Scrap metal baler machines have become an indispensable core piece of equipment in the metal recycling and resource recycling industry. With the advancement of environmental protection policies and the increasing demand for metal resources, the efficient processing, transportation, and reuse of scrap metal have become key developments in the industry. Scrap metal balers, with their high-pressure forming, energy-saving efficiency, and high degree of automation, are driving the entire metal recycling industry towards a smarter and more environmentally friendly direction.

I. Working Principle and Structure of Scrap Metal Balers

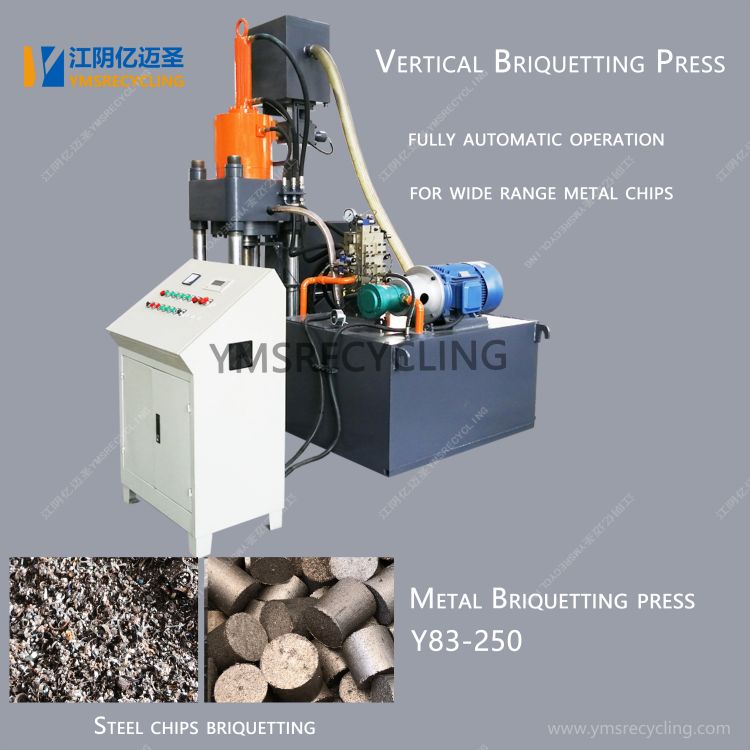

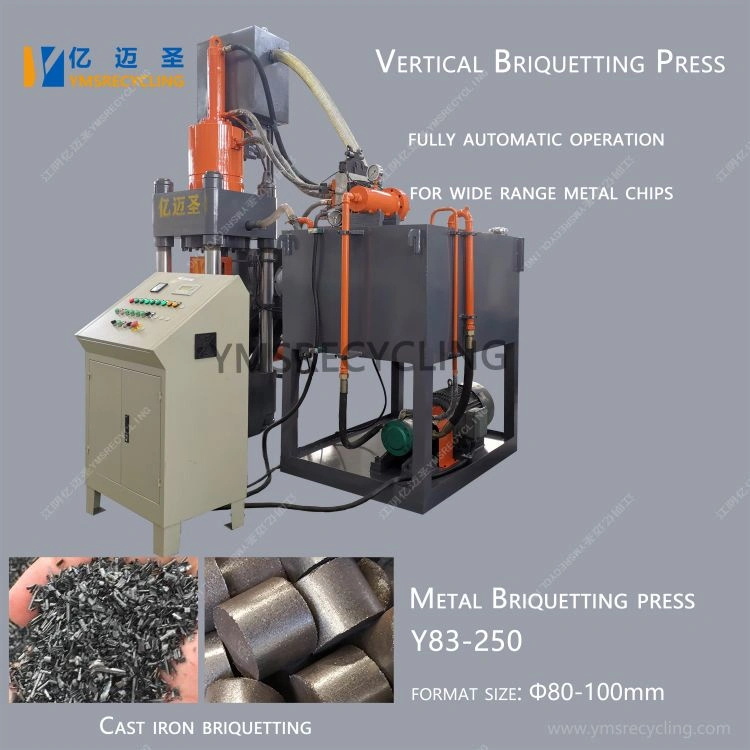

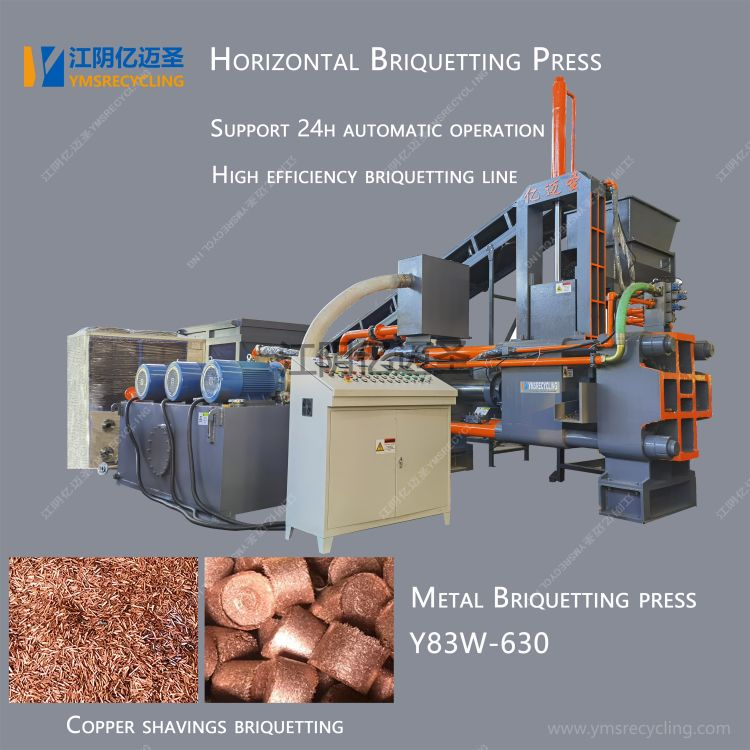

The core function of a scrap metal baler machine is to compress scrap metal into regular, high-density bales through a powerful hydraulic system for storage, transportation, and smelting. The equipment typically consists of a hydraulic system, a compression chamber, a conveying device, a control system, and a bale output system. Under high pressure, the hydraulic cylinder drives the pressure plate to perform multi-directional or unidirectional compression, rapidly compressing bulky scrap metal into compact cubic or rectangular bales, significantly reducing the space occupied by the metal during storage and transportation.

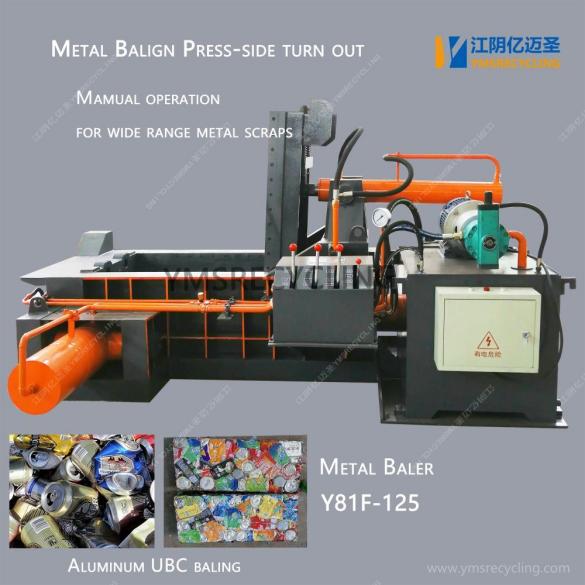

Different types of scrap metal balers can be structurally optimized based on the type of metal and processing requirements. For example, horizontal balers are suitable for larger metal materials, while vertical balers are more suitable for small and medium-sized recycling sites. The equipment's overall structure is precisely designed to ensure uniform force and stable sealing during the compression process, thereby improving the density and quality of the finished bales.

II. The Application Value of Scrap Metal Balers in Metal Recycling

In the recycled metal industry, scrap metal balers not only improve work efficiency but also significantly enhance the economic benefits of metal recycling. Due to the large size and irregular shapes of metal materials, traditional manual handling methods are difficult to achieve efficient loading and transportation. The scrap metal baler's automated compression molding significantly reduces material volume, increases transport density, and reduces transportation costs. Furthermore, the compressed bales can be more stably fed into the furnace during the smelting process, promoting smelting uniformity and reducing energy consumption.

The equipment's intelligent control system ensures a safer and more precise compression process. Operators can automatically adjust pressure, stroke, and time through the PLC control system, enabling flexible switching between different metal types and thicknesses. With the advancement of industrial automation, scrap metal balers are moving towards digital monitoring and remote control, bringing higher management efficiency and equipment utilization to recycling companies.

III. Performance Advantages and Technological Innovations of the Hydraulic System

The hydraulic system is the driving force behind the scrap metal baler machine, and its performance directly determines the compression effect and production efficiency. Modern hydraulic balers generally utilize high-pressure proportional hydraulic control technology. By precisely controlling the coordinated operation of the valve block and hydraulic cylinder, the machine ensures stable compression output even under high loads. The use of high-strength hydraulic cylinders and sealing components enhances the machine's durability and impact resistance.

In recent years, with the widespread adoption of energy-saving concepts, the hydraulic systems of scrap metal balers have continued to innovate. For example, the use of servo-hydraulic drive systems achieves energy-saving control, reducing energy consumption and lowering oil temperature rise. Furthermore, intelligent sensing technology enables real-time monitoring of pressure and flow, ensuring more stable and reliable system operation. These technological innovations not only extend the life of the equipment but also reduce maintenance and operating costs for businesses.

Scrap Metal Balers Offer Dual Environmental and Economic Benefits

Driven by the global concept of sustainable development, the use of scrap metal balers has expanded beyond improving production efficiency to include a crucial role in environmental protection and resource recycling. By compressing and baling metal materials such as scrap steel, aluminum, and copper, they effectively reduce the land occupied by scrap storage and carbon emissions from transportation, maximizing resource utilization.

Furthermore, the high-density bales produced after metal recycling can be directly fed into the smelting process, reducing energy waste in intermediate stages and improving resource utilization. This not only complies with energy conservation and emission reduction policies but also creates higher economic returns for businesses. In the context of the dual carbon emissions era, scrap metal balers are becoming a crucial support device for green manufacturing and a circular economy.

As a key piece of modern recycled metal processing equipment, the scrap metal baler machine is driving comprehensive upgrades in the metal recycling industry with its high efficiency, intelligence, and environmentally friendly advantages. It not only increases the reuse rate of metal resources but also provides strong support for businesses to achieve green production and economic growth. With continuous technological advancement and expanding market demand, scrap metal balers will continue to play a pivotal role in the global recycling sector, becoming a crucial link between resource recycling and sustainable development.