In today's era of increasingly scarce resources and deep-rooted environmental awareness, the scrap metal recycling industry is playing an increasingly important role. As the core driving force of this industry, scrap metal recycle machine is developing at an unprecedented speed, providing strong support for the efficient recycling of resources.

Diverse types, each with its own functions

There are many types of scrap metal recycle machines, each of which plays a unique role in the recycling process. The scrap steel crusher is like a powerful "steel giant" that can easily crush hard scrap metals such as scrap steel, scrap iron, and steel slag. Its internal structure is exquisite, with one shaft connecting 4-7 fixed blades. The fixed blade is S-shaped and can be flipped and used twice. It can not only force feeding and crushing, but also discharge gas when handling flammable and explosive tanks to ensure safety. The forged hammer head in the middle of the knife disc is forged with railway wheel steel bars. It has high density and strong durability. It beats and rubs the metal material in high-speed operation, so that it forms particles and flows out from the bottom screen. At the same time, the dust collector will absorb impurities such as paint to complete the initial purification.

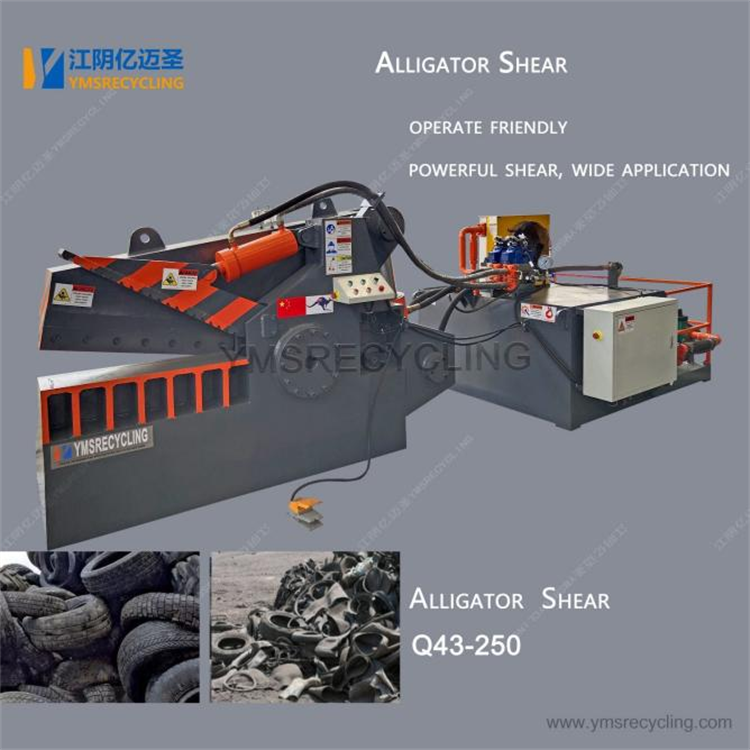

The metal shredder is like a fine "tailor", mainly used to tear scrap metal materials into smaller sizes for subsequent smelting and reuse. It is based on the strong shear force between the moving knife and the fixed knife. The high-speed rotating knife tears and shears the metal material to form uniform small pieces. Whether it is common scrap steel, scrap aluminum, or non-ferrous metals such as copper, zinc, and nickel, they can be accurately processed under its "skillful hands".

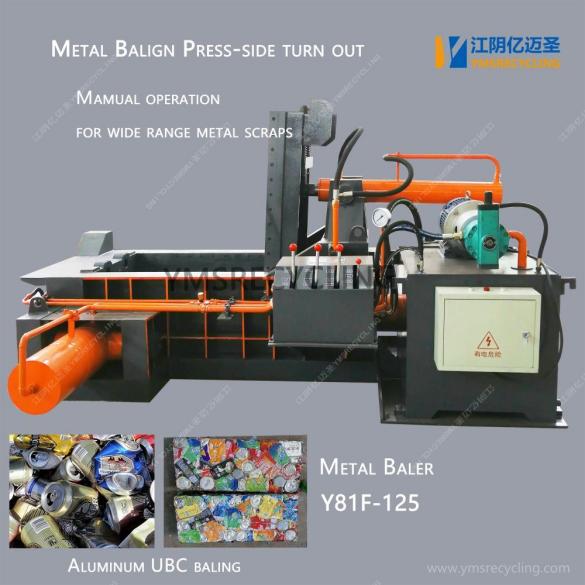

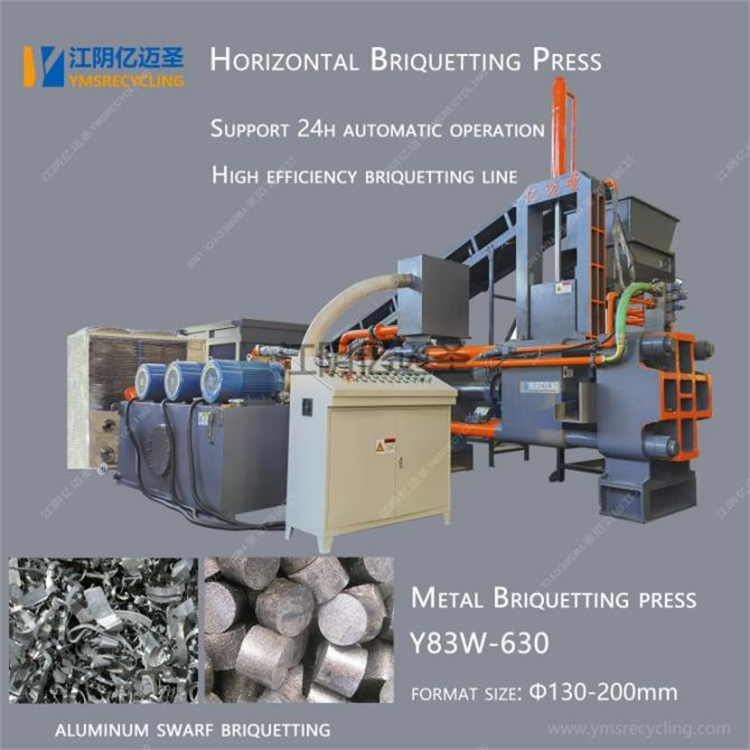

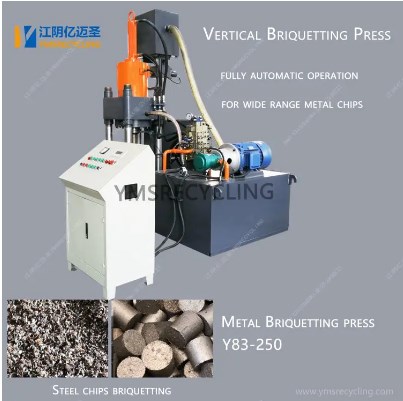

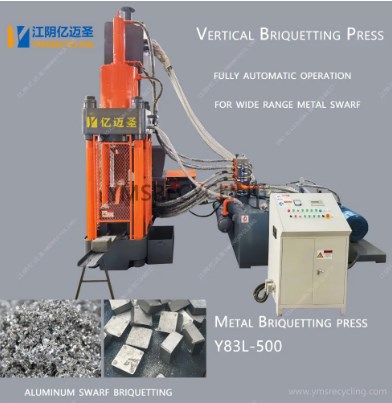

There is also a metal baler, which can be called an "efficient sorting master". It can compress scrap copper and iron into neat blocks, greatly facilitating transportation and reuse, and greatly improving the recycling rate of waste products. Especially in small and medium-sized waste recycling stations, it has become a powerful assistant to improve work efficiency and optimize working space.

Working principle, ingenious and efficient

Take the scrap steel crusher as an example, its working process is full of exquisite mechanical cooperation. The scrap steel raw materials are transported to the feed slope through the scale plate conveyor. The two rotatable, one high and one low rollers on the feed slope will first flatten it and then send it into the crushing chamber. In the crushing chamber, ten discs fixed on the main shaft and ten freely swinging hammers, with the powerful speed generated by high-speed rotation, smash, tear and crush the scrap metal crazily. After this "trouble", the scrap metal is processed into blocks or particles, passes through the lower and top grids, and falls on the vibrating conveyor. If it fails to be processed into a small enough size for the first time, it will be processed again in the crushing chamber until it meets the requirements. During the whole process, the automatic sprinkler head will cool down in time to avoid dust and ensure the stable operation of the equipment.

When the metal shredder is working, the motor drives the reducer, and the gear on the output shaft of the reducer meshes with the gear on the driving shaft, so that the driving shaft and the driven shaft rotate relative to each other at the same time, and the moving knife installed on the shaft forms a relative motion with the fixed knife fixed on the frame, thereby shearing, tearing and squeezing the metal materials entering the crushing chamber and breaking them into small pieces.

Application scenarios: Wide coverage, helping the green development of multiple industries

Manufacturing: A large amount of metal scraps and scrapped parts will be generated during the production process of the manufacturing industry. Recycling machinery can recycle and process these waste materials and convert them into production raw materials, realize the internal circulation of resources, and reduce the dependence of enterprises on external raw materials.

Automobile dismantling industry: With the increase in the number of cars, the number of scrapped cars is also increasing. Scrap metal recycling machinery can efficiently dismantle metal parts in automobiles, such as engines, frames, etc., and classify and recycle metals such as steel and aluminum in them, providing strong support for the sustainable development of the automobile industry.

Construction and demolition fields: Waste steel bars, metal pipes, etc. generated during construction and demolition can be processed and reused through recycling machinery. This not only reduces the emission of construction waste, but also provides low-cost metal raw materials for the construction industry.

In the future, the scrap metal recycle machine industry will usher in more development opportunities. On the one hand, with the popularization of environmental awareness and the continuous promotion of policies, the global demand for scrap metal recycling will continue to grow. On the other hand, the continuous advancement of science and technology will promote the development of recycling machinery towards intelligence, efficiency and refinement. Scrap metal recycling machinery is in its golden development period and will play an increasingly important role in the journey of resource recycling.