Aluminum shavings are an almost unavoidable component of the metal processing industry's production chain. These seemingly insignificant metal scraps, if improperly handled, not only lead to significant resource waste but can also create safety hazards and environmental impacts due to their accumulation. With the growing global emphasis on green manufacturing and resource recycling, the Aluminum Shavings Briquetting Machine has gradually emerged from the background, becoming a key piece of equipment connecting metal processing and recycling. Its unique technology transforms dispersed aluminum shavings into briquettes that are easily transported, stored, and reprocessed, providing a practical solution for sustainable development in the industry.

Industry Pain Points in Aluminum Shavings Processing and the Core Value of Briquetting Machines

Aluminum, as a lightweight and corrosion-resistant metal material, is widely used in high-end applications such as aerospace, automotive manufacturing, and electronic equipment. During the cutting and grinding processes of aluminum products, large quantities of aluminum shavings of various shapes are generated. These shavings are often mixed with impurities such as cutting fluid and oil, have a low density, and are bulky, making their collection, transportation, and subsequent processing difficult. Traditionally, some companies choose to sell aluminum shavings to recyclers at low prices. This not only results in low economic returns but can also significantly reduce recycling rates due to excessive impurities. Other companies, due to improper storage, easily cause aluminum shavings to oxidize and rust, further reducing their economic value.

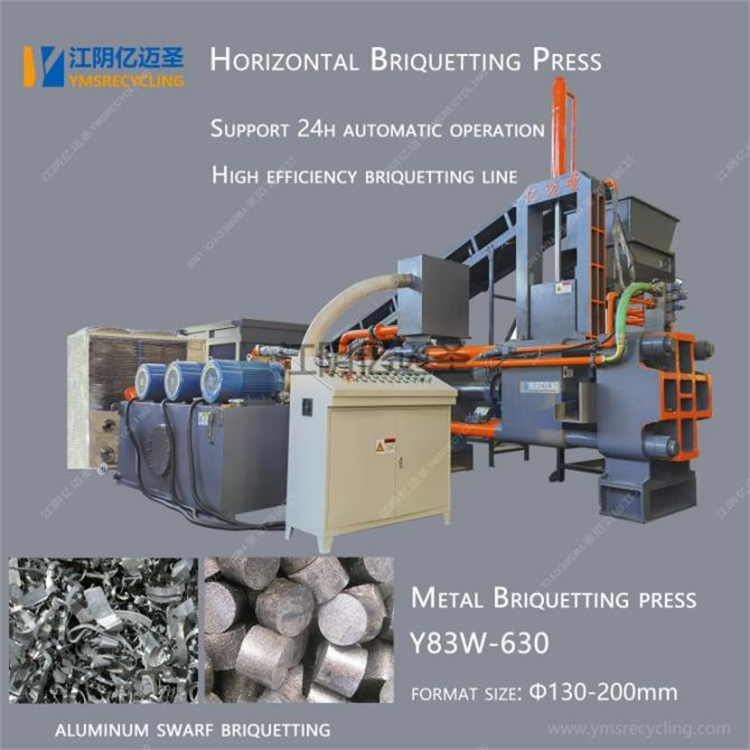

The advent of the aluminum shavings briquetting machine has fundamentally changed this situation. Its core value lies in compressing loose aluminum shavings into blocks with a certain density and strength through mechanical pressure. Briquetting aluminum shavings not only significantly reduces storage space and transportation costs, but also reduces impurity interference during subsequent smelting, improving melting efficiency. More importantly, this processing method closes the loop for aluminum shavings recycling, complying with national energy conservation and emission reduction policies while generating additional economic benefits for companies, achieving both environmental and economic benefits.

Technical Principles and Process Features of the Aluminum Shavings Briquetting Machine

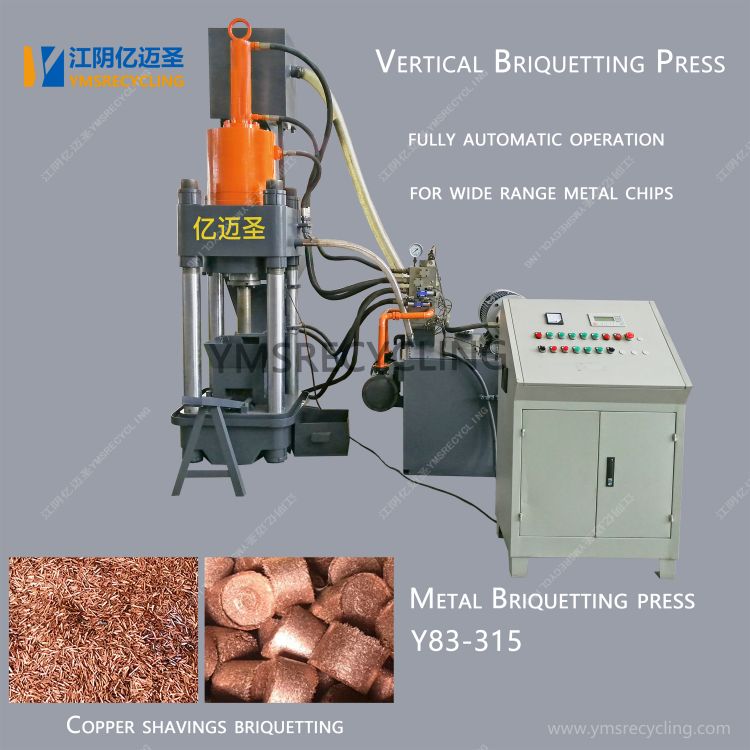

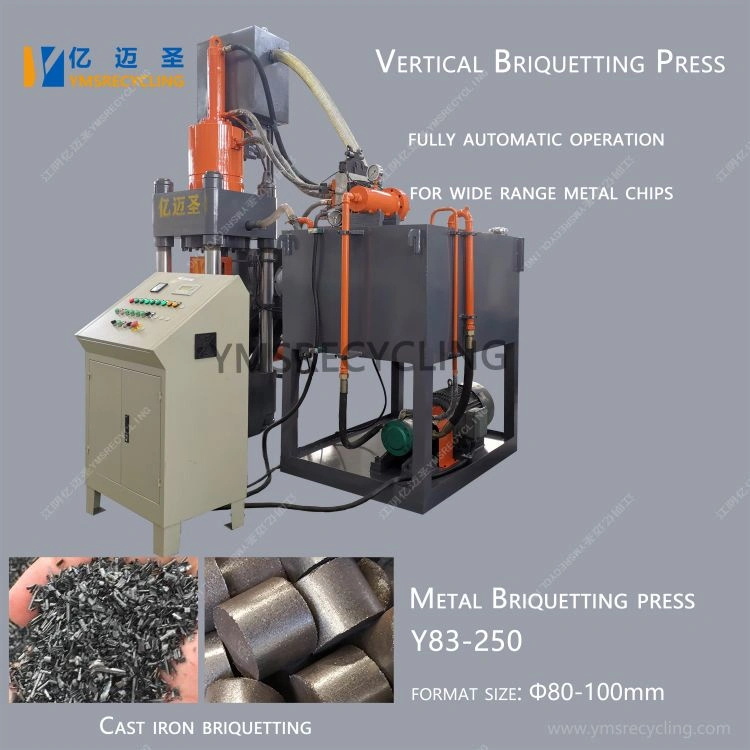

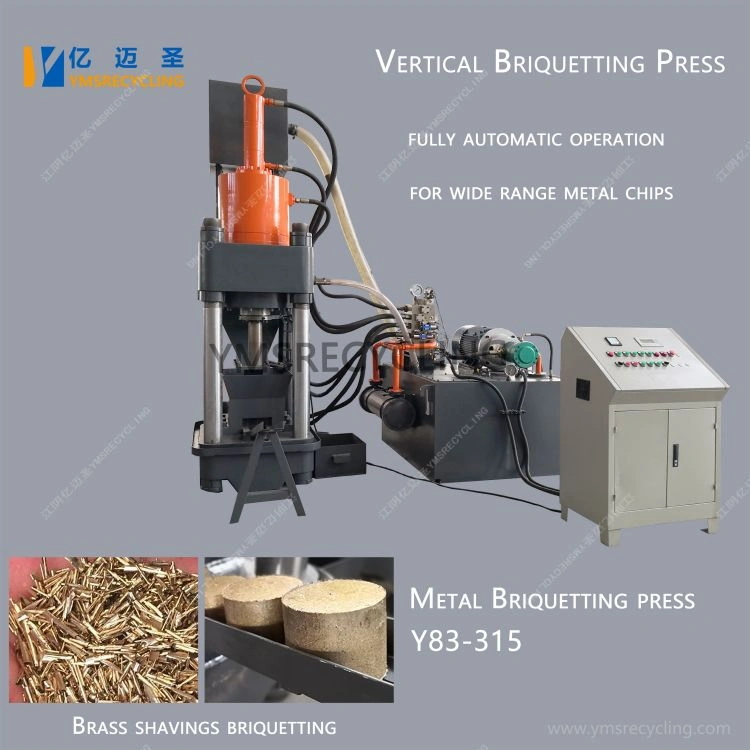

The operating process of the aluminum shavings briquetting machine may appear simple, but it actually requires precise control of material properties and mechanical principles. Its core principle is to compress aluminum chips into a closed mold using the powerful pressure generated by a hydraulic system. Once the aluminum chips are fed into the pressing chamber, the main cylinder piston is driven forward by hydraulic power. The restraining effect of the mold forces air between the chips out, tightly binding the particles together and ultimately forming briquettes with a fixed shape and density.

The design of aluminum chip briquetting machines fully considers the varying characteristics of different aluminum chips. For aluminum chips with a high oil content, some machines are equipped with pre-degreasing devices to reduce the oil content through heating or centrifugation, thereby preventing slippage and loose briquetting during the pressing process. For softer, more sticky aluminum chips, the die feed angle and compression speed are optimized to ensure uniform force distribution. Modern aluminum chip briquetting machines generally utilize intelligent control systems that automatically adjust pressure parameters based on the type and humidity of the chips. This ensures consistent briquetting quality while minimizing energy waste, embodying the integration of high efficiency and energy conservation.

Application Scenarios and Industry Impact of Aluminum Shavings Briquetting Machines

The application scope of aluminum shavings briquetting machines has long transcended metal processing operations, gradually penetrating multiple sectors, including recycling and smelting, forming a complete resource recycling chain. In automotive manufacturing plants, aluminum shavings generated during the processing of large quantities of aluminum parts can be processed by briquetting machines and directly reused in casting production, reducing raw material procurement and transportation costs. In aluminum profile processing plants, the regular shape of the briquetted aluminum shavings makes them easier to mix and melt at smelters, improving the efficiency of recycled aluminum production.

With tightening global resource constraints and increasing environmental protection policies, market demand for aluminum shavings briquetting machines is rapidly growing. They are not only a piece of production equipment, but also a key vehicle for companies to implement sustainable development. By transforming aluminum shavings, once considered "waste," into a reusable resource, aluminum shavings briquetting machines are reshaping resource utilization in the metal processing industry and injecting tangible momentum into the in-depth development of a circular economy. In the future, with the continuous iteration of technology, aluminum chip briquetting machines will become more intelligent and efficient, contributing greater strength to promoting the green transformation of the metal industry.