In the metal processing industry, aluminum shavings are one of the most common byproducts of production. With the widespread use of aluminum products, efficient recycling and reuse of aluminum shavings has become a crucial issue for enterprises to reduce costs and improve resource utilization. The emergence of the Aluminum Shavings Briquetting Machine provides an ideal solution to this problem. This equipment not only enhances the recycling value of aluminum shavings but also helps enterprises achieve their goals of energy conservation, emission reduction, and clean production, becoming an indispensable green equipment in modern metal manufacturing.

I. Working Principle and Core Technology of the Aluminum Shavings Briquetting Machine

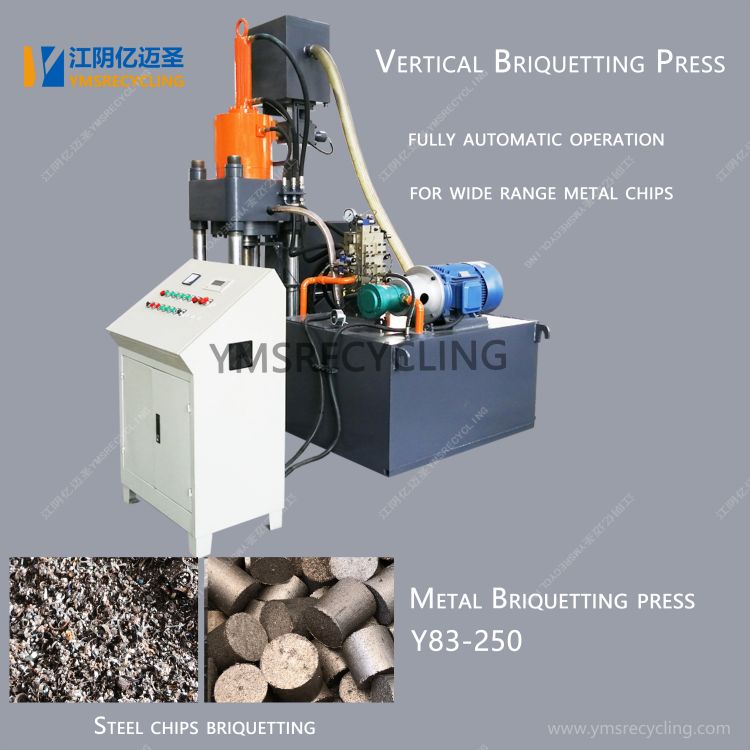

The aluminum shavings briquetting machine mainly uses a high-pressure system to compress loose aluminum shavings into high-density solid blocks, facilitating storage, transportation, and remelting. Its core working principle is to apply continuous pressure to the loose aluminum shavings using a hydraulic or mechanical pressure system, expelling internal air and oil, and forming compact metal blocks under high pressure.

Key components of the equipment include hydraulic cylinders, a pressing mold system, a feeding device, and an automatic control system. Hydraulic cylinders ensure uniform briquette density through stable thrust, while the control system enables automated feeding, pressing, and unloading processes. High-quality briquettes not only reduce smelting losses but also optimize the metal recovery rate of recycled aluminum.

II. The Value of Aluminum Scrap Briquetting Machines in Metal Recycling

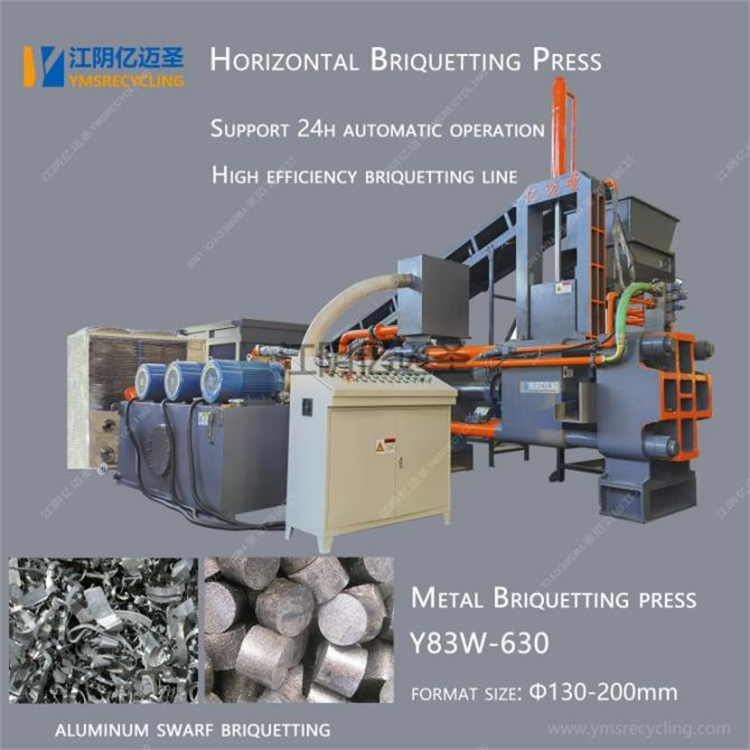

The significance of aluminum scrap briquetting machines extends beyond waste disposal; it lies in the economic and environmental value of resource recycling. Traditional aluminum scrap recycling often suffers from large volume, inconvenient transportation, and high oxidation rates. Briquetting significantly reduces the volume and increases the density of aluminum scraps, greatly improving transportation efficiency.

In the smelting process, the pressed aluminum blocks have a smaller oxidized surface area, resulting in faster melting, reduced metal loss, and higher recovery rates. Simultaneously, the effective extrusion of residual cutting fluid and grease from the aluminum scraps during pressing reduces secondary pollution and dust emissions, further improving the cleanliness and safety of the smelting environment.

III. Equipment Design and Performance Optimization Directions

Modern aluminum scrap briquetting machines emphasize the integration of automation and intelligence in their design. Automatic feeding and pressing cycles not only reduce manual labor intensity but also improve production efficiency. The equipment's hydraulic system typically employs high-pressure stable oil circuits and sealing technology to ensure stability and safety during long-term operation.

Regarding the pressing molds, high-strength wear-resistant alloy materials are used to ensure the equipment maintains good forming accuracy and service life even under high-pressure environments. The control system incorporates programmable logic controllers (PLCs) and a touch-screen interface, enabling precise adjustment of parameters such as briquetting density, pressure, and cycle time to meet the processing needs of different types of aluminum chips.

IV. The Positive Role of Aluminum Chip Briquetting Machines in Energy Conservation and Environmental Protection

Under the "dual-carbon" strategy, the energy-saving and environmental advantages of aluminum chip briquetting machines are becoming increasingly prominent. Mechanical compression reduces waste volume, saving not only storage and transportation costs but, more importantly, reducing energy consumption in the smelting process. The energy required for recycling each ton of briquetting aluminum is far lower than that required for primary aluminum production, thus significantly reducing carbon emissions.

The cutting fluid recovered during the pressing process can be purified and reused, reducing industrial wastewater discharge and lowering production costs for enterprises. The closed-loop recycling system achieved through this equipment makes the aluminum processing industry more aligned with the development direction of green manufacturing and the circular economy.

V. Industry Application Prospects of Aluminum Shavings Briquetting Machines

With the continuous growth in demand for aluminum materials from industries such as aerospace, automotive manufacturing, and electronic equipment, the output of aluminum shavings from aluminum processing enterprises is also showing a year-on-year upward trend. The promotion and application of aluminum shavings briquetting machines will become an important means for the metal recycling industry to improve efficiency and environmental quality.

On automated production lines in modern manufacturing, this equipment can be used in conjunction with machining centers, conveying systems, and metal separation equipment to form an intelligent aluminum shavings processing system, realizing the full-process management of automatic waste collection, pressing, and recycling. In the future, with the in-depth development of intelligent manufacturing technology and the Industrial Internet of Things, aluminum shavings briquetting machines will gradually evolve towards digitalization, energy saving, and high efficiency, providing stronger technical support for the green transformation of industry.

An aluminum shavings briquetting machine is not only a metal waste processing device, but also a key force driving sustainable industrial development. With high efficiency, energy saving, and environmental protection as its core values, it transforms the traditional aluminum shavings processing process into a high-value link in resource recycling. By applying this equipment, enterprises can not only maximize their economic benefits but also provide a solid technological foundation for achieving green manufacturing and low-carbon production.

In the future industrial system, aluminum briquetting machines will continue to play an important role, injecting stronger technological innovation momentum into the metal recycling industry and helping global manufacturing steadily move towards efficiency, environmental protection, and sustainability.