In the modern metal processing industry, aluminum processing is almost ubiquitous. The resulting aluminum shavings, if not effectively processed, not only waste resources but also pose environmental pollution and safety hazards. The aluminum shavings briquetting machine has emerged as a core piece of equipment for aluminum scrap recycling and reuse. It not only improves the efficiency of storing and transporting aluminum shavings but also provides a stable source of raw materials for aluminum smelting.

Working Principle of the Aluminum Shavings Briquetting Machine

The core of the aluminum shavings briquetting machine lies in the cooperation of a high-pressure hydraulic system and a forming mold. The equipment uses a hydraulic cylinder to provide powerful pressure, compressing loose aluminum shavings into dense aluminum blocks. During this process, the volume of the aluminum shavings is significantly reduced, while the surface tension and inter-particle friction are enhanced, giving the compressed aluminum blocks good structural strength and ease of handling.

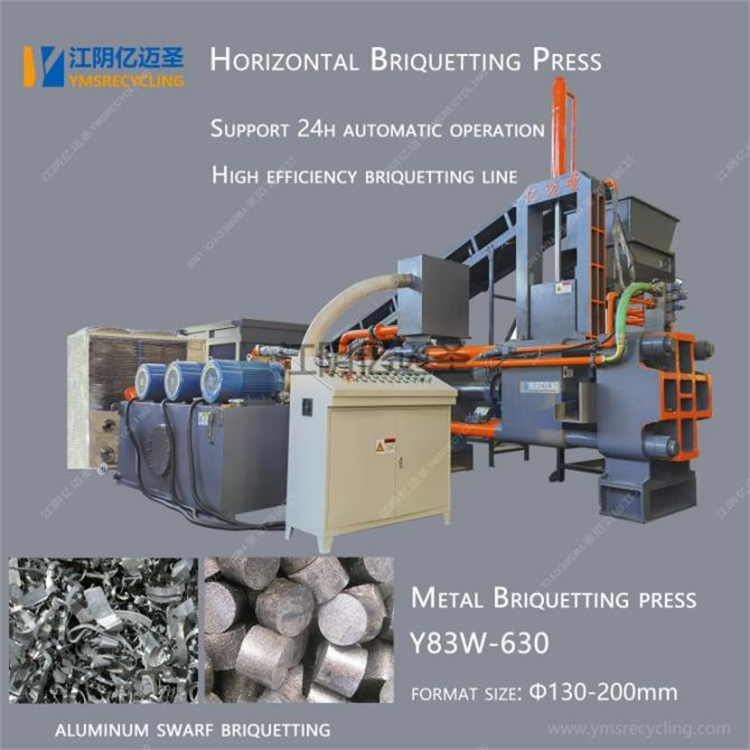

The equipment's workflow typically includes feeding, pressing, block ejection, and cleaning. The feeding system ensures that the aluminum shavings are evenly fed into the pressing chamber, the hydraulic system provides continuous and stable pressure, and the mold design directly determines the shape, size, and compression density of the aluminum blocks. Through precise control of pressure, mold shape, and pressing time, the aluminum shavings briquetting machine can achieve efficient and low-loss briquette production.

Equipment Structure and Key Technologies

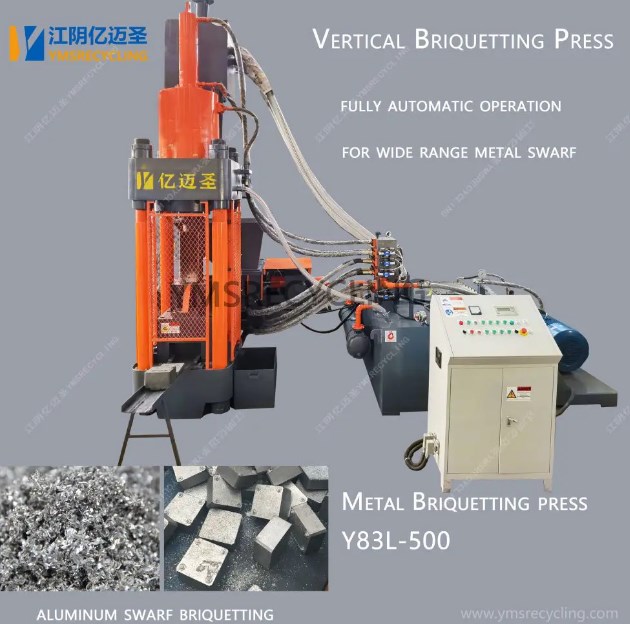

A high-performance aluminum shavings briquetting machine usually consists of a frame, hydraulic system, mold assembly, feeding device, and control system. The frame is made of high-strength steel to ensure the equipment remains stable under high-pressure operation. The hydraulic system is the core component, and its performance directly affects the density and quality of the briquettes. Through advanced hydraulic control technology, the equipment can achieve stable pressing results under different types of aluminum shavings and humidity conditions.

The design of the mold assembly is also crucial. Different shapes and sizes of molds can meet diverse customer needs. The mold material usually uses wear-resistant alloy steel to withstand the friction and impact caused by high-frequency pressing. In terms of the control system, modern aluminum shavings briquetting machines mostly use PLC or touch screen interfaces for automated control, allowing for setting pressure, pressing time, and cycle time, significantly improving production efficiency.

Advantages of the Aluminum Shavings Briquetting Machine

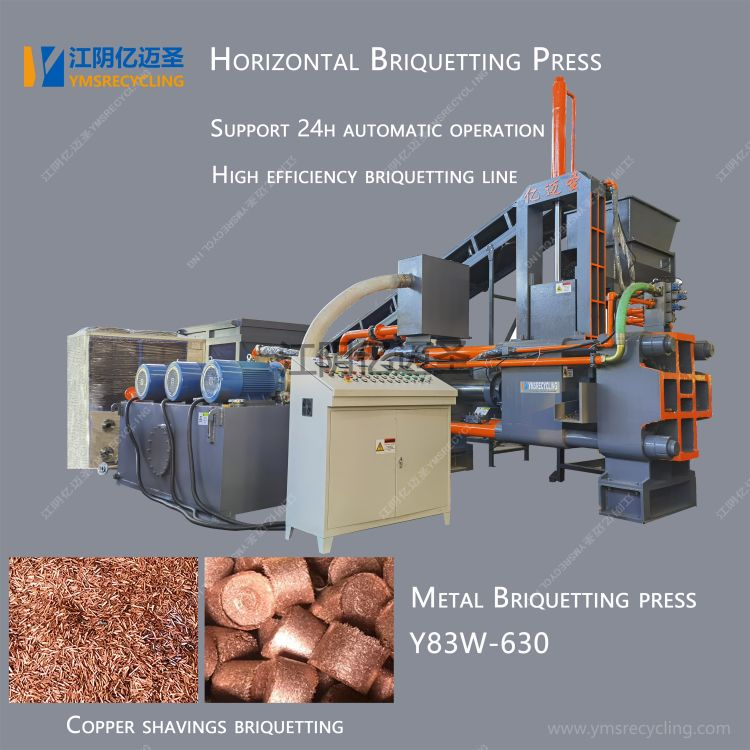

Improving storage and transportation efficiency is one of the biggest advantages of the aluminum shavings briquetting machine. After being compressed into blocks, aluminum chips significantly reduce in volume, making them easier to stack and transport, while also lowering storage costs. Improved smelting efficiency is another significant advantage. The compressed aluminum blocks have high density and uniform shape, allowing them to melt faster during the smelting process, reducing energy consumption and increasing metal recovery rates.

The environmental benefits of the equipment are also outstanding. Loose aluminum chips are prone to scattering during transportation and storage, causing dust pollution. Compressed aluminum chips effectively reduce dust generation, ensuring a safe working environment. The hydraulic compression process does not require the addition of binders or chemical additives, avoiding secondary pollution and achieving green production.

Scope of Application of Aluminum Chip Briquetting Machines

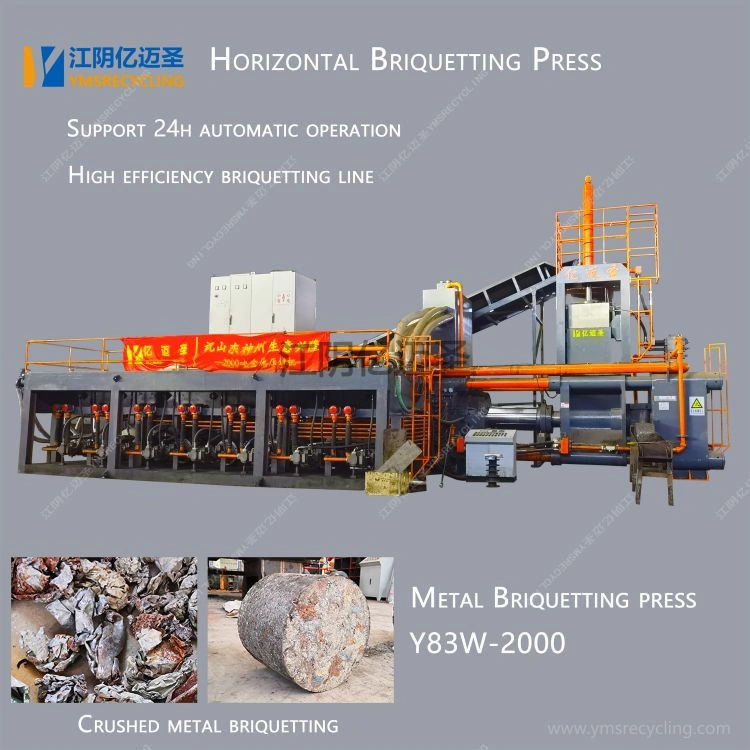

Aluminum chip briquetting machines are not only suitable for recycling production waste from aluminum processing companies but are also widely used in aluminum smelters, recycling companies, and recycled aluminum processing enterprises. Whether wet or dry aluminum chips, different particle sizes can be effectively compressed by adjusting the pressure and mold. The equipment is also flexible in adapting to different production scales, from small processing workshops to large industrial bases, achieving efficient operation.

Key Factors in Choosing an Aluminum Chip Briquetting Machine

When selecting an aluminum chip briquetting machine, key factors to consider include the performance of the hydraulic system, mold design, compression capacity, and automation level. The stability of the hydraulic system directly affects the density and consistency of the aluminum blocks; the wear resistance and reasonable design of the mold determine the shape and output efficiency of the blocks; and highly automated equipment can achieve unattended operation, saving labor costs.

Furthermore, after-sales service and spare parts supply are also important criteria for evaluating the quality of the equipment. High-quality aluminum chip briquetting machine manufacturers usually provide comprehensive technical support and long-term spare parts supply to ensure the equipment operates stably for a long time, maximizing the return on investment.

The Practical Value of Aluminum Chip Briquetting Machines in Production

The aluminum chip briquetting machine is not just a piece of equipment, but a powerful tool for enterprises to achieve resource recycling. Through the efficient briquetting of aluminum chips, it not only saves storage space and transportation costs but also improves smelting efficiency, reduces energy consumption and environmental pollution. For enterprises, it directly reflects the comprehensive value of production cost control, resource management, and environmental responsibility.

In addition, with the development of the recycled aluminum industry and the popularization of green manufacturing concepts, the application value of aluminum chip briquetting machines will further increase. The equipment not only helps companies achieve economic benefits but also supports sustainable development strategies, providing strong support for green production.

FAQ

Q1: Can the aluminum chip briquetting machine process wet aluminum chips?

A1: Yes. Modern aluminum chip briquetting machines, through the adjustment of the hydraulic system and mold design, can effectively process wet aluminum chips and ensure the density and molding quality of the briquettes.

Q2: Are the pressed aluminum blocks suitable for smelting?

A2: Yes. The briquettes have high density and uniform structure, allowing them to melt quickly during the smelting process, improving metal recycling efficiency.

Q3: Does the equipment require a dedicated operator?

A3: Not necessarily. Highly automated aluminum chip briquetting machines are equipped with a PLC control system and touch screen interface, enabling unattended operation and improving production efficiency.

Q4: Does the aluminum chip briquetting machine have a long service life?

A4: The service life depends on the equipment quality and maintenance. High-quality models use wear-resistant molds and a stable hydraulic system, ensuring long-term stable operation.

Q5: Is the equipment maintenance complicated?

A5: Maintenance is relatively simple. Regular checks of the hydraulic oil, replacement of wear parts, and cleaning of the molds are sufficient to maintain stable operation of the equipment.