In the modern metal recycling and steel processing industry, the Heavy scrap metal shear machine is no longer just a name for industrial equipment. It represents a combination of high efficiency, precision and environmental protection, and is an indispensable and important equipment in the recycling of metal resources.

The existence of this behemoth means far more than just "cutting". Its working scene is usually in the roaring scrap steel processing plant, the metal screening station before smelting, or in the railway and ship dismantling site, where it undertakes huge shearing tasks. Through high-pressure shearing of high-strength materials such as rails, car frames, large steel plates, and scrap metal structures, the heavy shear machine uses its amazing power to transform the originally uncontrollable waste into regular and easy-to-handle metal blocks or strips, which provides great convenience for subsequent transportation, smelting and remanufacturing.

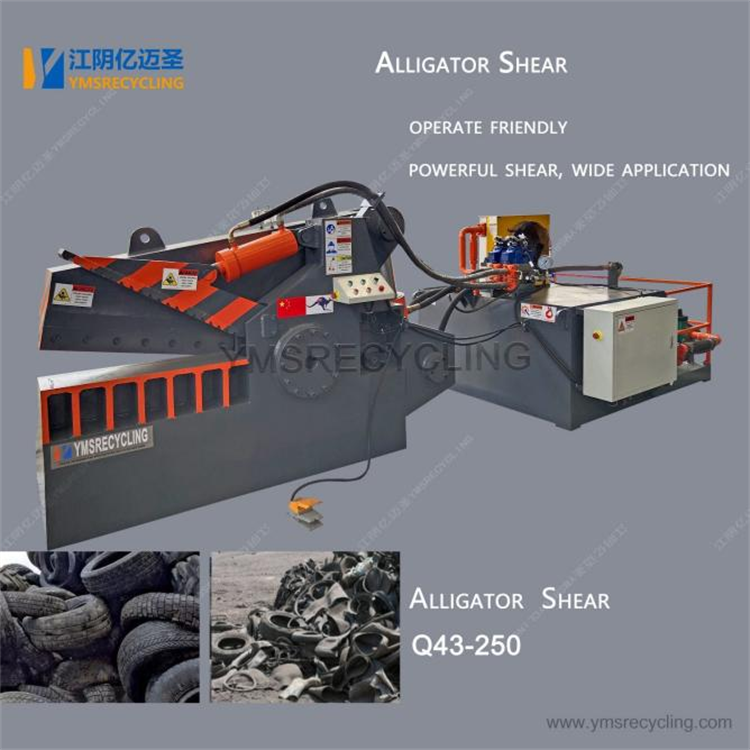

From a technical point of view, the core of the Heavy scrap metal shear machine lies in the coordinated control of its hydraulic system and shearing knife group. Advanced hydraulic technology enables the equipment to generate huge shearing force in a short time, while the knife edge of special alloy material ensures wear resistance and shearing accuracy under long-term high-load operation. Modern high-end models are often equipped with intelligent control systems, which can realize programmed operation and remote monitoring, greatly improving operation safety and operating efficiency.

Another key advantage of this type of shearing machine is its adaptability to diverse waste materials. Compared with traditional flame cutting or manual disassembly, heavy-duty shearing machines can operate directly without complex pre-processing of materials, which not only reduces labor costs, but also reduces energy consumption and carbon emissions, in line with the development trend of green manufacturing and circular economy. In today's pursuit of sustainable development, its environmental protection attributes are particularly valued by all countries.

With the continuous advancement of manufacturing technology and material science, heavy-duty shearing machines have also achieved leapfrog development in structural design. For example, the modular construction concept makes equipment installation and maintenance more convenient, and the movable shearing platform has also come into being, so that the equipment can be more flexibly deployed at different construction sites to meet the needs of rapid on-site processing. This flexibility not only improves the application value of the equipment, but also makes the metal recycling industry respond faster and more efficiently.

The operation of any high-performance equipment is inseparable from the technical support of professional operators. Heavy scrap metal shears have high requirements for operating accuracy and maintenance specifications. From the selection and replacement of hydraulic oil to the adjustment and maintenance of shear blades, every detail directly affects the service life and operation quality of the equipment. For this reason, more and more equipment manufacturers are equipped with complete training plans and after-sales service systems at the time of delivery to ensure that users can maximize the performance of the equipment.

Against the background of the growing global scrap metal recycling market, Heavy scrap metal shear machine plays an increasingly important role. It is not only a tool, but also the core driving force for promoting resource recycling. In the face of the growing demand for industrial waste and metallurgy, it interprets the beauty of the power of industrial machinery with precise and powerful shearing time and time again, and also witnesses the firm steps of the manufacturing industry towards green, efficient and intelligent directions.