In the development of modern industry, scrap metal recycling has become an indispensable and important link. Scrap metal processing not only effectively saves resources but also reduces environmental pollution, contributing to sustainable development. In this process, scrap metal processing equipment plays a crucial role. From the initial collection and dismantling of scrap metal to the subsequent fine sorting and reprocessing, various efficient scrap metal processing equipment has become the core driving force for the development of the metal recycling industry.

Diversity and Functionality of Scrap Metal Processing Equipment

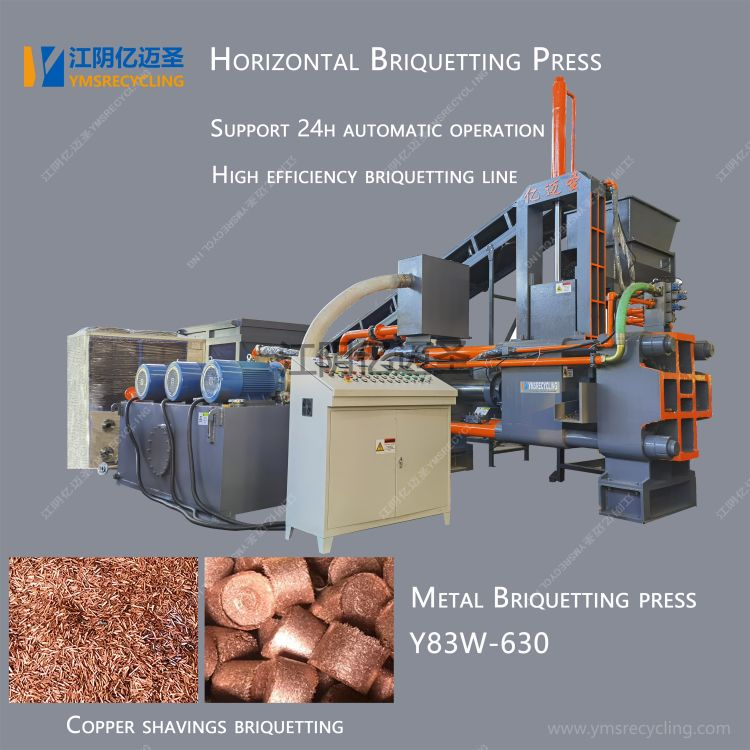

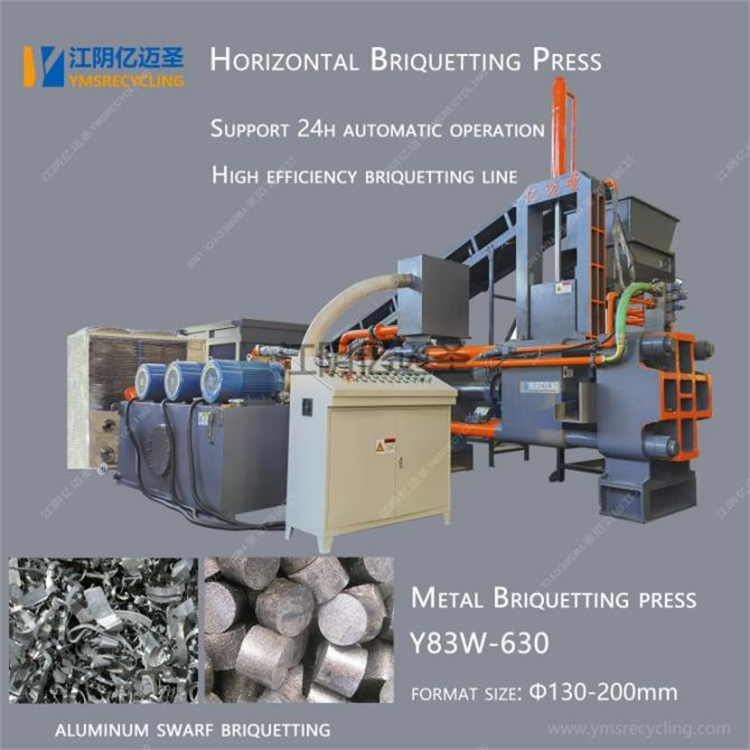

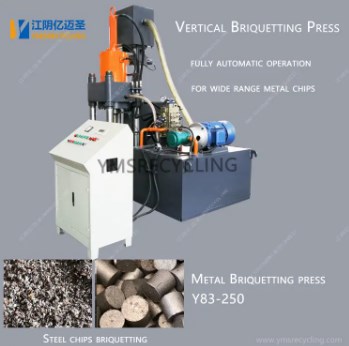

Scrap metal processing equipment comes in a wide variety, each with its unique working principle and function. These devices are designed for efficiency, energy saving, and environmental protection, aiming to improve the metal recovery rate during the recycling process while minimizing energy consumption and environmental impact. Common scrap metal processing equipment includes metal shredders, hydraulic shears, balers, and magnetic separation equipment, each optimized for different types of scrap metal to meet various recycling needs.

Metal shredders are one of the most basic pieces of equipment, primarily used for shredding various scrap metal materials, such as废旧 cars, household appliances, and metal scrap. Through multiple shredding processes, the scrap metal is broken down into smaller pieces, facilitating subsequent sorting and processing. Hydraulic shears, on the other hand, can cut larger metal objects, such as scrap rebar and large metal structures. Through efficient shearing, the volume of scrap metal is significantly reduced, making further processing easier.

The role of magnetic separation equipment in scrap metal processing is also crucial. It mainly utilizes magnetic separation technology to separate ferrous components from non-ferrous metals in scrap metal, achieving precise sorting. This not only improves the recovery rate but also reduces resource waste during the processing.

High Efficiency and Environmental Protection: Core Requirements for Scrap Metal Processing Equipment

With the increasing awareness of environmental protection and resource conservation, the design and application of scrap metal processing equipment are trending towards high efficiency and environmental friendliness. Equipment that efficiently processes scrap metal can not only significantly improve work efficiency but also reduce energy consumption and minimize air, water, and noise pollution. The concept of green manufacturing has become the mainstream of the scrap metal recycling industry.

Among these, reducing energy consumption is a key point in equipment design. In the scrap metal processing process, the high energy consumption and low efficiency of traditional equipment are often pain points in the industry. Modern scrap metal processing equipment, through optimized design and the use of advanced motors and power systems, reduces energy waste. Taking crushers as an example, modern crushers generally use high-efficiency motors and high-quality cutting tool materials, significantly reducing energy consumption while ensuring crushing efficiency.

In addition to reducing energy consumption, improving material recovery rates is also a key objective for scrap metal processing equipment. With continuous technological advancements, the precision and sorting capabilities of the equipment have gradually improved, allowing for more accurate separation of different types of metals and maximizing the recovery of valuable metals. The application of magnetic separation technology, for example, can greatly increase the recovery rate of non-ferrous metals and precious metals from scrap metal while ensuring high efficiency.

Automation Technology Leads the Development Direction of Scrap Metal Processing Equipment

With the rapid development of industrial automation technology, scrap metal processing equipment is also moving towards intelligence and automation. The introduction of intelligent control systems not only improves production efficiency but also makes the scrap metal processing process more precise and controllable. Through advanced PLC control systems, the operating status of the equipment can be monitored in real time, ensuring the stability and efficiency of equipment operation.

For example, modern scrap metal crushers are equipped with intelligent monitoring systems that can detect the operating status of the equipment in real time and automatically adjust operating parameters to ensure that the equipment is always in the optimal operating state. For large-scale scrap metal processing equipment, the application of remote control and automated monitoring systems greatly reduces the risks and costs of manual operation and improves overall production efficiency.

Widespread Application of Scrap Metal Processing Equipment in Different Industries

The application of scrap metal processing equipment is not limited to the scrap metal recycling industry; it also plays an important role in many industrial fields. For example, industries such as end-of-life vehicle recycling, household appliance recycling, and construction waste treatment all rely on this equipment to improve the efficiency and quality of metal recycling.

In the end-of-life vehicle recycling industry, with the rapid development of the automotive industry, the number of scrapped vehicles is increasing year by year. End-of-life vehicles contain a large amount of metal materials, including steel, aluminum, and copper, which have extremely high recycling value. Scrap metal processing equipment, such as hydraulic shears and metal crushers, plays a crucial role in this process, enabling the dismantling, crushing, and cutting of end-of-life vehicles, laying the foundation for subsequent metal sorting and recycling.

In the construction industry, construction waste also contains a large amount of recyclable metals. Through metal scrap processing equipment, these metals can be efficiently sorted and recycled, reducing resource waste, lowering production costs, and promoting the development of a circular economy.

FAQ

1. What are the main types of metal scrap processing equipment?

Metal scrap processing equipment mainly includes metal shredders, hydraulic shears, balers, magnetic separation equipment, etc. Each type of equipment is optimized for different types of scrap metal to meet recycling needs.

2. How can the working efficiency of metal scrap processing equipment be improved?

The working efficiency of metal scrap processing equipment is continuously improved through the use of high-efficiency motors, optimized designs, and intelligent control systems. Reducing energy consumption and environmental pollution are also key to improving efficiency.

3. What are the environmental impacts of metal scrap processing equipment?

Modern metal scrap processing equipment focuses on environmental protection, using advanced technologies and materials to reduce energy consumption, exhaust emissions, wastewater, and noise pollution, meeting the requirements of green manufacturing.

4. What are the advantages of intelligent metal scrap processing equipment?

Intelligent equipment can achieve real-time monitoring, automatic adjustment of working status, and data analysis functions, which not only improves production efficiency but also reduces manual intervention and lowers maintenance costs.

5. What are the market prospects for metal scrap processing equipment?

With the continuous strengthening of resource recycling and environmental protection regulations, the market demand for metal scrap processing equipment will continue to grow. Intelligence, automation, and energy efficiency will be the main trends in future equipment development.