How to ensure that the hydraulic metal balering press machine maintains efficient and continuous working condition when processing large amounts of metal scrap?

To ensure that the hydraulic metal baler maintains efficient and continuous working conditions when processing large amounts of metal scrap, the following aspects can be considered and implemented:

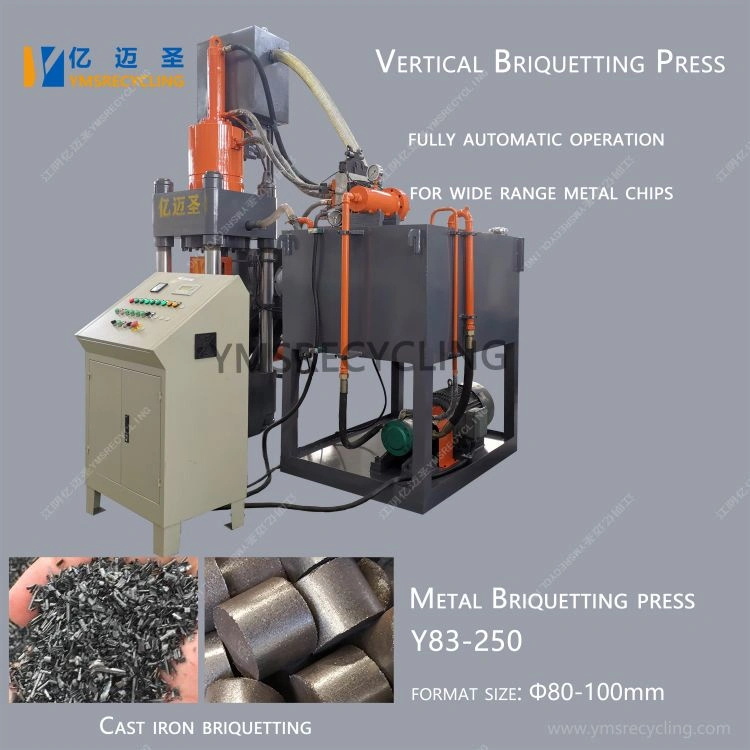

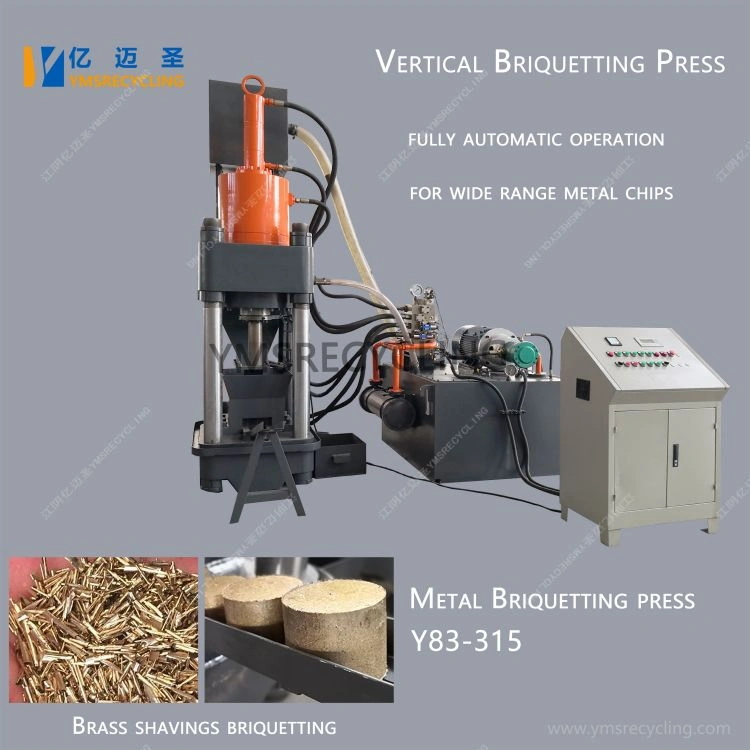

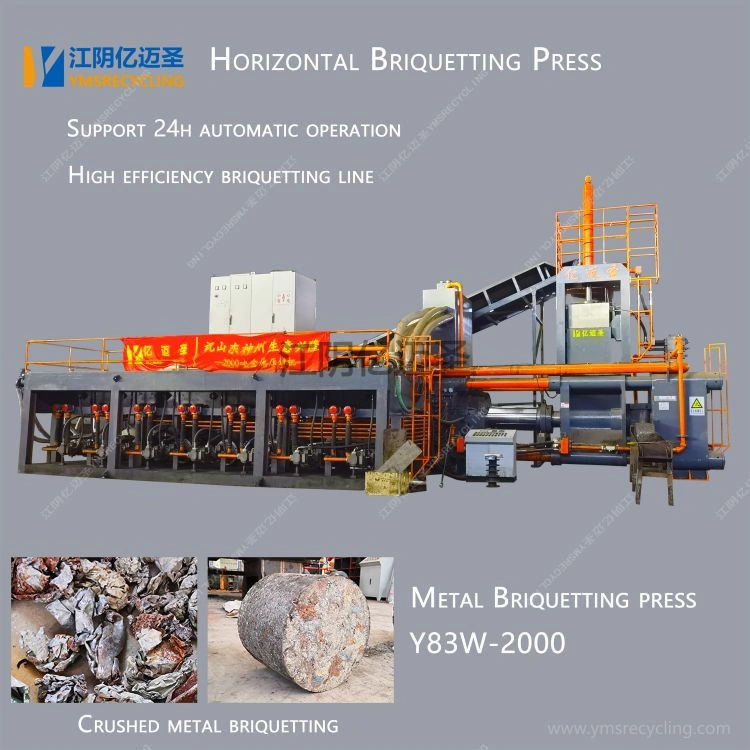

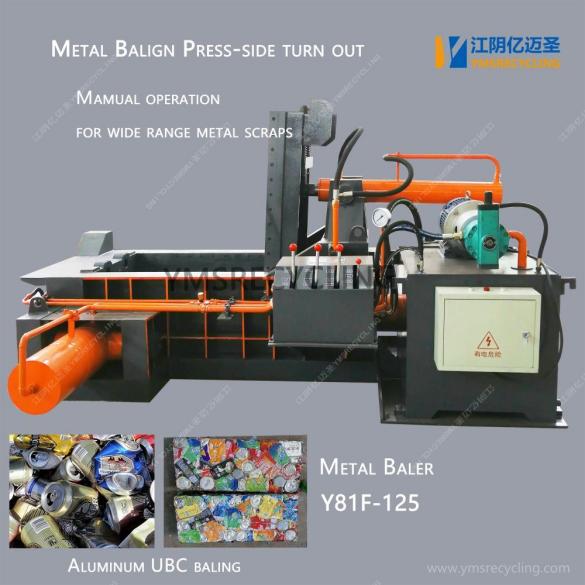

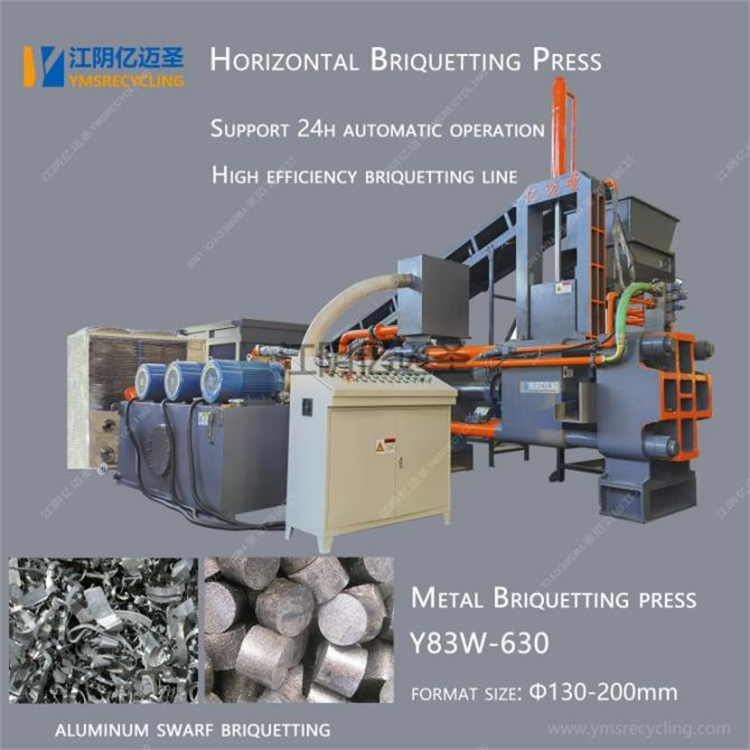

Choose the right equipment model: Choose the right hydraulic metal baler model based on your actual scrap processing needs. Ensure that the equipment’s parameters such as compression capacity, working speed and packaging size match the needs, thereby improving work efficiency.

Optimize the work process: Reasonably plan all aspects of metal scrap placement, compression, packaging and discharging to ensure a smooth and efficient work process. For example, an automatic feeding system can be set up to reduce the time and labor intensity of manual handling.

Regular maintenance and upkeep: Perform regular maintenance and upkeep on the hydraulic metal baler, check the oil level, oil temperature, oil quality and other parameters of the hydraulic system to ensure the normal operation of the equipment. At the same time, wearing parts should be replaced in time to avoid equipment failure affecting work efficiency.

Training operators: Provide professional training to operators to familiarize them with the operation methods and precautions of the equipment. Improving the skill level of operators can reduce the occurrence of misoperations and failures, thereby improving work efficiency.

Adopt intelligent control system: Introduce an intelligent control system to monitor and adjust the working status of the hydraulic metal baler in real time. Through automated control, operations such as quick start, stop, and material change of equipment can be realized to improve work efficiency.

Processing of scraps containing impurities: For metal scraps containing impurities, pre-treatment measures can be used, such as screening, crushing, etc., to remove impurities before compression and packaging. This prevents impurities from causing damage to the equipment while improving compression quality and efficiency.

Spare equipment or parts: When equipment fails or needs repair, there are spare equipment or parts that can be replaced to ensure continuity of work. This avoids work interruptions and losses caused by equipment failure.

Strengthen safety management: Establish a complete safety management system to standardize and manage the operation and maintenance process of hydraulic metal balers. Ensure the safe operation of equipment and the safety and health of operators.