In modern industrial and urban development, scrap metal recycling is not only a crucial means of resource reuse but also a key component of sustainable development. With the continuous strengthening of environmental protection policies and fluctuations in material resource prices, scrap metal recycling machines are becoming essential equipment in the metallurgical, machinery manufacturing, and waste management industries. Leveraging advanced technologies, these machines can efficiently sort, crush, and process various types of scrap metal, saving companies costs while contributing to environmental protection.

Core Technologies of Scrap Metal Recycling Machines

The development of scrap metal recycling machines relies on the integration of multiple high-end technologies, including magnetic separation, gravity separation, and automated control systems. Magnetic separation technology can quickly identify and extract ferrous metals, efficiently separating metals from non-metals using a high-intensity magnetic field. Gravity separation, on the other hand, is suitable for non-ferrous metals such as aluminum and copper, achieving precise recovery through density differences and vibration screening. Modern scrap metal recycling machines are often equipped with intelligent control systems that utilize sensors and data analysis to optimize production processes, improve recovery rates and processing speed, and reduce energy consumption.

Structure and Function of a Scrap Metal Recycling Machine

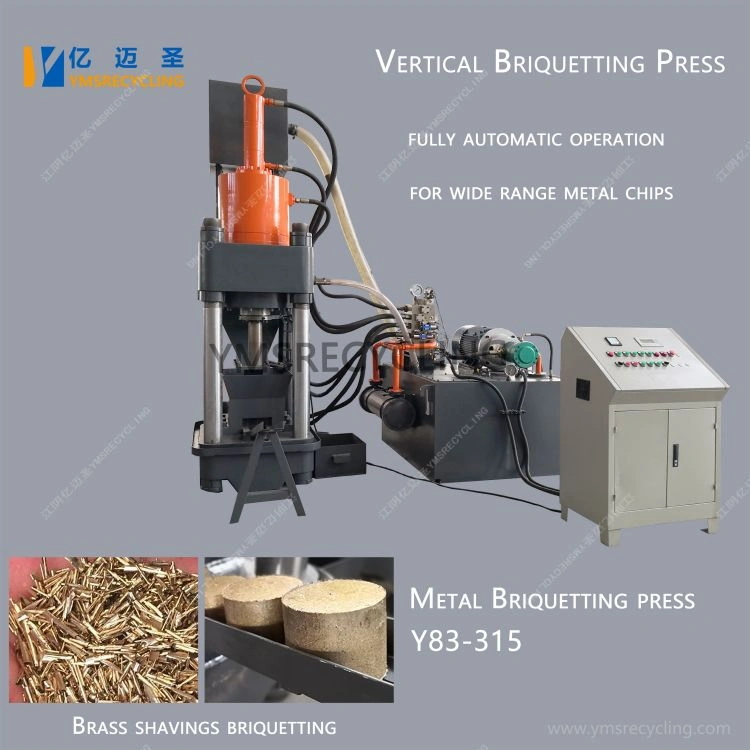

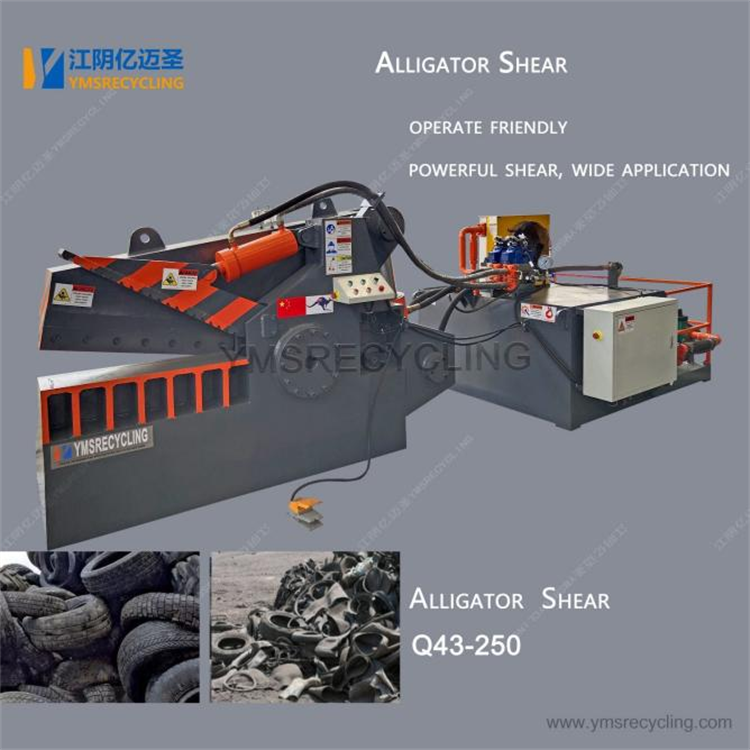

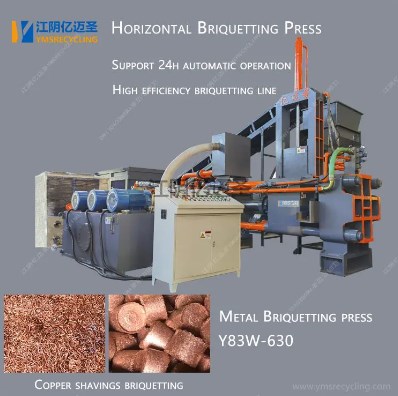

An efficient scrap metal recycling machine typically consists of a feeding system, a crushing system, a sorting system, a conveying system, and a control system. The feeding system is responsible for evenly and continuously feeding the scrap metal into the crushing unit. The crushing system uses high-strength blades or hammers to break the metal into fragments for subsequent processing. The sorting system is the core component of the recycling machine. It uses magnetic forces, airflow, and vibration to separate metals from non-metals, and also classifies different metals to improve resource utilization. The conveying system ensures the smooth flow of materials through each stage, while the control system implements automated equipment operation and fault warnings, ensuring stable and safe production.

Application Areas and Market Value

Scrap metal recycling machines are widely used in metallurgical plants, shipyards, automobile dismantling plants, and municipal waste treatment centers. In the metallurgical industry, they can recover scrap and scrap steel from the production process, reducing raw material consumption. In automobile dismantling, they can process metal parts from scrapped vehicles, realizing secondary resource utilization. With the development of industrial automation and the green economy, the market demand for scrap metal recycling machines is growing. Efficient and intelligent recycling machines not only improve business profitability but also provide important technical support for the environmental protection industry.

Development Trends of Scrap Metal Recycling Machines

With continuous technological advancements, scrap metal recycling machines are developing towards intelligent, energy-efficient, and multifunctional features. In terms of intelligence, through the Internet of Things and big data analysis, equipment can monitor operating status in real time, optimize production processes, and reduce labor costs. Regarding energy conservation, recycling machine designs prioritize energy efficiency, minimizing energy consumption per unit of output through optimized motor and drive systems. Regarding multifunctionality, equipment can not only process a variety of metals but also perform crushing, sorting, and baling on the same production line, improving process integration and production efficiency.

Environmental Protection and Sustainable Development Value

Scrap metal recycling machines play a vital role in resource recycling and environmental protection. By recycling scrap metal, reliance on mineral resources can be significantly reduced, reducing mining costs and environmental damage. Furthermore, the recycling process reduces waste landfill and incineration, reduces soil and air pollution, and achieves a balance between industrial production and the ecological environment. The application of scrap metal recycling machines is a key means of achieving green manufacturing and a circular economy, and has a positive impact on promoting sustainable social development.

As a crucial pillar of the circular economy and green industry, scrap metal recycling machines play an irreplaceable role in modern industry. With technological advancements and expanding market demand, scrap metal recycling machines will continue to evolve towards intelligent, efficient, and environmentally friendly features, creating greater value for businesses while contributing to resource conservation and environmental protection. For the metallurgical, machinery manufacturing, and waste treatment industries, investing in high-performance scrap metal recycling machines is not only an option for improving production efficiency, but also a crucial decision for implementing sustainable development.