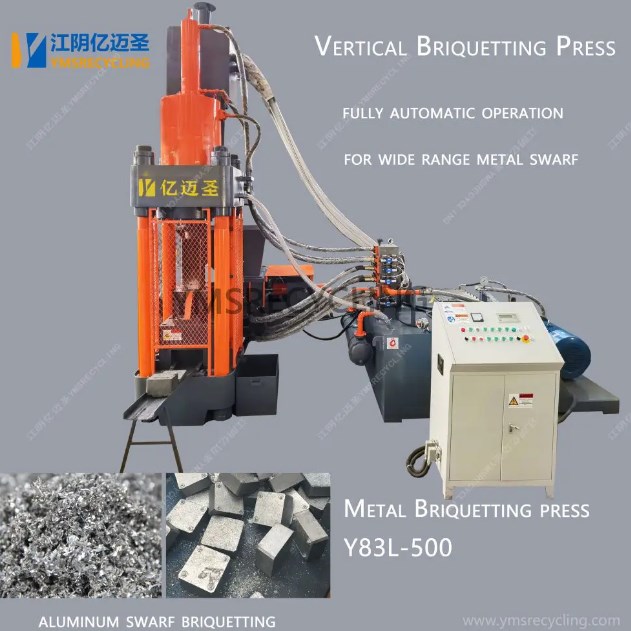

In the field of metal processing, how to efficiently handle the large amount of aluminum shavings generated during the processing process has always been the focus of the industry. As a key renewable resource processing equipment, Aluminum Shavings Briquetting Machine can not only realize the recycling of resources, but also significantly reduce the production costs of enterprises and improve environmental friendliness.

1. What is an aluminum shavings briquetting machine?

An aluminum shavings briquetting machine is a reprocessing equipment that compresses loose aluminum shavings into blocks under high pressure. Its main purpose is to reduce the volume of aluminum shavings by compression, facilitate transportation and smelting, and avoid oxidation during transportation or storage. Material loss caused by oxidation. Usually, the equipment consists of a feeding system, a compression chamber, a hydraulic system, a control system, etc., and has the characteristics of high automation, easy operation, and low energy consumption.

2. Why choose an aluminum shavings briquetting machine?

1. Significantly improve the recovery rate of aluminum chips

Through compression molding, aluminum chips can be effectively prevented from oxidation and powdering during transportation and storage, which greatly improves the remelting rate and the effective recovery rate of aluminum can usually be increased by more than 20%.

2. Reduce transportation and storage costs

Untreated aluminum chips are large in volume and small in specific gravity. After briquetting, the volume can be reduced to 1/5~1/10 of the original volume, which greatly reduces the transportation frequency and storage space and improves logistics efficiency.

3. Avoid environmental pollution and fire risks

Loose aluminum chips are prone to produce hydrogen when exposed to moisture, which poses an explosion hazard. Briquetting can greatly reduce the area of aluminum chips exposed to air and water, reducing the risk of fire and pollution from the source.

4. Improve smelting efficiency and reduce metal burning

Aluminum chips briquetting burns more completely during the smelting process, which can effectively control oxidation losses, shorten melting time, and reduce energy consumption during the smelting process.

5. Achieve closed-loop reuse of resources

Through the aluminum chip briquetting machine, manufacturing companies can form a green closed-loop process from unloading-processing-recycling-reuse, which is in line with the "dual carbon" goal and sustainable development strategy.

III. Analysis of equipment structure and working principle

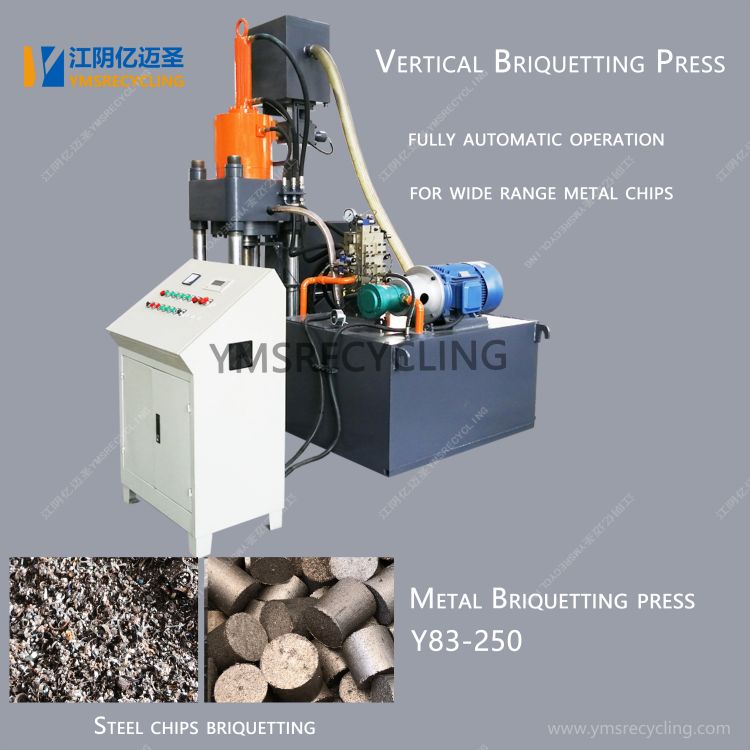

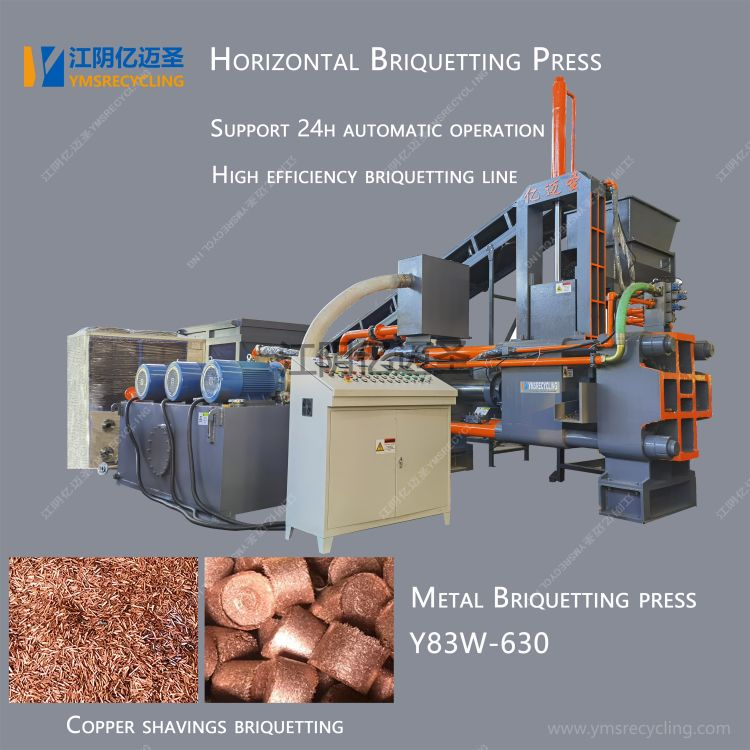

Aluminum chip briquetting machines usually adopt vertical or horizontal structures, with hydraulic or servo drive systems.

Feeding system: aluminum chips are introduced into the compression chamber through a conveyor belt or a spiral feeding mechanism;

Pre-pressing device: preliminarily compact the aluminum chips and remove some air and residual liquid;

Main pressure device: the hydraulic cylinder applies high pressure to compress the aluminum chips into high-density blocks;

Automatic discharge: through the mold exit mechanism, the briquetting is pushed out and enters the collection or transmission equipment;

Cooling and lubrication system: maintain the continuous and stable operation of the equipment and extend the service life of the equipment.

Among them, the hydraulic system is the core part of the equipment, and its stability is directly related to the density and molding efficiency of the briquetting.

4. Applicable industries and typical application scenarios

Aluminum chip briquetting machines are suitable for a variety of manufacturing industries involving aluminum processing, and common applications include:

Automotive parts processing: such as waste aluminum chips processing in engine housing, wheel hub, and frame manufacturing;

Mechanical processing enterprises: aluminum chips compression processing after unloading from CNC lathes, milling machines and other equipment;

Aerospace and precision manufacturing: recycling high-purity aluminum chips to reduce material costs;

Aluminum profile factories and recycled metal factories: as pre-treatment equipment before smelting to improve the quality of aluminum ingots.

5. Selection points and purchasing suggestions

When purchasing aluminum chip briquetting machines, enterprises should comprehensively consider the following factors:

Processing capacity and output matching: select presses of different tonnages according to the amount of aluminum chips produced;

Brick density and size requirements: select suitable briquetting shapes and densities according to the smelting process;

Control system intelligence level: It is recommended to select equipment with PLC control and remote monitoring functions;

Equipment material and structural durability: high-quality steel and wear-resistant components can significantly extend the service life;

After-sales service and spare parts supply: reliable technical support and rapid response mechanism to reduce downtime losses.

It is recommended to purchase equipment produced by well-known brands or manufacturers with good industry reputation to ensure stable equipment performance and quality.

6. Future development trend: integration of intelligence and green manufacturing

With the development of Industry 4.0, aluminum chip briquetting machines are gradually developing towards intelligence, automation, and environmental protection. Integrating MES system and IoT Internet of Things module to realize intelligent functions such as remote monitoring, abnormal alarm, and energy consumption statistics has become a new standard for high-end manufacturing companies. At the same time, the briquetting process is more energy-efficient and efficient, reducing hydraulic oil leakage and energy loss, and helping the manufacturing industry move towards a green and sustainable path.