Amidst global resource scarcity and increasing environmental protection requirements, the recycling and reuse of scrap metal has become a key focus for major manufacturing, metallurgical, and resource recycling companies. Efficient, low-cost, and environmentally friendly scrap metal processing has become a core issue for the industry. Against this backdrop, the Hydarulic scrap metal baler machine, with its efficient compression capabilities and advanced automation, has gradually become a mainstream piece of equipment in the scrap metal recycling industry.

Demands and Challenges of the Scrap Metal Recycling Industry

With the acceleration of industrialization, the use of metals such as steel, aluminum alloys, and copper in the manufacturing industry has continued to increase, generating a massive amount of metal scrap, scrapped machinery parts, and old equipment. Traditional manual sorting and stacking methods not only consume significant space but also struggle to meet efficient transportation and reprocessing requirements. Furthermore, tightening environmental regulations require that scrap metal processing processes reduce energy consumption and carbon emissions. The emergence of the Hydarulic Scrap Metal Baler Machine addresses these multiple needs: efficient compression, reduced volume, and easier transportation and refining.

Working Principle of the Hydarulic Scrap Metal Baler Machine

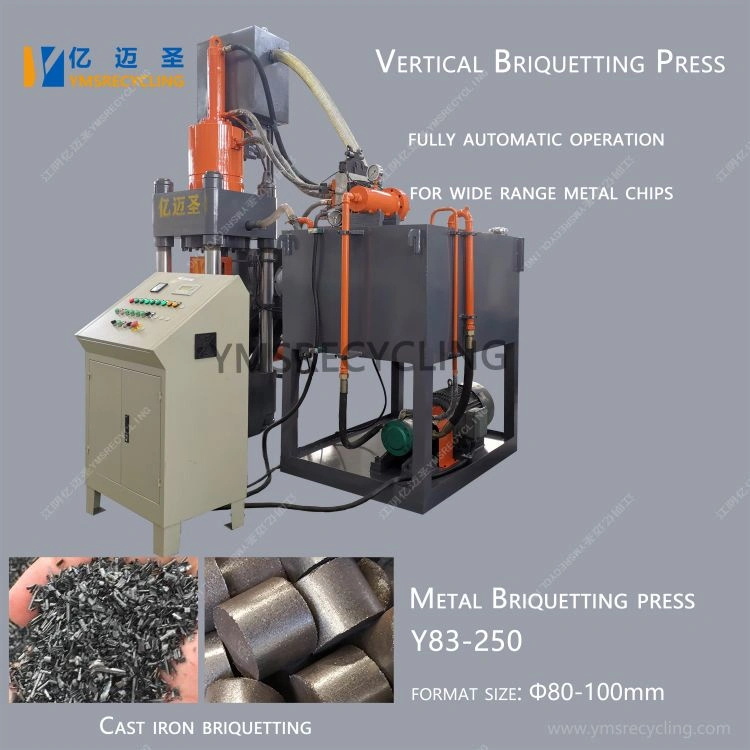

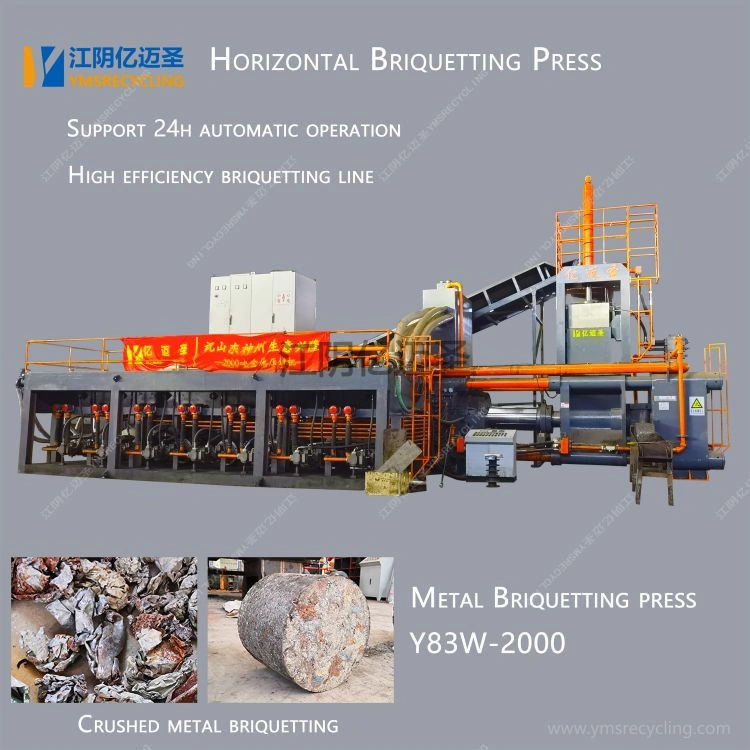

The core technology of the hydraulic scrap metal baler lies in its hydraulic system. Through the immense pressure generated by high-pressure cylinders, the machine compresses various thin materials, shavings, and metal scraps into compact, uniform metal blocks. The baled metal not only significantly reduces its volume but also increases its density, significantly reducing costs and energy consumption during subsequent transportation and smelting. Its automated control system enables continuous operation, significantly improving efficiency while reducing the risks of manual operation.

Technical Advantages and Industry Value

The Hydarulic scrap metal baler machine's value in the industry is reflected in multiple aspects. It significantly reduces the space occupied by scrap metal, saving companies storage costs. The baled metal blocks are more suitable for long-distance transportation and export trade, improving logistics efficiency. The high density of the compressed metal blocks allows for more efficient heating in the smelting furnace, reducing energy consumption and meeting energy-saving and environmental protection requirements. The hydraulic system's stable operation and long service life ensure the long-term reliability of the equipment.

Continuously Expanding Application Areas

With the diversification of market demand, the application areas of Hydarulic scrap metal baler machines are continuously expanding. In addition to traditional steel mills, aluminum plants, and non-ferrous metal smelters, large recycling companies, scrap car dismantling plants, and recycled resource trading markets have also widely adopted this equipment. Hydraulic balers of varying models and tonnages can accommodate lightweight and heavy materials, rebar, iron filings, and even scrap metal from entire vehicles, truly achieving multi-purpose applications and enhancing the equipment's market adaptability.

Market Prospects Driven by Environmental Protection Policies

Driven by global carbon neutrality and sustainable development strategies, scrap metal recycling rates are continuously increasing. Many countries are providing policy support for the recycling industry and imposing stricter standards for scrap metal handling. Hydarulic scrap metal baler machines not only improve recycling efficiency but also reduce carbon emissions during transportation, complying with the requirements of green and low-carbon development.

Future Development and Industrial Upgrading

It is foreseeable that in the future, Hydarulic scrap metal baler machines will not only be a simple compression device, but will become a key, intelligent, and integrated link in the entire metal recycling industry chain. By collaborating with automated sorting systems, conveying systems, and smelter data platforms, a complete closed-loop circular economy is formed, achieving truly efficient resource utilization. With the strengthening of global environmental protection trends, the market demand for this type of equipment will only grow, and its technological innovation will continue to drive the scrap metal recycling industry towards a more efficient and greener direction.