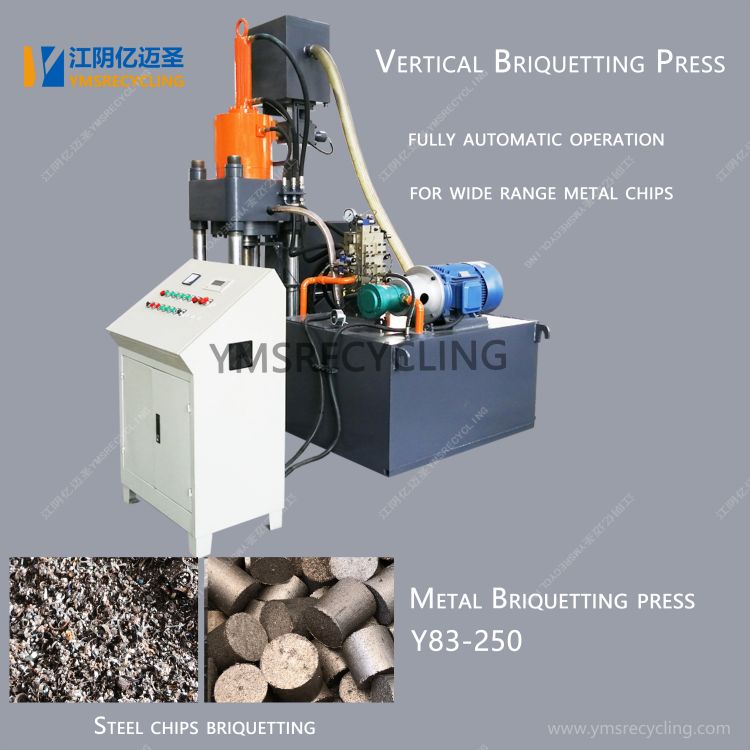

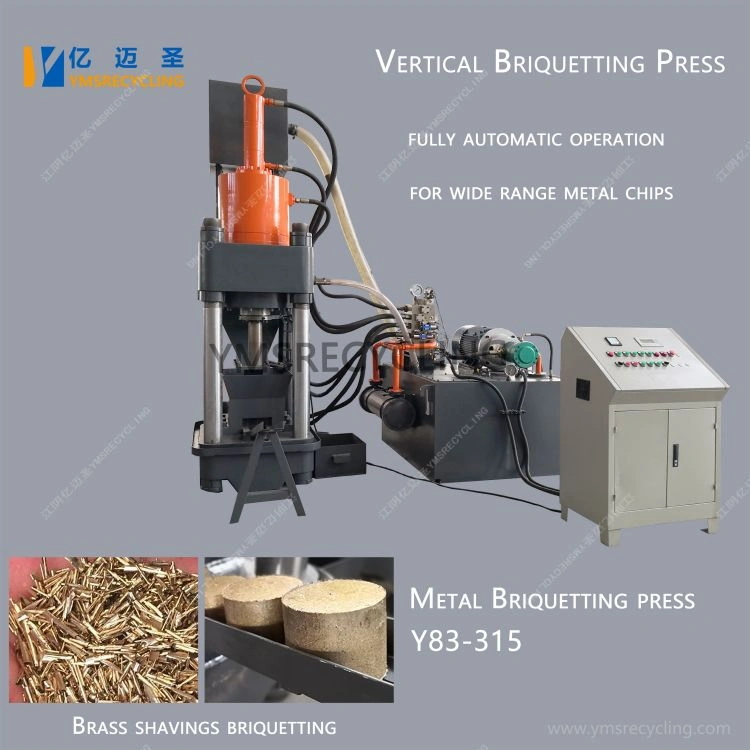

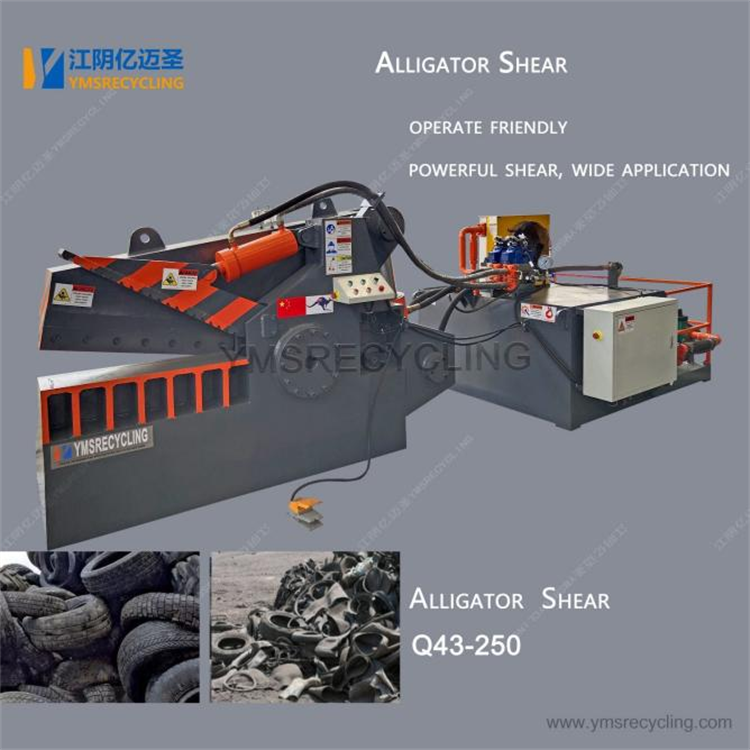

The China supply scrap metal baler machine is highly adaptable and can handle a wide range of scrap metal materials, including scrap steel, scrap aluminum, and scrap copper. Whether in block, flake, or filament form, efficient compression and baling can be achieved by adjusting the machine parameters. The resulting baled metal blocks have a uniform density, making them easier to transport and subsequently melt, saving recycling companies significant transportation costs and storage space.

Technological upgrades drive equipment performance improvements

As the scrap metal recycling industry continues to improve processing standards, China's scrap metal balers are undergoing continuous technological upgrades. In recent years, the application of intelligent technology in balers has become a major highlight. By incorporating IoT technology, the equipment enables remote monitoring and fault diagnosis, allowing operators to monitor the equipment's operating status in real time from their office. If an anomaly occurs, the system automatically issues an alarm and provides troubleshooting suggestions, significantly reducing equipment downtime.

In addition, the integration of automated feeding and sorting systems further enhances the intelligence of scrap metal processing. The equipment automatically adjusts compression parameters based on the type and size of the scrap metal, ensuring consistent baling results and reducing quality fluctuations caused by manual operation. This intelligent upgrade not only improves production efficiency but also reduces labor costs, creating greater profit margins for recycling companies.

Chinese scrap metal balers are also continuously improving their environmental performance. By optimizing the hydraulic oil circulation system, oil consumption and leakage are reduced; a low-noise design reduces noise pollution during operation; and some high-end models are equipped with exhaust gas treatment devices to effectively control dust and harmful gases generated during operation, complying with international environmental standards and meeting the stringent environmental requirements of different regions. A Comprehensive Market Service System Guarantees

While focusing on product quality, Chinese scrap metal baler suppliers have also established a comprehensive market service system to provide comprehensive support to global customers. During the pre-sales phase, suppliers tailor solutions based on specific customer needs, such as processing volume, scrap metal type, and site conditions. They recommend the most suitable equipment model and provide detailed technical specifications and solution descriptions to help customers make the optimal choice.

During the sales phase, suppliers arrange for professional technicians to oversee the installation and commissioning of the equipment, ensuring rapid operational operation. They also provide operational training, detailing the equipment's operating procedures, maintenance points, and safety precautions to ensure operators master its use.

During the post-sales phase, suppliers have established an efficient after-sales service network, promising to respond to customer repair requests within specified timeframes and provide an adequate supply of spare parts. For large-scale projects, suppliers also offer regular on-site inspections to promptly identify and resolve potential equipment issues, ensuring long-term stable operation. This comprehensive service system not only strengthens customer trust in Chinese scrap metal balers but also lays a solid foundation for product market expansion.

China's scrap metal baler machine industry occupies a significant position in the global market thanks to its superior performance, continuous technological innovation, and comprehensive service offering. With the continuous advancement of technology and escalating market demand, China's scrap metal baler industry will continue to play a core role in resource recycling and make greater contributions to promoting global sustainable development.