In the modern metal processing industry, aluminum is widely used due to its lightweight, high strength, and excellent ductility. However, the cutting, milling, and stamping processes of aluminum products generate large quantities of aluminum shavings and aluminum powder. If this waste is not effectively handled, it not only wastes resources but also potentially impacts the production environment and workplace safety. The emergence of aluminum shavings briquetting machines provides an efficient, environmentally friendly, and economical solution for the metal recycling industry, becoming a crucial piece of equipment in promoting the development of a circular economy.

Operating Principle and Structure of an Aluminum Shavings Briquetting Machine

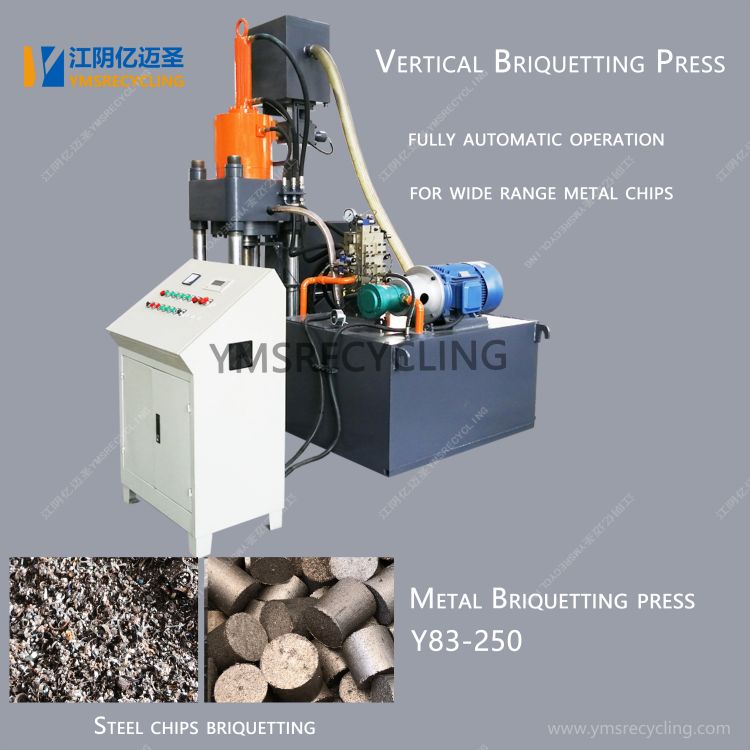

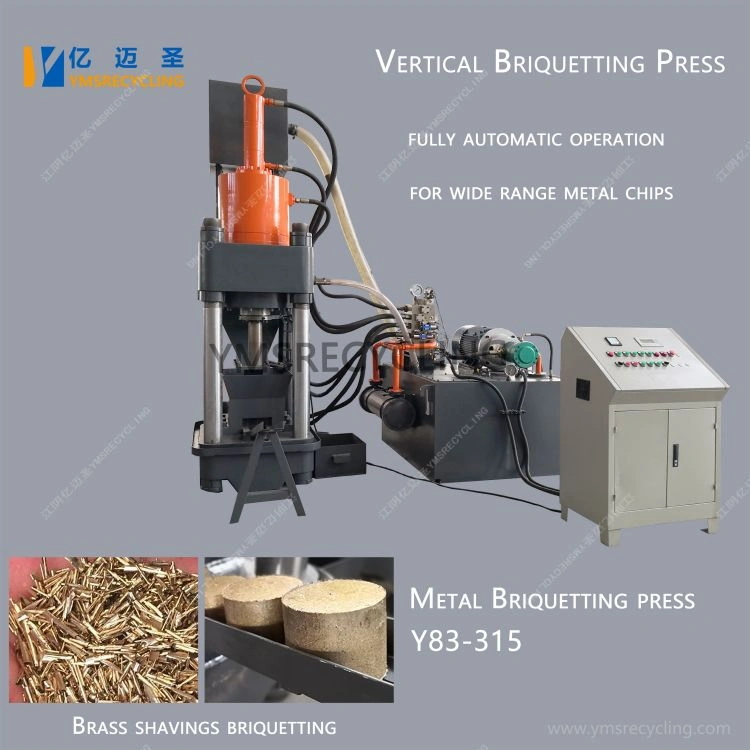

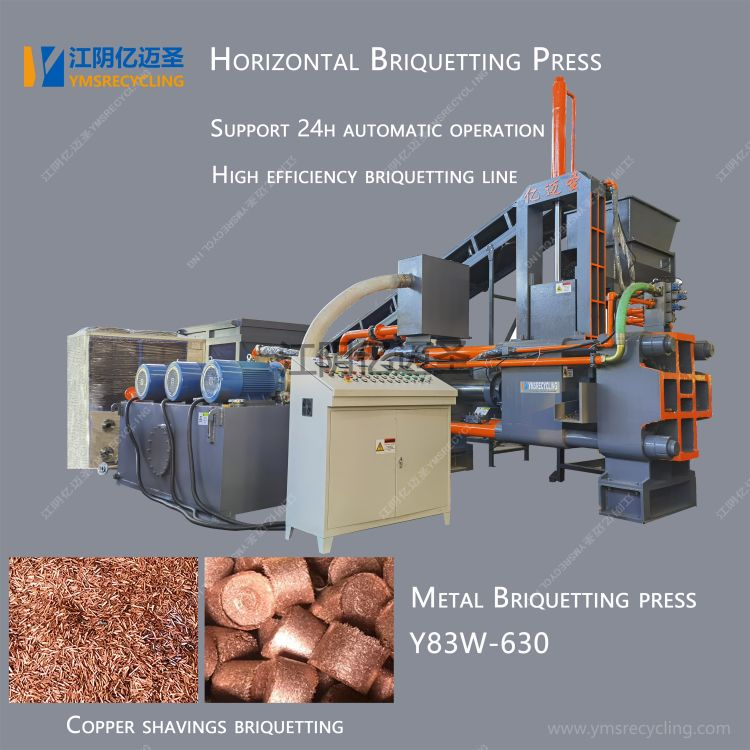

An aluminum shavings briquetting machine uses high-pressure extrusion to compress loose aluminum shavings into high-density solid blocks. Its main components include a hydraulic system, a die system, a control system, and a feeding and discharge device. The hydraulic system provides strong pressure, tightly binding the dispersed aluminum shavings under high pressure. The die system, through its rational geometric design, ensures the stable dimensions of the briquettes after forming. The control system enables automated operation, making the production process more intelligent and safer.

During operation, aluminum chips are pressed layer by layer in the compression chamber, expelling internal air and reducing the gaps between metal particles, significantly increasing the density of the briquette. High-density aluminum briquettes are not only easier to store and transport, but also reduce oxidation losses during the smelting process, thereby increasing metal recovery rates. This combined pressing process, which combines mechanical and hydraulic forces, is key to the resource recycling capabilities of aluminum chip briquetting machines.

The Important Role of Aluminum Chip Briquetting Machines in Metal Recycling

For aluminum processing companies, the recovery rate of aluminum chips directly impacts cost control and resource efficiency. Loose aluminum chips are bulky and low-density, resulting in high transportation and storage costs. They also easily absorb cutting fluids, making subsequent processing more difficult. Using an aluminum chip briquetting machine not only significantly reduces the size of the chips but also separates any attached oil, enabling dual recovery of both metal and liquid.

The compact structure of the pressed aluminum briquettes reduces fuel consumption and improves thermal efficiency during remelting. This not only reduces production costs but also reduces energy waste and carbon emissions, thus aligning with the modern industrial trend of energy conservation, emission reduction, and green manufacturing. It can be said that an aluminum chip briquetting machine is more than just a piece of equipment; it is also a crucial tool supporting the aluminum processing industry's transition to sustainable development.

Intelligence and Automation: Technological Upgrade Trends in Aluminum Chip Briquetting Machines

With the advancement of industrial intelligence, the design of aluminum chip briquetting machines is also constantly evolving. Modern equipment utilizes PLC control systems and sensor technology to fully automate the feeding, pressing, and discharging processes, significantly improving production efficiency. Intelligent systems monitor hydraulic pressure, oil temperature, and pressing density in real time to ensure consistent quality for each briquette.

Embracing Dual Environmental and Economic Values

Amidst the global push for energy conservation and environmental protection, the use of aluminum chip briquetting machines offers significant environmental benefits. Pressing and recycling not only reduces waste volume but also effectively prevents the spread of metal dust, improving the working environment. Separated cutting fluid can be recycled, reducing industrial waste discharge and contributing significantly to environmental protection.

Economically, the higher density and improved metal purity of pressed aluminum briquettes result in higher smelting recovery rates, directly improving raw material utilization. For aluminum processing companies, this translates to lower production costs and increased profit margins. In the long run, the investment in aluminum shavings briquetting machines not only quickly pays for itself but also helps companies establish a more comprehensive circular economy system.

Wide Application Prospects Across Industries

Aluminum shavings briquetting machines are not only used in aluminum profile processing plants, automotive parts manufacturers, and aerospace material companies, but are also gradually being adopted in a wider range of metal processing fields. Non-ferrous metals such as aluminum, copper, magnesium, and zinc alloys can all be recycled through similar pressing techniques. As equipment technology matures, future aluminum shavings briquetting machines will become more modular and intelligent, enabling precise control based on the characteristics of different raw materials to meet diverse industrial needs.

Aluminum shavings briquetting machines contribute to a greener future of manufacturing.

With the deepening implementation of the "Dual Carbon" strategy, the manufacturing industry is accelerating its transformation towards energy conservation and environmental protection. The widespread application of aluminum shavings briquetting machines not only promotes the development of waste recycling systems in the metal processing industry but also promotes the efficient recycling of resources. In the future industrial ecosystem, this type of energy-efficient equipment will become a key symbol of intelligent and green factories.

The Aluminum Shavings Briquetting Machine, with its significant advantages in resource recovery, cost savings, environmental protection, and automated production, is becoming an indispensable core equipment in the metalworking industry. Through continuous technological innovation and upgrading, it will continue to help the manufacturing industry develop in a more efficient, environmentally friendly, and sustainable direction, and promote the circular economy to new heights.