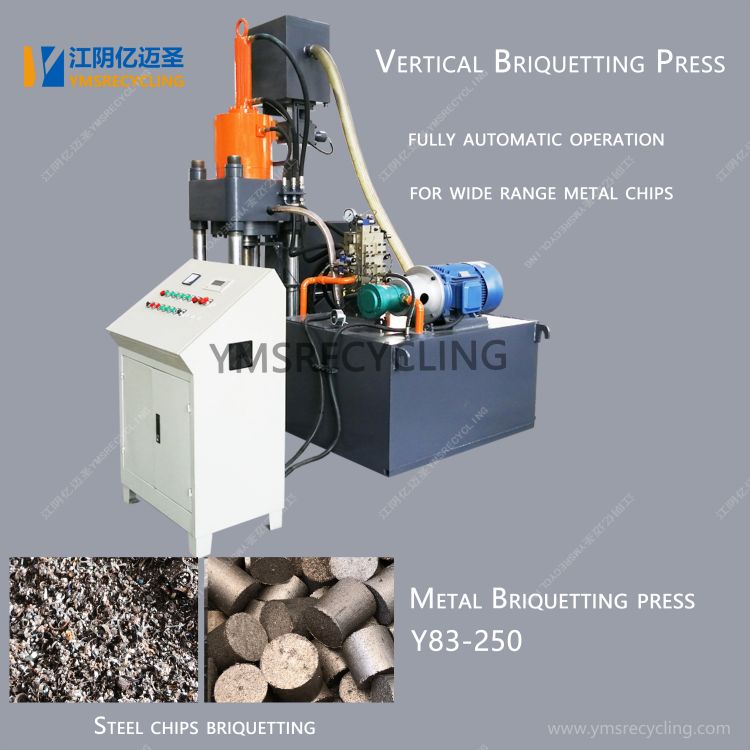

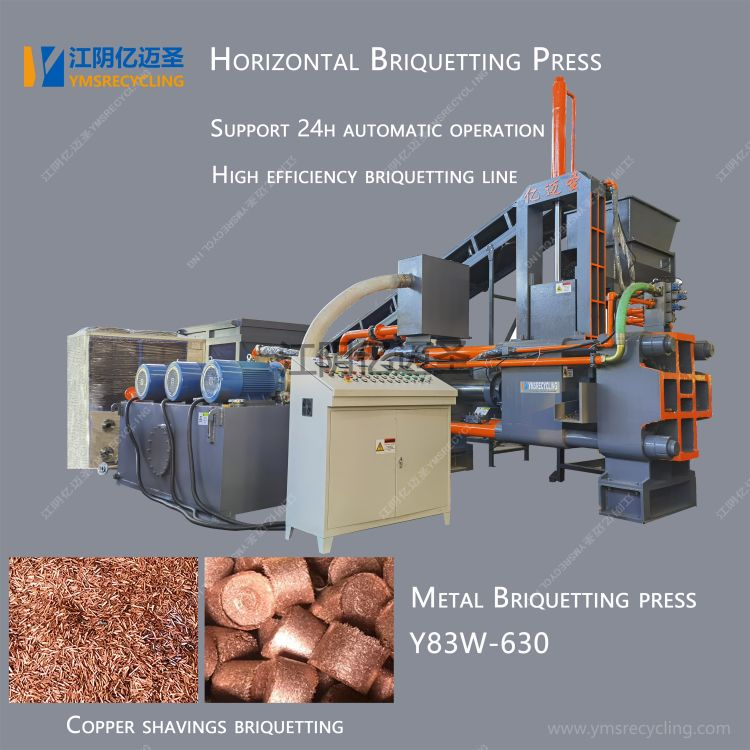

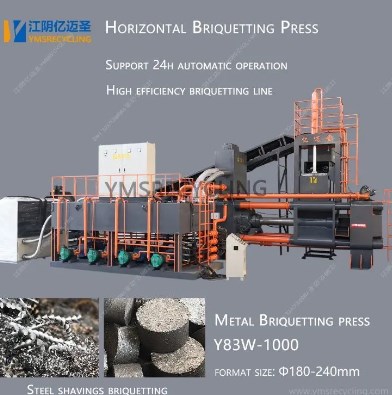

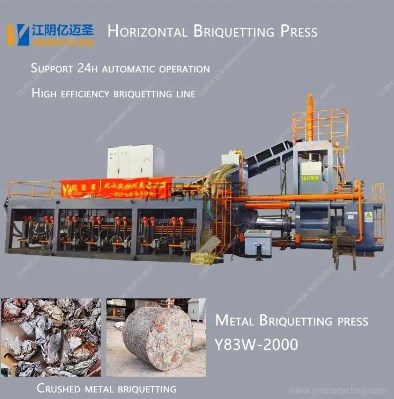

In the modern metal processing industry, efficiently handling the large amounts of metal chips generated during the cutting process has always been a key issue for companies pursuing energy conservation, cost reduction, and improved production efficiency. The emergence of scrap metal chip briquetting machines offers a new solution for metal recycling and reuse. This equipment uses high-pressure compaction technology to compress dispersed, oily, or water-containing metal chips into dense metal blocks, significantly increasing recycling rates, optimizing the workshop environment, and reducing transportation and smelting costs.

The Resource Recovery Value of Efficient Compression Technology

In industries such as machining, casting, and automotive parts manufacturing, the scrap metal chips generated after metal cutting are bulky and accumulate in dispersed piles. Direct transportation or storage not only takes up space but also leads to metal oxidation and waste. The scrap metal chip briquetting machine uses hydraulic compression technology to compact metal chips under extremely high pressure, transforming the loose metal particles into high-density metal blocks, reducing their volume while improving smelting efficiency. This process allows scrap metal to return to the production chain, achieving truly green recycling.

Furthermore, the briquetting of briquetted metal materials during subsequent smelting accelerates melting speed, reduces energy consumption, and reduces metal spatter and fume emissions in the smelting furnace, meeting the environmental and low-carbon requirements of modern manufacturing. This efficient compression and regeneration method not only optimizes production resources but also promotes the development of a circular economy.

Precision Hydraulic System Ensures Stability and Safety

The high-quality scrap metal chip briquetting machine is equipped with an advanced hydraulic control system, enabling precise pressure regulation and stable briquetting results. The machine's design fully considers the characteristics of different metal materials. Whether it's aluminum, copper, iron, or stainless steel chips, the machine can produce dense, uniformly shaped metal briquettes by optimally setting pressure and stroke parameters.

The hydraulic system's highly responsive and stable performance ensures the machine's long-term reliability. Furthermore, wear-resistant seals and an intelligent temperature control system effectively prevent oil overheating and leakage, ensuring continuous briquetting capacity even under high loads. For businesses, this equipment is not only an energy-saving tool but also a guarantee of long-term stable production.

Oil separation technology improves recycling purity.

The metal cutting process often involves the use of cutting fluids and lubricants. Traditional methods of stacking metal chips can easily lead to oil contamination and waste. However, scrap metal chip briquetting machines utilize a dedicated de-oiling device or filtration system to effectively separate cutting fluids during the pressing process, allowing the oil to be recycled and reused.

This technology not only reduces oil consumption but also prevents environmental pollution caused by oil leakage. The separated metal briquettes have a dry and clean surface, making them more suitable for subsequent smelting. This "dry" pressing technology ensures that the metal recycling process meets environmental standards and demonstrates the perfect balance between resource utilization and environmental protection.

Intelligent control facilitates automated production.

With the continuous advancement of industrial automation, modern scrap metal chip briquetting machines are increasingly focused on intelligent control in their design. Equipped with a programmable logic controller (PLC) and a touchscreen interface, the operator can monitor the pressing status, oil pressure data, and production statistics in real time. The system also automatically adjusts the pressing pressure and speed based on the characteristics of the raw material.

Intelligent control enables more precise and efficient operation, reduces manual intervention, and improves production consistency. The equipment also features automatic alarms and self-diagnostics, providing immediate feedback in the event of anomalies to ensure production safety. This automated design not only significantly reduces labor costs but also further standardizes the metal recycling process.

Environmental protection and energy conservation drive sustainable manufacturing.

As the global manufacturing industry transitions toward green manufacturing, energy conservation and environmental protection have become core business priorities. The scrap metal chip briquetting machine is a representative example of this trend. Its high-pressure forming technology effectively reduces scrap volume and transportation frequency, lowering energy consumption and carbon emissions, enabling efficient reuse of metal resources.

During operation, the low-noise hydraulic system and fully enclosed design effectively reduce dust and noise pollution, improving the workshop environment and creating a clean, safe, and low-carbon production environment. Furthermore, the closed-loop resource utilization achieved by the equipment aligns with the development of sustainable manufacturing, giving companies a dual environmental and economic advantage in their competitive advantage.

As the metal processing industry strives towards high quality and sustainability, the application value of the scrap metal chip briquetting machine is becoming increasingly prominent. It is not only a key device for improving resource utilization but also a vital contributor to the green transformation of industry. Through efficient compression, intelligent control and environmentally friendly design, this equipment is changing the traditional metal recycling model and bringing higher economic benefits and social value to the manufacturing industry.