In modern industrial society, efficient use of resources has become an important indicator of sustainable development capabilities. With the increasing global attention to environmental protection and resource recycling, the scrap metal recycling industry has also ushered in unprecedented development opportunities. As one of the core equipment in this field, scrap metal baler is gradually changing the traditional way of scrap metal processing. With its high efficiency, environmental protection and intelligent characteristics, it has become an important engine to promote the upgrading of the entire industry.

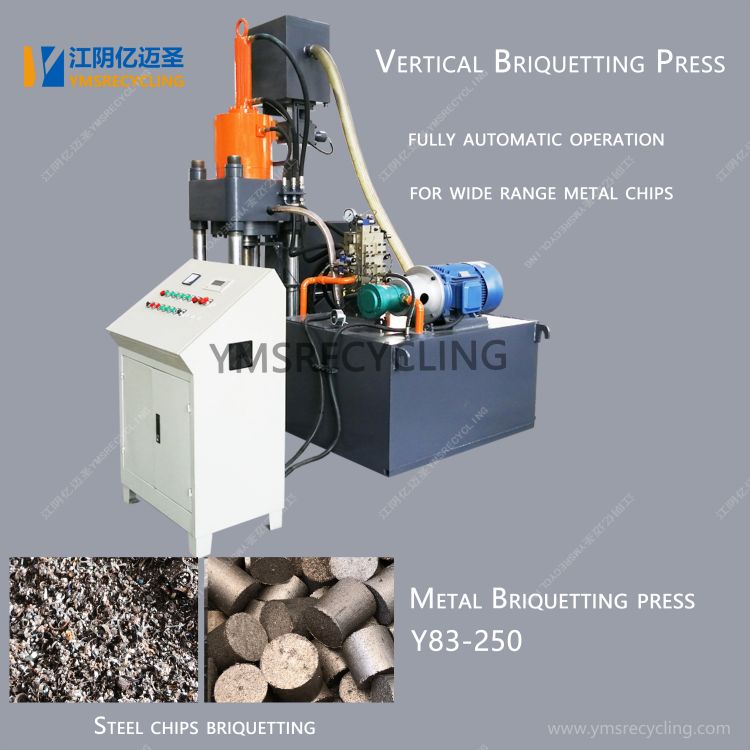

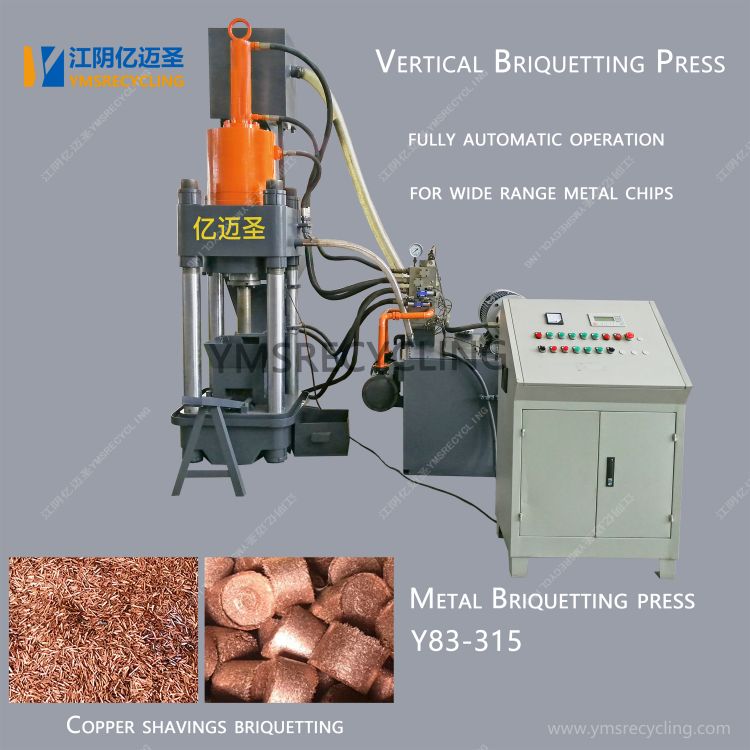

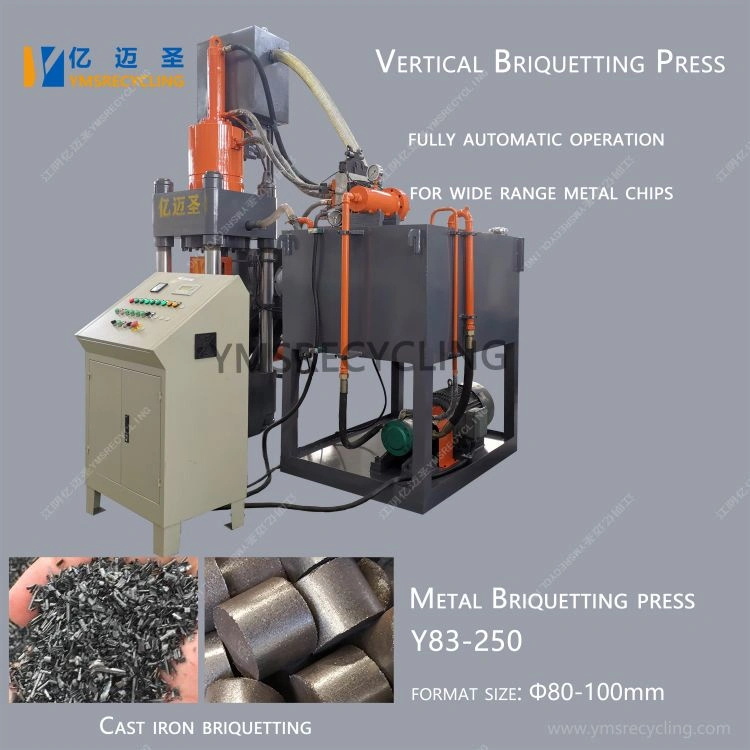

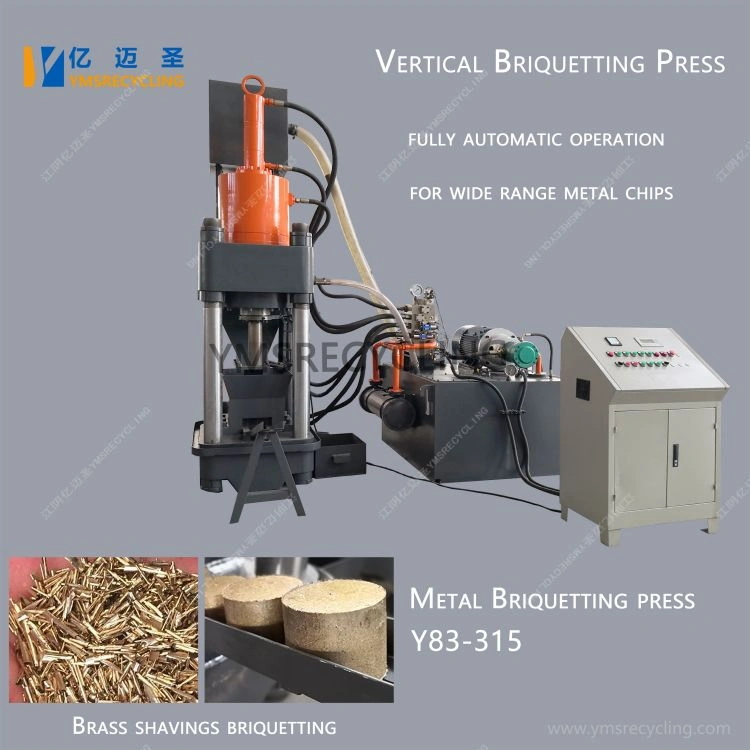

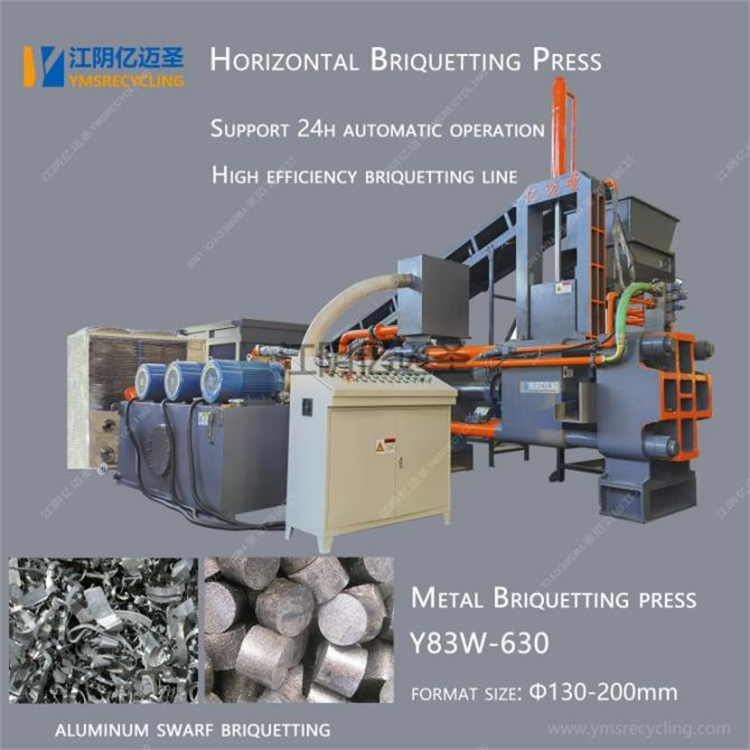

The working principle of scrap metal baler is not complicated. Its core function is to compress large and irregular scrap metal into metal blocks of uniform size and high density through a hydraulic system. This process not only greatly reduces the volume of metal waste, facilitates transportation and storage, but also provides good prerequisites for subsequent smelting and reprocessing. Compared with the previous manual sorting and simple compression processing methods, modern balers have achieved a qualitative leap in work efficiency, operational safety and automation.

In terms of equipment structure, scrap metal baler is usually composed of key components such as hydraulic system, main compression chamber, feeding device, and electronic control system. Among them, the hydraulic system, as the power core, determines the stability of the packaging pressure and the density of the packaging. The modern control system introduces PLC intelligent control technology, which can realize customized processing of scrap metals of different materials and specifications, which not only reduces the intensity of manual operation, but also greatly improves the processing efficiency and equipment life.

Environmental protection is another major advantage of the scrap metal baler. With the increasingly stringent environmental protection regulations of various countries, if the waste metal is not handled properly, it may cause serious pollution to the soil, water and air. The baler provides an effective solution in this regard. Its closed compression design minimizes dust and oil leakage during waste treatment, which meets the current requirements of green development. By using the baler to classify and compress different types of metals, the purity of metal recycling can be improved, the risk of secondary pollution can be reduced, and a solid foundation can be laid for the realization of a true circular economy.

With the acceleration of global industrialization, the types and quantities of various scrap metals are also growing. Traditional balers can no longer meet the increasingly complex processing needs. Therefore, future equipment research and development will place more emphasis on personalization and multi-functional integration. For example, composite baling equipment that can handle a variety of materials such as steel, iron, aluminum, and copper is becoming the mainstream of the market. At the same time, remote monitoring and big data analysis technologies have also been introduced into the scrap metal baling machine system, enabling real-time information such as equipment operating status, production capacity data, and fault diagnosis, providing enterprises with more intelligent operation and maintenance support.