With the rapid development of industrialization today, the recycling of metal resources has become a key link in environmental protection and sustainable development. Hydarulic scrap metal baler machine, as an important equipment for efficient recycling and reuse of metal scrap, is widely used in many industries such as steel mills, recycling companies, and scrap recycling stations.

1. What is Hydarulic scrap metal baler machine?

Hydarulic scrap metal baler machine is a heavy equipment that uses a hydraulic system to compress scattered metal scrap into regular shaped (such as squares or cylinders) blocks. Its main purpose is to reduce the volume of metal scrap for easy transportation, storage and reprocessing. The equipment is suitable for compressing various ferrous and non-ferrous metals, such as scrap steel, scrap copper, scrap aluminum, stainless steel, etc.

2. Core advantages: Why choose a hydraulic baler?

Efficient compression, space saving

The high tonnage pressure driven by the hydraulic system can increase the metal compression ratio to more than 5:1, greatly reducing storage and transportation costs.

High degree of automation and convenient operation

Modern hydraulic balers are equipped with PLC control systems, which can realize one-button operation and fully automatic processes, effectively reducing labor costs.

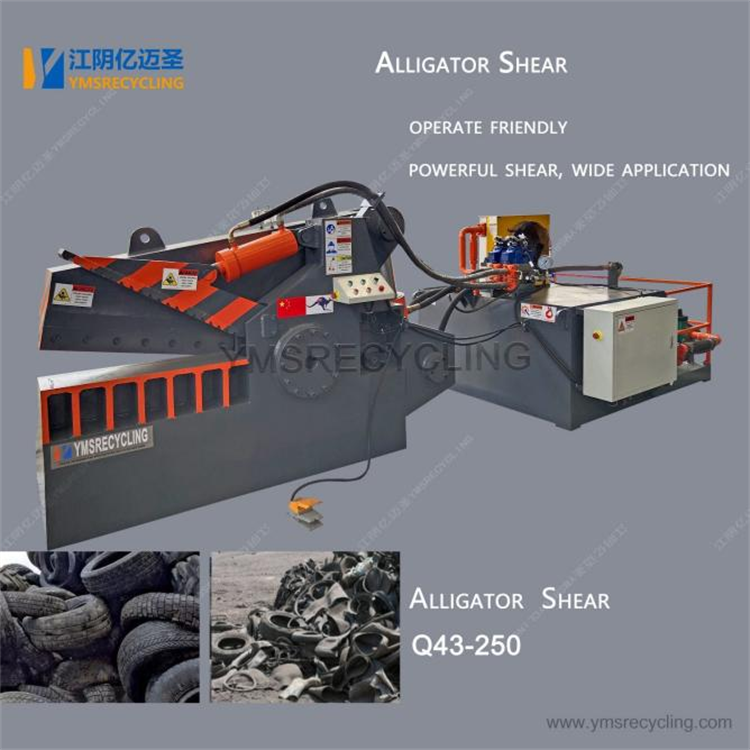

Adapt to a wide range of materials and strong versatility

Whether it is thin scrap iron, heavy scrap steel, or fragile aluminum chips and copper wire, the equipment can easily cope with it.

Sturdy structure and convenient maintenance

Adopt high-strength steel welding and one-piece molding, strong impact resistance, stable operation of the whole machine and long service life.

3. Classification of hydraulic scrap metal balers

According to different work requirements and packaging methods, hydraulic scrap metal balers can be mainly divided into the following types:

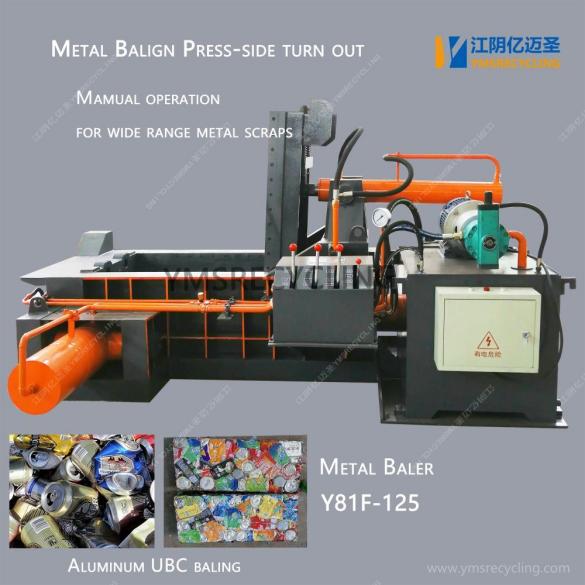

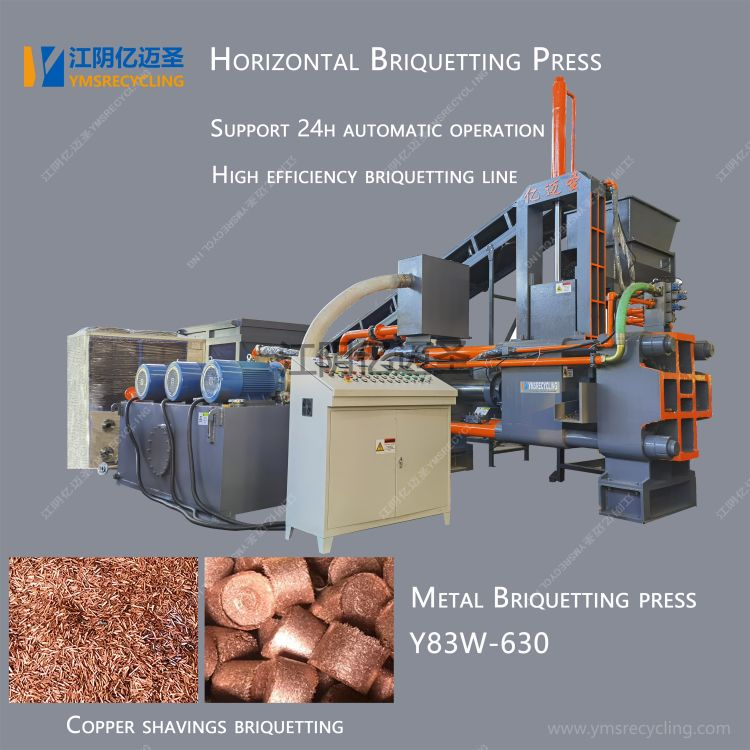

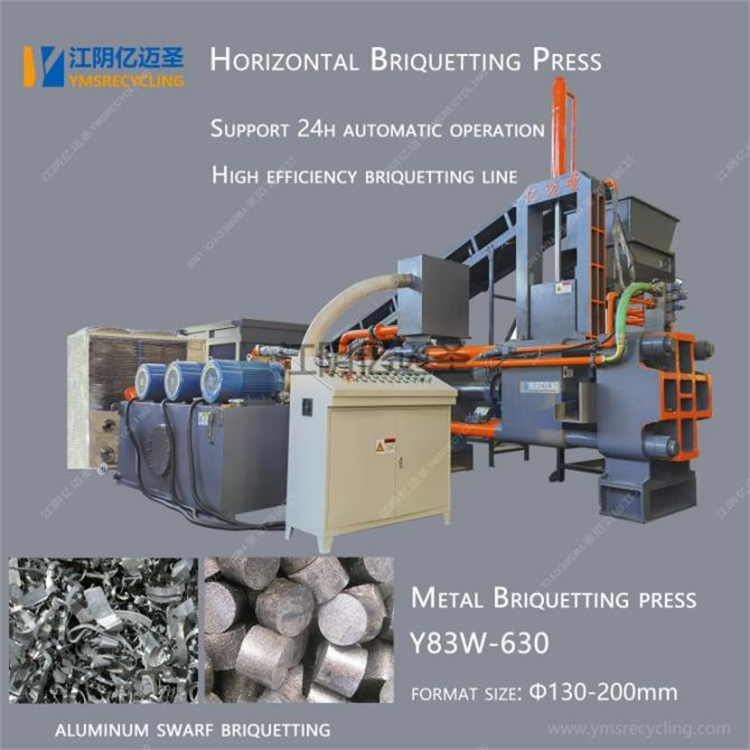

1. Horizontal baler

The horizontal structure is convenient for large-scale continuous operation and is suitable for places with large amounts of industrial waste. Its packaging methods can be divided into front packaging, side packaging, upturned packaging, etc., to meet different process requirements.

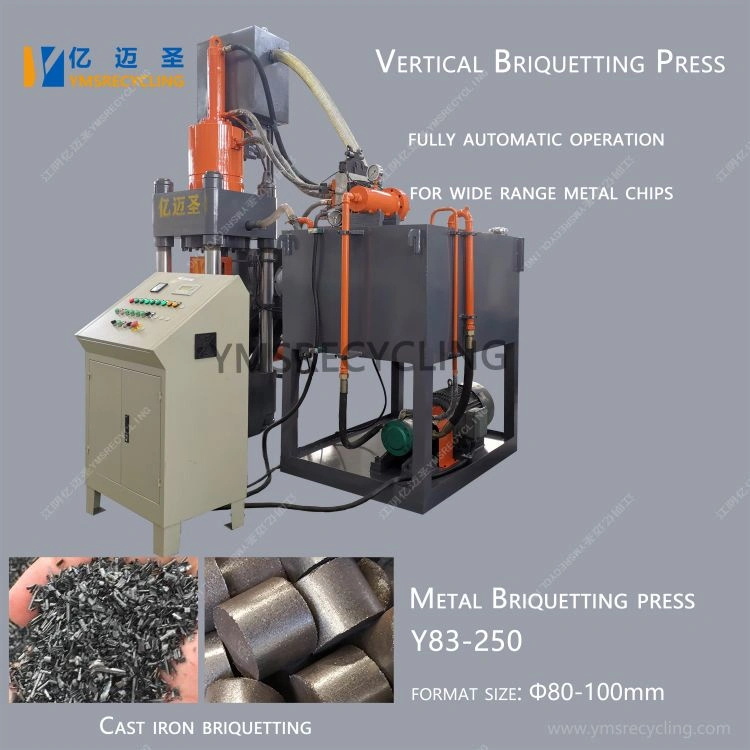

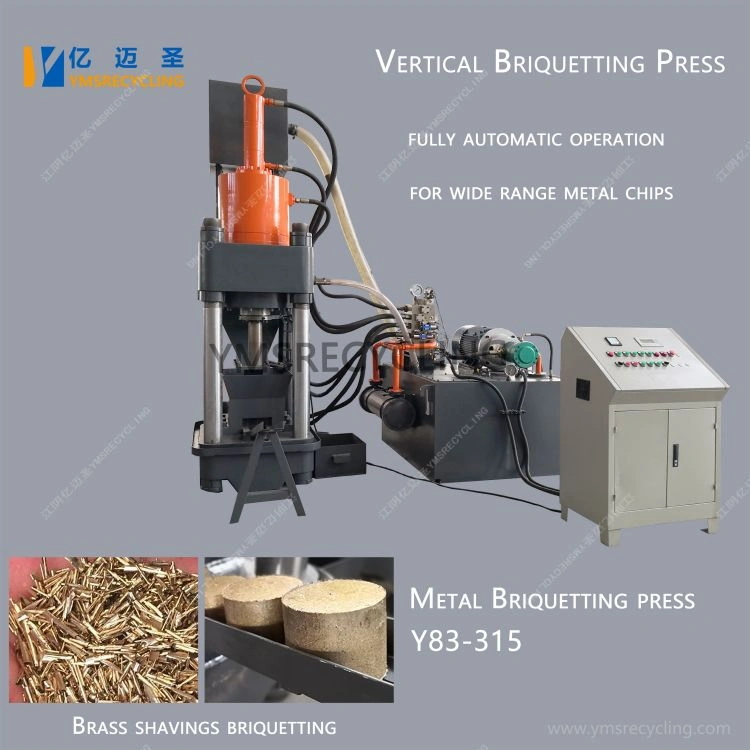

2. Vertical baler

The vertical structure occupies a small area and is suitable for use in small and medium-sized processing plants or recycling stations. It is simple to operate and suitable for medium and low frequency operations.

3. Mobile balers

With tire or track chassis, suitable for field operations or mobile operation environments, often used in car dismantling plants or on-site metal recycling.

4. Fully automatic and semi-automatic balers

The fully automatic model supports one-button start and unattended operation, suitable for automated production lines; the semi-automatic model is cost-effective and suitable for medium-sized enterprises.

4. Hydraulic system: the "power heart" of the baler

The hydraulic system is the core of the entire baler, and its performance directly determines the baling efficiency and density of the equipment. The main components include hydraulic pump station, hydraulic cylinder, control valve group and oil tank. The current mainstream on the market uses variable plunger pumps and high-pressure cylinders, which can output strong pressure in a short time and achieve rapid compression molding.

Key technical parameters include:

Compression force range: 60 tons ~ 2000 tons

Bag size: customizable, such as 300x300mm, 600x600mm, etc.

Motor power: 18.5kw ~ 110kw

Bag delivery method: automatic / manual bag delivery

Control system: PLC + touch screen / button control

V. Wide application scenarios and significant benefits

Hydarulic scrap metal baler machine is not only suitable for traditional scrap metal recycling stations, but also widely used in the following scenarios:

Steel smelting plant: Improve smelting efficiency and reduce furnace charge loss

Automobile dismantling plant: Compress scrap car bodies into transportable blocks

Waste home appliance recycling: Compress electrical appliance housings, copper and aluminum components, etc.

Port terminal: Rapid and centralized packaging of metal scrap for shipping

The recycling of metal resources is an important support for achieving the "dual carbon goals", and the Hydarulic scrap metal baler machine is the key equipment to open up the "last mile" between recycling and reuse. Choosing a high-performance baler that suits your needs can not only greatly improve work efficiency, but also create higher economic benefits and environmental value for the company. With the continuous upgrading of technology, this type of equipment will play an increasingly important role in the future metal recycling industry.