In modern industry and environmental protection, scrap metal recycling has become a crucial part of resource recycling. Scrap metal recycling machines, as core equipment for scrap metal processing, not only play a key role in the efficiency of waste recycling but also demonstrate irreplaceable value in terms of environmental protection and economic benefits. With technological advancements, these machines are continuously optimized in structural design, processing capacity, and intelligent operation, providing brand-new solutions for the metal recycling industry.

Efficient Separation and Recycling: The Core Technology of the Equipment

The core of scrap metal recycling lies in efficient separation and reuse. Modern scrap metal recycling machines achieve rapid sorting and processing of metals through various technological means. The equipment typically employs advanced crushing systems to crush large pieces of scrap metal to a size suitable for subsequent processing, and combines technologies such as magnetic separation and eddy current separation to achieve efficient separation of non-ferrous and ferrous metals. This technology not only guarantees metal purity but also significantly improves the material recovery rate.

The introduction of automated control systems allows the equipment to automatically adjust the sorting strategy based on the type of metal and material characteristics, reducing the need for manual intervention and improving operational stability and safety. This intelligent sorting method can effectively reduce energy consumption while maintaining high recycling efficiency in actual production.

Structural Optimization and Durability Design

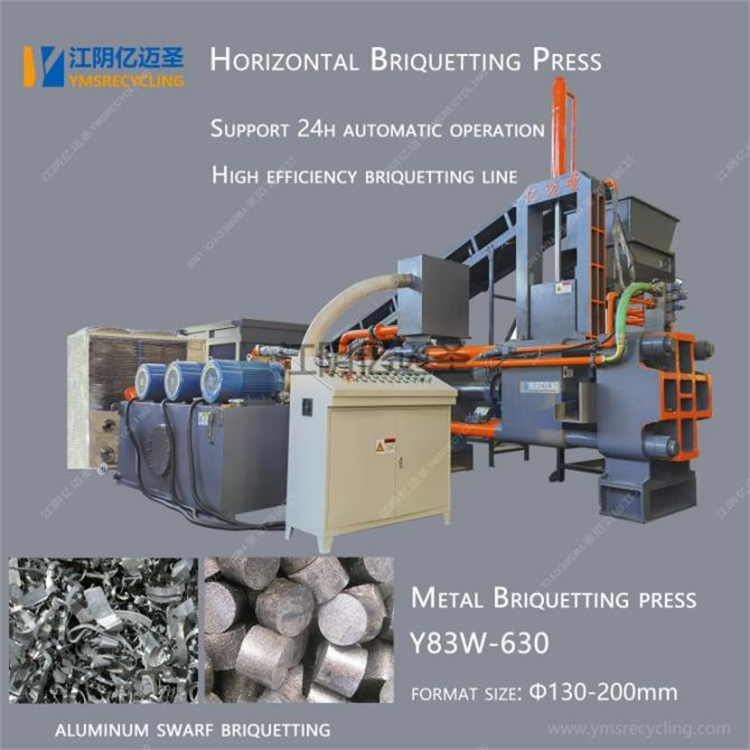

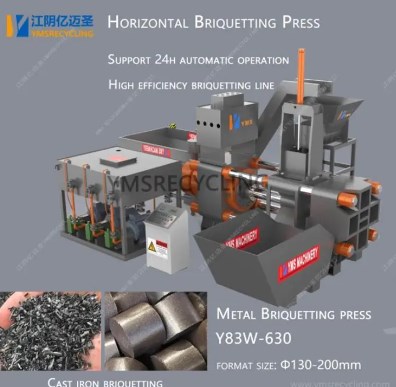

Scrap metal recycling machines also have significant features in their structural design. High-strength steel frame structures, wear-resistant crushing plates, and optimized transmission systems enable the equipment to maintain stable performance even under long-term operation. At the same time, to adapt to the processing of different types of scrap metal, the equipment usually adopts a modular design, allowing users to flexibly configure the crushing, sorting, and conveying systems according to their needs, achieving efficient integration of the overall operation process.

Durability design is not only reflected in the mechanical structure but also in the protection of core components. For example, wear parts use high-wear-resistant materials to reduce the cost of frequent replacement; key bearings and motors are equipped with high-precision protection systems to ensure the safety and stability of the equipment under high-load operation.

Intelligent Operation and Energy-Saving Advantages

In modern industrial applications, scrap metal recycling machines are increasingly moving towards intelligent and automated operation. The equipment is equipped with advanced control panels and monitoring systems that can monitor the operating status, load conditions, and sorting efficiency in real time, and automatically adjust operating parameters based on the data. This intelligent control not only improves production efficiency but also prevents potential failures and extends the service life of the equipment.

Energy saving is an important consideration in equipment design. By optimizing power transmission and workflow, modern scrap metal recycling machines reduce energy consumption during operation, achieving high-efficiency processing while minimizing electricity and resource consumption. The combination of energy-saving design and environmental protection concepts makes the equipment more economically viable in industrial recycling.

Dual Guarantee of Safety and Environmental Protection

In the scrap metal recycling process, operational safety and environmental standards are equally crucial. Scrap metal recycling machines are designed with comprehensive safety features, including multiple safety switches, emergency stop systems, and protective covers, ensuring that operators are protected from potential hazards during production. At the same time, the equipment incorporates optimized designs for dust and noise control, such as enclosed crushing systems and high-efficiency dust removal equipment, effectively reducing environmental impact.

The environmental advantages are not only reflected in the operation process but also in the quality of the final recycled metal. High-precision sorting technology ensures the purity of the scrap metal, facilitating subsequent smelting or reuse, further achieving resource recycling and environmental protection goals.

Application Flexibility and Easy Maintenance

Another significant advantage of scrap metal recycling machines is their application flexibility. Whether it's scrap metal recycling in steel mills, electronic waste processing, or small-scale scrap collection stations, the equipment can adapt to different needs by adjusting configurations and operating modes. Simultaneously, the modular and intelligent design of the equipment makes daily maintenance and repair more convenient. Users can easily replace core components and upgrade systems, ensuring long-term efficient operation.

The intelligent diagnostic system plays a vital role in this process. By monitoring data in real time, the equipment can provide early warnings of potential malfunctions, reducing unexpected downtime and improving overall production efficiency.

FAQ: Frequently Asked Questions about Scrap Metal Recycling Machines

| Q1: What types of metals are suitable for processing by the scrap metal recycling machine? | The equipment is suitable for the recycling of various ferrous and non-ferrous metals, including steel, copper, aluminum, and other recyclable metals, achieving efficient separation through magnetic separation and eddy current separation. |

| Q2: Does the operation of the equipment require professional personnel? | Although intelligent control reduces the difficulty of operation, it is recommended that personnel with basic equipment operation knowledge manage the equipment to ensure safety and optimal operating conditions. |

| Q3: How is the durability of the equipment guaranteed? | Core components use high-wear-resistant materials, key transmission systems have high-precision protection devices, and the modular design facilitates daily maintenance and parts replacement. |

| Q4: Is the energy consumption high? | Modern scrap metal recycling machines are designed with energy efficiency in mind, significantly reducing electricity and operating costs through optimized transmission systems and automatic adjustment of operating modes. |

| Q5: What are the environmental advantages? | The equipment utilizes a closed crushing system and a high-efficiency dust removal device, effectively controlling dust and noise while ensuring the purity of the recycled metal, thus achieving resource recycling. |